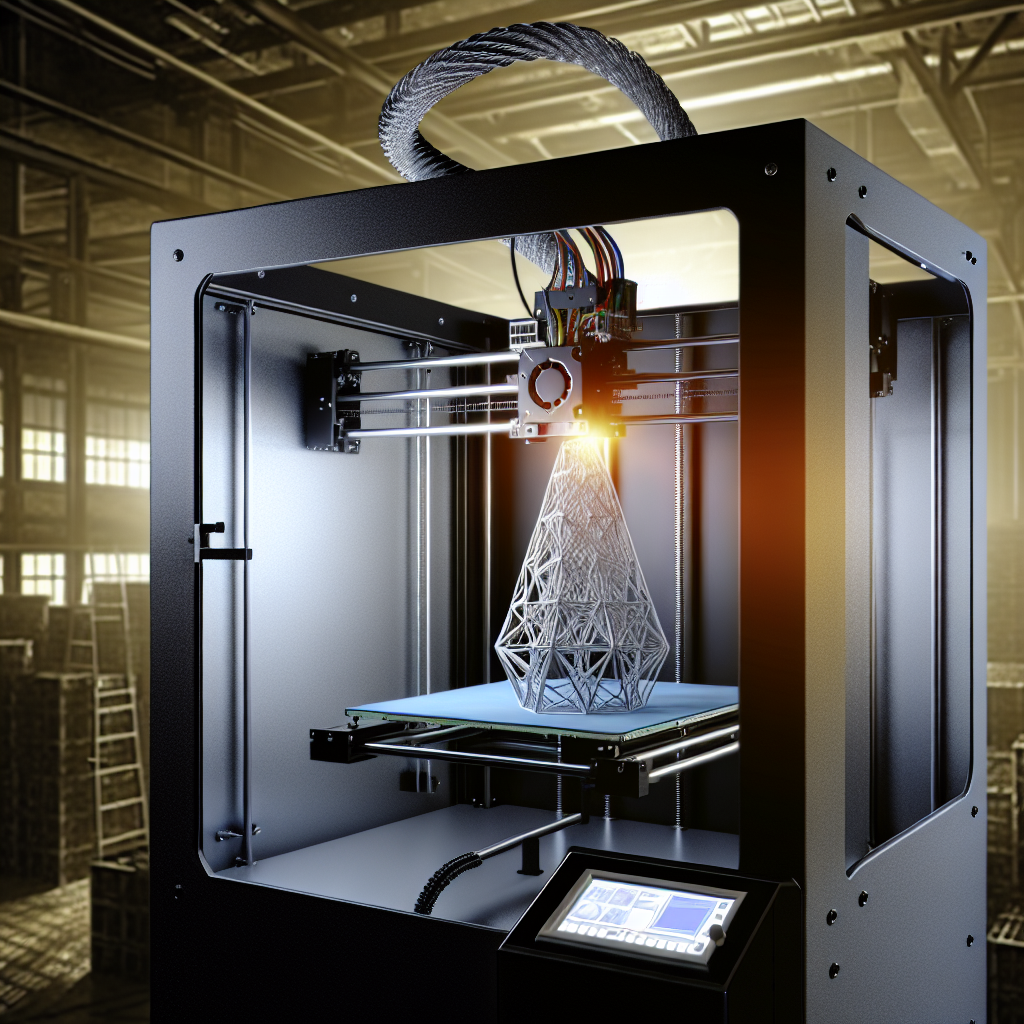

In a time when many products are created to meet customers’ insatiable needs, product developers are looking for ways to improve their manufacturing processes, specifically on the cost or speed of production. This opens up the need for rapid prototyping technologies. Rapid prototyping is the use of a machine (usually a 3D printer) in the actual design and fabrication of production parts. It is a group of techniques that are controlled by computers.

There are different techniques used in rapid prototyping, including additive and subtractive manufacturing and casting. In the 3D printing process, a variety of methods are available, including but not limited to Stereolithography (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Powder Bed Fusion, and Selective Laser Melting (SLM). This article will discuss what rapid prototyping in 3D printing is, the different types and methods, and how it compares with conventional tooling.

Description:This is the first known method for commercial 3D printing. A bed of photosensitive resin is exposed to ultraviolet light and fused at a various point in a layer-by-layer approach until completion.

Differences:Uses a bath of photosensitive resin.

Examples:Concept models or cosmetic prototypes.

Description:This is applicable to both plastics and metals. As the name suggests, a prototype is created by sintering a powder bed with a laser beam one layer at a time.

Differences:Uses a powder bed.

Examples:Prototypes and end-use parts.

Description:This quite an inexpensive method that uses a spool of thermoplastic filament. This is melted and extruded through a nozzle layer-by-layer until the process is finally complete.

Differences:Uses a spool of thermoplastic filament.

Examples:For end-use parts. Also included in it uses cases is food and drug packaging.

Description:This is a highly efficient process and used in most high strength applications. In this process, a fine metal powder is melted one layer at a time until the full solid structure is formed.

Differences:Uses a fine metal powder.

Examples:Produces medical prosthetics, end-use parts and functional prototypes.

Description:A series of thin laminates is created and bonded to one another until the object is completed. The method employs the use of a laser beam or another device that does the work of cutting

Differences:Uses adhesive coated plastic, paper, or metal laminates.

Examples:For prototyping plastic parts. Can create inexpensive yet eye-catching 3D promotional items.