Series Production, also known as low-volume production, typically ranges from 50 to 10,000 pieces. Embracing series production is an effective strategy for mitigating new product marketing risks. It allows companies to test production processes, minimize tooling expenses, reduce overall costs, and transition towards more flexible manufacturing practices.

STEP Ι STP Ι SLDPRT Ι IPT Ι PRT Ι SAT files

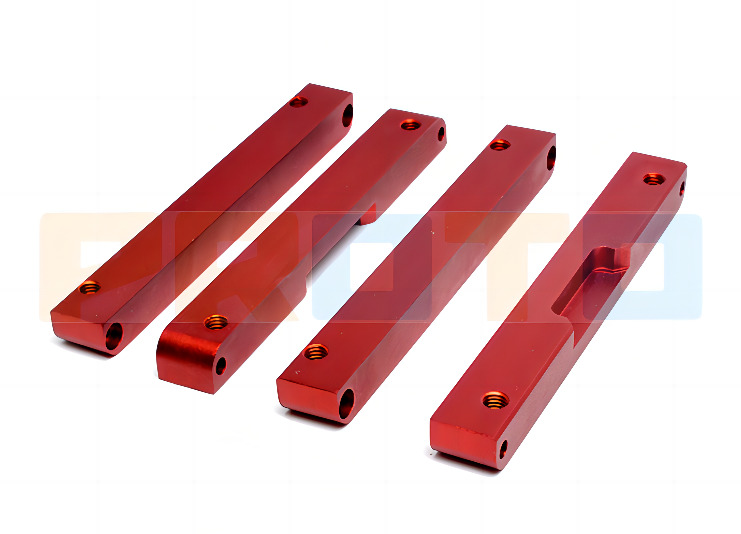

Available manufacturing technologies including: CNC machining, sheet metal, urethane casting, 3D printing.

CNC Machining, URETHANE Casting, Injection Molding, Sheet Metal, 3D Printing

PROTO MFG’s Series Production for Custom Parts

Series Production is also called low-Volume Production. We define it as 50 pcs to 10,000 pcs.

The best way of mitigating new product marketing risks is to adopt a series production.

Series Production will help the company to test production, reduce tooling, cut costs, and shift toward flexible manufacturing.

Series Production / Low-volume production used as:

3. PROTO MFG’S Series Production-Reduce cost

Series production solutions require very little cost and can be used to test the product’s function, market, feasible manufacturing, and popularity before committing to mass production. If you get any negative feedback, you can stop the investment in the project in time, which saves a lot of cost compared to direct mass production.

4. PROTO MFG’S Series Production-For custom products or device

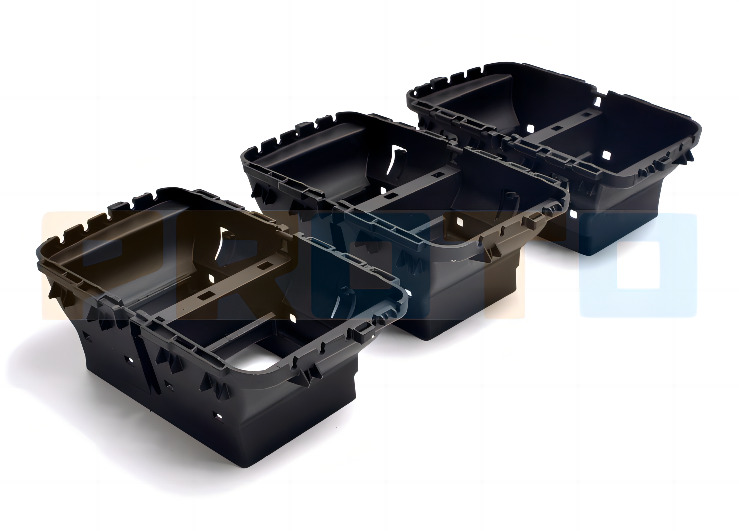

No matter in the consumer electronics industry, industrial product industry, or high-tech product industry, people are more and more inclined to precise and purposeful procurement, which means that many products or equipment will not be mass-produced industrially. Small batch production can just solve this kind of customized production service.

1. PROTO MFG’S Series Production-Bridge between rapid prototyping and mass production.

Series production is used to bridge between rapid prototyping and mass production. It can reduce risk of manufacturing or assembly issues before mass production.

2. PROTO MFG’S Series Production-Test market reaction at relatively little cost

Series production can gauge the market’s response to a new product. Instead of investing amounts in expensive tooling for final production, a small number of parts can gauge the response of the market. Then the company can decide if they should expand the production.

Advantages of PROTO MFG’S Series Production

NDA Signed

Deliver on-time

DFM report support

100% / SQL inspection

Quote Within 24 hours

Speed and affordability

ISO 9001:2015 certified

Fast turn-around production

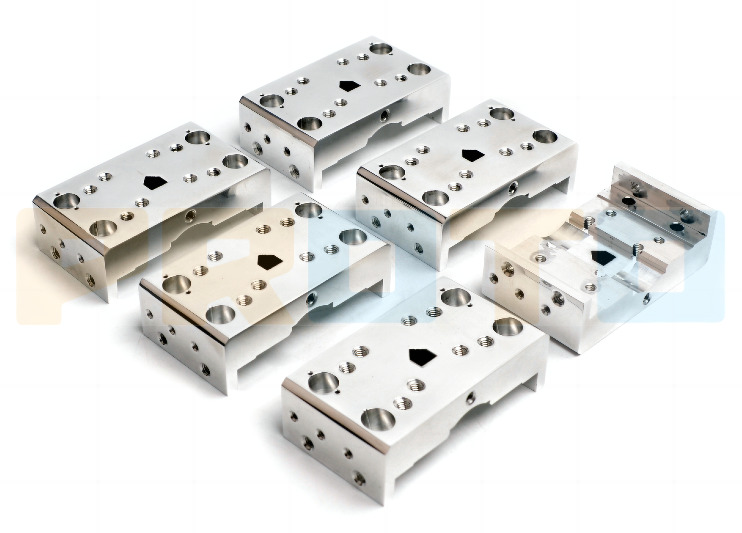

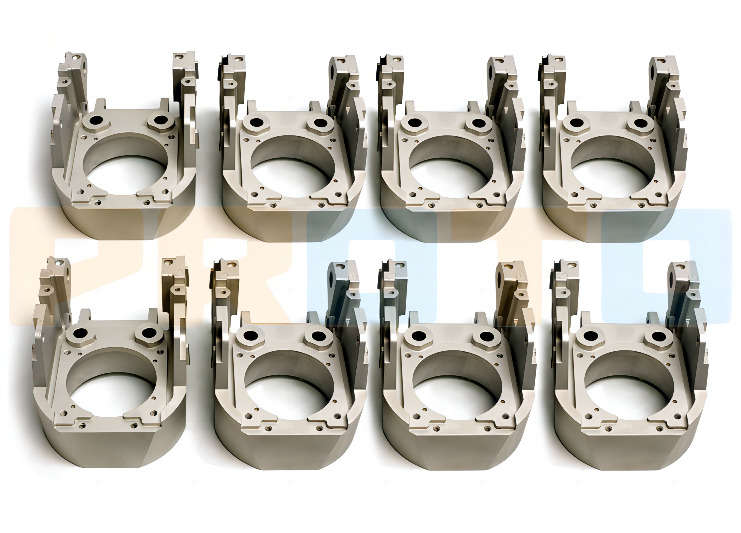

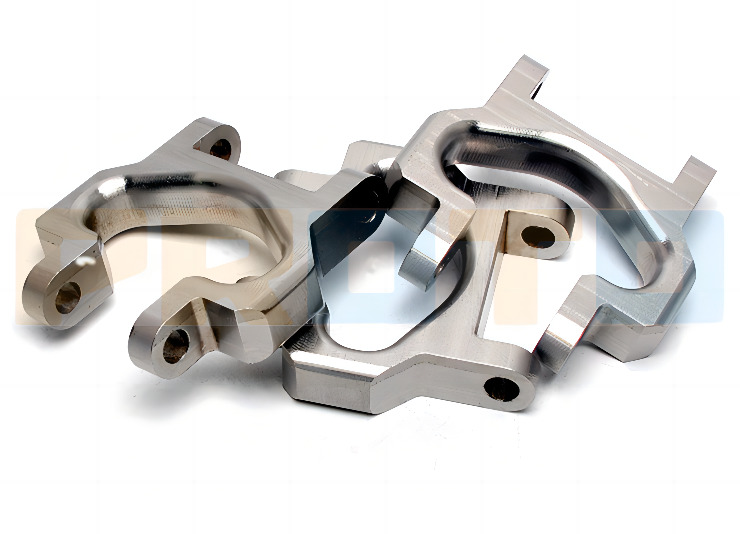

CNC machining: CNC turning, CNC milling

CNC turning & milling,

5 Axis CNC machining

Swiss Lathe

Urethane Casting

3D Printing

Rapid Tooling

Wire Cutting

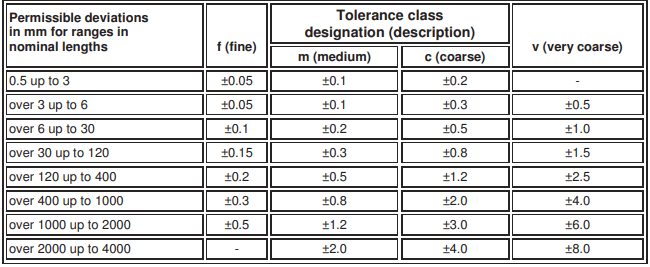

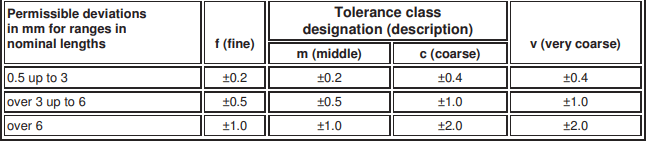

General Tolerance / According to the Drawings requirements

First Class Series Production Service in China

We provide high-quality series production solutions to support your product development and go to the market needs with CNC Machining, Sheet Metal Fabrication, Urethane Casting, and 3D printing technologies. Proto MFG’s manufacturing solutions will give you Stable, committed, on-time, quality, and smooth communication to create, test and refine in ways you never thought possible so you can go to market faster.

1. Fast Turnaround & Affordable

2. DFM feedback to optimize your designs

3. Quick pricing within 4-24 hours

4. On-demand production updates regularly

5. Material certifications & certificates of conformity

6. Free dimensional inspection reports

7. Tight tolerances

8. Sign and follow the NDA