Bead blasting is a surface finishing technique that uses high-pressure streams of glass bead

to remove surface impurities and create a smooth, matte texture on metal surfaces.

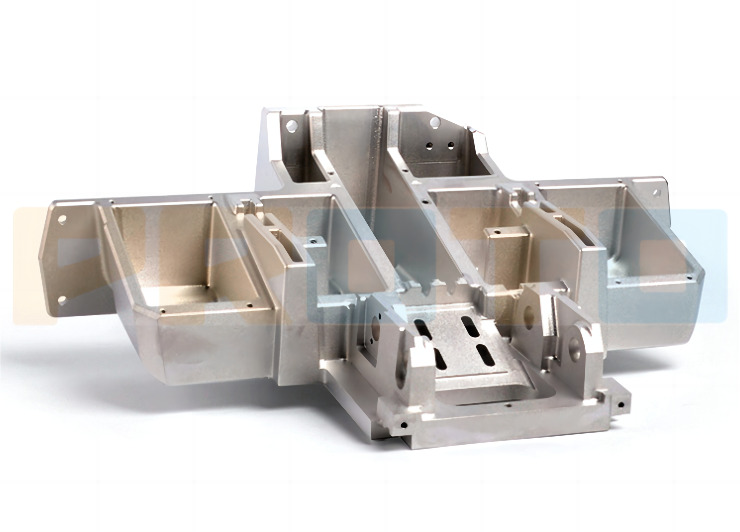

Bead blasting is a surface treatment process that involves propelling abrasive media at high speed onto a workpiece’s surface, creating a roughened, matte appearance. The process has become increasingly popular in various industries, including aerospace, automotive, and construction. Bead blasted type offers several material properties that make it ideal for different applications, including resistance to corrosion, wear, and galling. In this blog post, we will delve into the different types of bead blasting, their material properties, available processing methods, and industry and parts applications.

Types of Bead Blasting

There are two types of bead blasting – wet and dry blasting. Wet blasting uses a pressurized stream of water alongside abrasive media. This method is ideal for removing rust and paint while preventing surface damage due to its low impact power. Dry blasting, on the other hand, uses high-velocity compressed air to propel abrasive media onto a workpiece’s surface. This type of blasting produces a smoother finish and is perfect for removing coatings, paint, and oxidation.

Material Properties

Bead blasted type offers several material properties that make it highly sought after in various industries. For starters, the process provides an improved surface finish that is aesthetically appealing to the eyes. Secondly, the process increases resistance to wear, corrosion, and galling, making it ideal for machine components, automotive parts, and firearms. Lastly, the process enhances adhesion properties, making it perfect for coating and painting applications.

Available Processing Methods

There are various processing methods available to achieve the desired finish using bead blasting. These include manual blasting, automated blasting, and bead blasting booths. Manual blasting is done by progressively moving the blasting gun across the workpiece’s surface, while automated blasting is carried out using machines that blast multiple parts simultaneously. Bead blasting booths, also known as cabinets, provide a localized blasting environment and are ideal for small parts.

Industry and Parts Applications

Bead blasted type has various industry and parts applications, making it versatile and suitable for various environments. In the aerospace industry, bead blasting is used to clean turbine blades, remove surface finishes for inspection, deburring, and aerospace coatings. The automotive industry uses bead blasted type for engine components, exhaust systems, and brake components due to its corrosion resistance properties. The construction industry uses the process to remove concrete, clean surfaces before painting, and to create decorative patterns and designs.

Bead blasting has proven to be an essential surface treatment method that offers various benefits and applications. Whether you are looking to achieve a smoother finish, increase resistance to wear and corrosion or enhance adhesion properties, bead blasted type is suitable for various industries and parts applications. With the right processing method and abrasive media, beading blasting can improve a workpiece’s performance and lifespan, leaving a roughened, matte appearance that is aesthetically pleasing to the eye.