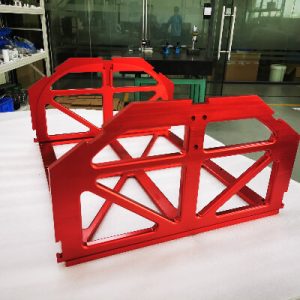

With our specialized, experienced and industry-leading technology,On-demand CNC machining for rapid prototyping and production parts.

![]()

STEP Ι STP Ι SLDPRT Ι IPT Ι PRT Ι SAT files

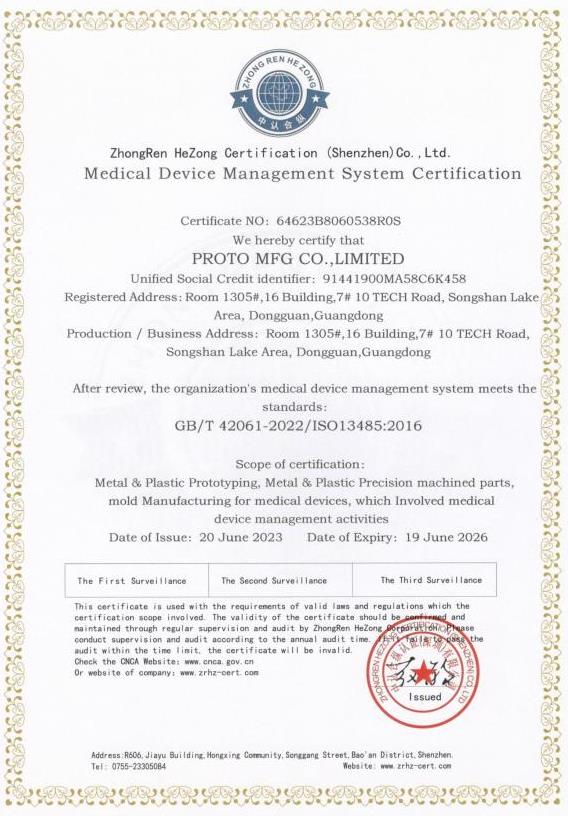

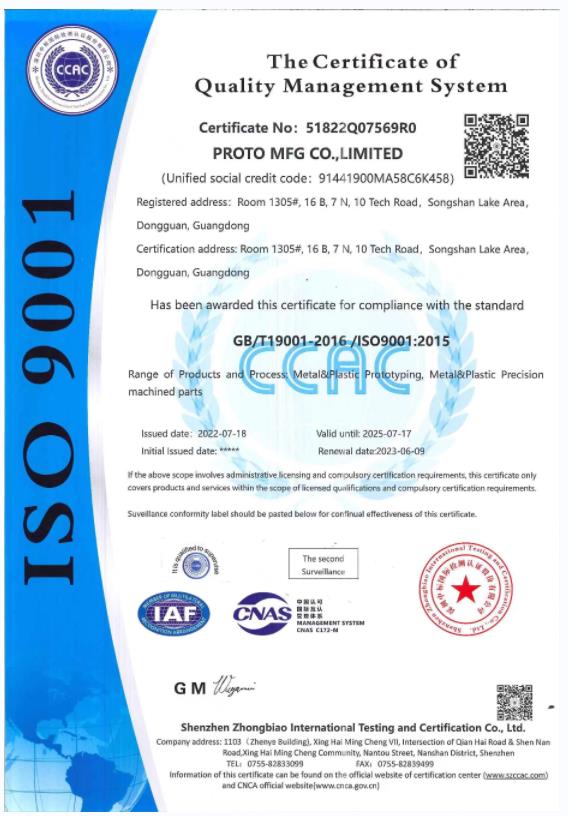

Accurate, efficient, reliable! Focus: excellent CNC machining. With ISO9001 & ISO13485, professional experience, advanced tools, ensure precise parts, timely delivery.

Upload CAD file

Securely upload your part design to our online quote builder

Receive instant quote

Our engineers provide precise quotations for you

Production

Procure materials and produce parts according to the quantity required

Quality control

Quality inspection department inspects the parts according to the drawings

Delivery

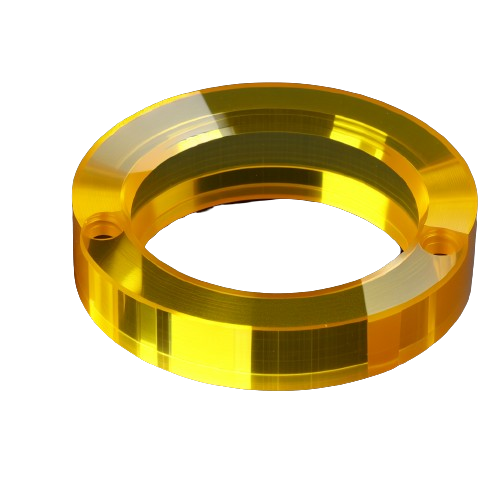

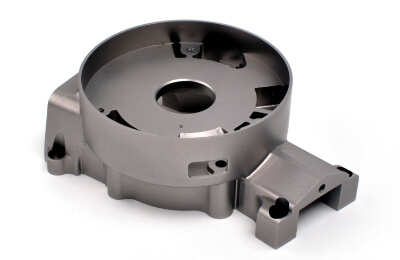

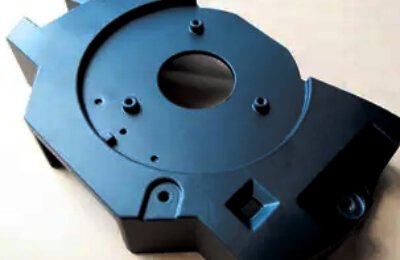

Explore our custom turning parts tailored for you, spanning rapid prototyping, low-volume, and mass production orders.

Based on specific application needs, you can select suitable materials to meet performance, durability, and cost requirements. The flexibility of CNC machining means you can choose the most appropriate materials for different project demands.

Metals

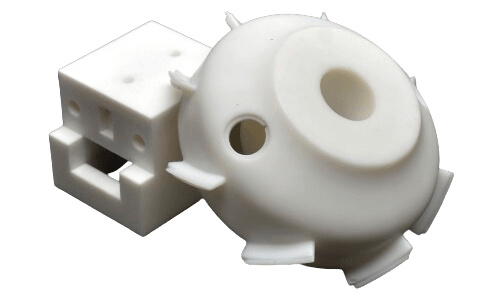

Plastic

Aluminum alloys have a good strength-to-weight ratio, high thermal conductivity, low density, and natural corrosion resistance. They can undergo anodization treatment.

The Aluminium 2017-T4 alloy offers excellent strength, corrosion resistance, and machinability, making it suitable for applications requiring high strength and lightweight, such as aerospace and automotive industries. Its machining advantages include good millability, machinability, and weldability, making it an ideal choice for manufacturing complex parts.

Aluminium 7075-T6 alloy boasts outstanding strength, hardness, corrosion resistance, and fatigue resistance. Its machining advantages include excellent machinability and milling, making it suitable for manufacturing high-strength and lightweight components, such as aerospace and sporting equipment.

Aluminum 6061-T6 alloy offers excellent strength, corrosion resistance, and weldability. Its machining advantages include good machinability and formability, making it suitable for a wide range of applications, from structural components to intricate parts in various industries.

Brass is a metal alloy with good machinability and excellent electrical conductivity, suitable for applications requiring low friction, and exhibiting a golden appearance.

Steel offers excellent strength, durability, and wear resistance, making it suitable for heavy-duty applications across various industries. Its machining performance and dimensional stability ensure precise and reliable performance in demanding environments.

Stainless steel alloys offer high strength, ductility, wear resistance, and corrosion resistance, making them suitable for various industrial applications. They are easy to machine and polish.

Alloy steel CNC parts blend steel’s strength and durability with improved features like hardness, toughness, and corrosion resistance from alloying elements like chromium and nickel. This makes them perfect for tough environments needing high strength, wear, and impact resistance.

Tool steel offers high hardness, wear resistance, and toughness, making it ideal for applications where tools are subjected to repeated impact and abrasion. Its machinability allows for precise shaping and cutting, making it suitable for producing intricate parts with tight tolerances.

Titanium, known for its exceptional strength-to-weight ratio, low thermal expansion, high corrosion resistance, and biocompatibility, is ideal for demanding applications due to its resistance to corrosion, chemicals, extreme temperatures, and superior strength-to-weight ratio.

ABS has good machinability and mechanical properties, making it suitable for manufacturing a variety of products, from prototypes to end-use parts. Its abrasion resistance and impact resistance make it an ideal choice for producing high-strength and durable parts.

Acrylic is commonly used in CNC machining due to its excellent clarity, lightweight nature, and ease of shaping. It offers high machinability, precise detailing, and a smooth surface finish, making it ideal for various applications requiring transparency and aesthetics.

G-10 is a high-strength, high-pressure fiberglass laminate with low moisture absorption and high electrical insulation as well as chemical resistance.

High-density polyethylene (HDPE) is a slippery plastic commonly machined into plugs and seals. It serves as an excellent electrical insulator and possesses resistance to moisture and chemical corrosion.

Nylon, also known as polyamide (PA), is an engineering thermoplastic renowned for its excellent mechanical properties, high chemical resistance, and abrasion resistance. Glass-filled Nylon enhances these qualities with increased rigidity, strength, hardness, toughness, and dimensional stability, making it suitable for applications requiring mechanical damping or electrical insulation, including electrical housings, washers, medical devices, and aerospace components.

Polycarbonate (PC) is a thermoplastic renowned for its high toughness, excellent impact strength, and good machinability, with the added capability of being optically transparent. It is widely used in manufacturing, with notable applications including first-generation MacBook laptops, safety goggles, and optical disks. Additionally, polycarbonate is heat-resistant, impact-resistant, flame-retardant, and among the most recycled plastics globally.

PEEK is a high-performance engineering thermoplastic known for its exceptional mechanical properties and chemical resistance across a broad temperature range. It serves as a lightweight alternative to soft metals in high-stress and high-temperature applications, boasting resistance to moisture, wear, and chemicals.

POM, an engineering thermoplastic, is utilized in precision components that demand superior stiffness, minimal friction, and outstanding dimensional stability.

PPS is a high-performance engineering plastic prized for its remarkable temperature resistance, dimensional stability, and electrical insulation. With superior mechanical strength, chemical resistance, and flame resistance, it finds widespread use in automotive, electronics, medical, and industrial applications.

PTFE, an engineering thermoplastic, boasts exceptional chemical and thermal resistance, along with the lowest coefficient of friction among all known solids.

PVC ranks as the third most utilized plastic, offering commendable mechanical properties, outstanding resistance to chemicals and weather, and notable toughness.

Ultra-High-Molecular-Weight Polyethylene (UHMW) is a durable plastic renowned for its low friction, abrasion resistance, and high impact strength, making it ideal for applications such as chute/hopper liners and machine guards.

ULTEM 1000 is a durable, translucent amber-colored plastic known for its exceptional strength, stiffness, and heat resistance, often preferred for its superior dielectric properties over Nylon or Delrin. Commonly used in industrial equipment, medical devices, and electronics.

Our surface finishing options can be tailored to meet the needs of different projects, ensuring turned parts meet appearance and performance requirements.

Get instant CNC quotes by uploading your design files, including color, material, surface treatment, and required quantity, without the need to write a quote request email.

PROTO MFG’S CNC Machines are built to provide maximum accuracy whether they are tasked to produce one metal machined part or thousands of machined parts.

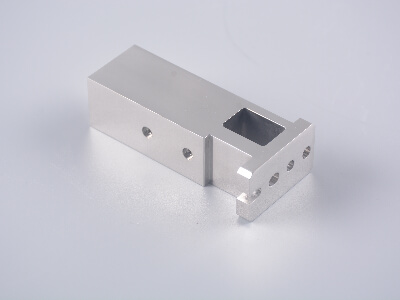

PROTO MFG’S tolerance Can be 0.005 to 0.01 mm

Direct from CNC machining factory, offering cost-effective solutions for your precision parts needs.

PROTO MFG’s Tesla Supplier Code: 204021

PROTO MFG Obtains ISO 13485:2016 Management System Certification!

1.Required strength

Consider what type of strength characteristics are needed for the part, such as tensile strength, compression strength, or yield strength. The material choice will depend on the intended application and the load that the part will be subjected to.

2.Wear resistance

Consider whether the part will be subjected to abrasion or friction and choose a material that can withstand those conditions for the required duration of use.

3.Corrosion resistance

Consider whether the part will be exposed to harsh environments that could cause corrosion or rust over time, and choose a material that can resist or minimize these effects.

4.Machinability

Consider whether the material will be easy to machine and produce good surface finishes without excessive tool wear or breakage.

5.Cost

Consider the cost of the material, taking into account how it will affect the overall cost of the part, including machining costs, finishing costs, and any subsequent assembly requirements it may have.

The cost of plastic CNC machining depends on the complexity and size of the part as well as the type of plastic that is used. These variables will influence the type of machine that is required, the time it takes to produce the part, and the cost of the raw material.

We use machine learning algorithms to calculate the exact cost of any machinable part directly from a CAD file, based on millions of CNC machining orders we’ve previously processed. Simply upload a CAD file to generate a quote: Get an instant CNC machining quote.

Metal machining is a manufacturing process that involves cutting a piece of raw metal until a final desired shape or object remains. With CNC metal machining, unwanted geometry is cut from a raw block of metal, bit by bit with a computer numerically controlled (CNC) milling or turning cutting tool, very precisely and allows complex parts to be produced with great accuracy.

The standard prototype and production machining tolerance at Protolabs is +/- 0.005 in. (0.13mm). This means any part feature’s location, width, length, thickness, or diameter will not deviate by more than this amount from nominal. For example, the 1 in.

ISO (International Organization for Standardization) created ISO 2768 as an international manufacturing standard that simplifies drawing specifications for CNC machining tolerances. Creating this international standard and its implementation make designing and manufacturing more accessible and convenient.