Small Quantities,Durable Components with Production-Level Quality

STEP Ι STP Ι SLDPRT Ι IPT Ι PRT Ι SAT files

Maintaining high-quality standards and requirements even with low production volumes during the manufacturing process.

Urethane casting is ideal for prototyping elastomeric parts like complex gaskets and overmolds. It offers nearly limitless complexity, including sharp internal corners, and designs without draft or uniform wall thickness that can’t be injection molded.

Get instant CNC quotes by uploading your design files, including color, material, surface treatment, and required quantity, without the need to write a quote request email.

Choose from a variety of possible materials and surface finishes for your vacuum castings.

We use high-quality elastomeric materials to manufacture intricately structured vacuum-cast plastic parts, ensuring your prototypes and small-batch components closely resemble the intended final product.

Direct from CNC machining factory, offering cost-effective solutions for your precision parts needs.

PROTO MFG holds ISO certification, ensuring our products and services meet international quality standards. We offer manufacturing analysis and quality control to deliver parts that adhere to the highest standards.

PROTO MFG’S tolerance Can be 0.1 mm

You can choose from a variety of vacuum casting materials based on your project’s needs. These resins typically mimic the performance and appearance of common plastic materials. We categorize our urethane casting materials to assist you in making the best decision for your project.

Advantages of using ABS-Like materials for vacuum casting include excellent mechanical properties and surface finish, making them ideal for producing high-quality prototypes and low-volume production parts.

Acrylic-Like materials offer excellent transparency, UV resistance, and impact strength, making them ideal for applications requiring optical clarity and durability.

Polycarbonate-Like materials provide outstanding impact resistance, optical clarity, and heat resistance, making them suitable for applications requiring toughness, transparency, and thermal stability.

PMMA (Polymethyl Methacrylate) offers excellent transparency, outstanding optical performance, and weather resistance, making it suitable for applications requiring high transparency and weatherability.

Elastomers are a type of polymer material known for their high elasticity and deformability. Its typically exhibit excellent resistance to wear, chemicals, and high temperatures. It’s flexibility, malleability, and durability make them indispensable materials in many applications.

Prototyping

Vacuum casting involves low-cost tooling to create prototypes in a more accessible and cost-effective manner. It allows for high-quality prototypes with various materials and design changes. Easily test your designs and prepare for functional testing.

Market Testing

We assist you in creating vacuum-cast products suitable for market and consumer testing, concept modeling, and user evaluations.

On-Demand Production

Urethane casting is an excellent choice for custom and first-run production. It allows you to economically and efficiently test product quality before full-scale production begins.

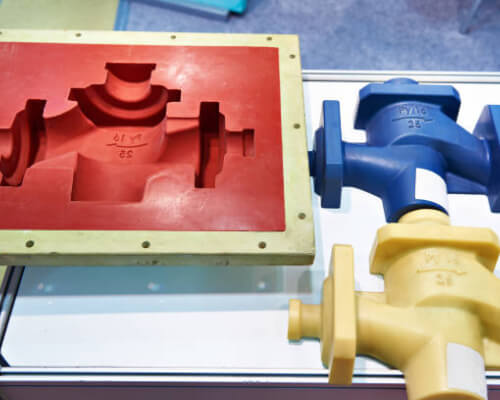

Step 1: Make a Prototype Step 2: Make the Silicone Mold Step 3: Urethane casting

Urethane casting, also known as silicone molding or Vacuum casting, is an economical alternative to pre-series injection molding of plastic parts. Usually, the mold uses CNC machined parts or 3D Printing parts/SLA parts as prototypes, made of silicone material, and polyurethane PU material is cast through the process of vacuum injection to make parts. Duplicate parts can accurately replicate the structure, details, and texture of the prototype and provide a consistent surface finish to obtain results similar to injection molding production.

Generally, before mass production of products, small batch production will be carried out in advance to test product performance and market demand, so as to avoid blind production causing product backlog and unnecessary losses.

If it is a pre-series production, the preferred process is urethane casting, because this process is suitable for the one-time molding of complex structural workpieces, which can effectively shorten the development time and save research and development costs.

The quality of the complex depends on the quality of the prototype,for complex shapes, SLA printing is considered.

We can spray texture or matte effect or silk screen on the surface of the prototype to simulate the final mold texture of the product. The silicone mold will accurately reproduce the details and texture of the prototype, and the surface of the final replica will maintain a high degree of consistency with the original. And the tolerance can be within 0.1mm.

The pouring mold is made of liquid silicone, also known as RTV mold.

Silicone rubber’s chemical stability, self-release properties and flexibility allow for minimal shrinkage and efficient replication of part details from prototype to mold.

The production steps of the silicone mold are as follows:

1. Adhesive tape is applied to the flat places around the prototype for easy mold opening later, which will also become the parting surface of the final mold.

2. The prototype is suspended in a box, and glue sticks are placed on the parts to set the sprue and vent holes.

3. Fill the box with silicone and vacuum it, then cure it in an oven at 40°C for 8-16 hours, depending on the volume of the mold.

4.After the silicone rubber is cured, the box and the glue stick are removed, and the prototype is taken out of the silicone to form a cavity, and the silicone mold is made.

PROTO MFG’s standardized operating procedures ensure accurate part reproduction and consistent mechanical properties. Our technicians control all operating parameters: mixing, venting, agitation, preheating, pouring and demoulding, providing near-perfect replicas of prototypes. The process of vacuum injection molding is as follows:First put the silicone mold into the oven and preheat to 60-70℃.

To prepare polyurethane resin, preheat it to about 40°C before use, mix the two-component resin in the correct ratio, then fully stir and degas under vacuum for 50-60 seconds.The resin is poured into the mold inside the vacuum chamber, and the mold is cured again in an oven. Average curing time: 1-3 hours for small pieces, 3-6 hours for large pieces. Remove the casting from the silicone mold after curing. Repeat this cycle.