Save time,cost-effectively,free injection molding quotes.

STEP Ι STP Ι SLDPRT Ι IPT Ι PRT Ι SAT files

Plastic Injection Molding

PROTO MFG’s plastic injection molding process offers many advantages over other manufacturing processes. From fast and efficient production to the customization opportunities and increased strength and durability of the parts, plastic injection molding offers companies an ideal choice for manufacturing plastic parts. PROTO MFG is committed to providing high-quality services and products that meet the exact specifications of each project. Their experienced team, state-of-the-art equipment, and innovative technologies, including scientific molding techniques, make them a go-to partner for many companies. Contact PROTO MFG today to learn how their plastic injection molding services can benefit your next project.

Why Choose PROTO MFG’s Plastic Injection Molding

1. Fast and Efficient Production

One of the biggest advantages of PROTO MFG’s plastic injection molding process is its speed and efficiency. Injection molding can create parts quickly and easily, making it an ideal choice for high-volume production runs. Furthermore, since the process is highly automated, it requires less manpower and results in fewer errors or defects. This fast and efficient production process results in lower production costs, faster turnaround times, and higher quality standards.

2. High Precision and Tight Tolerance

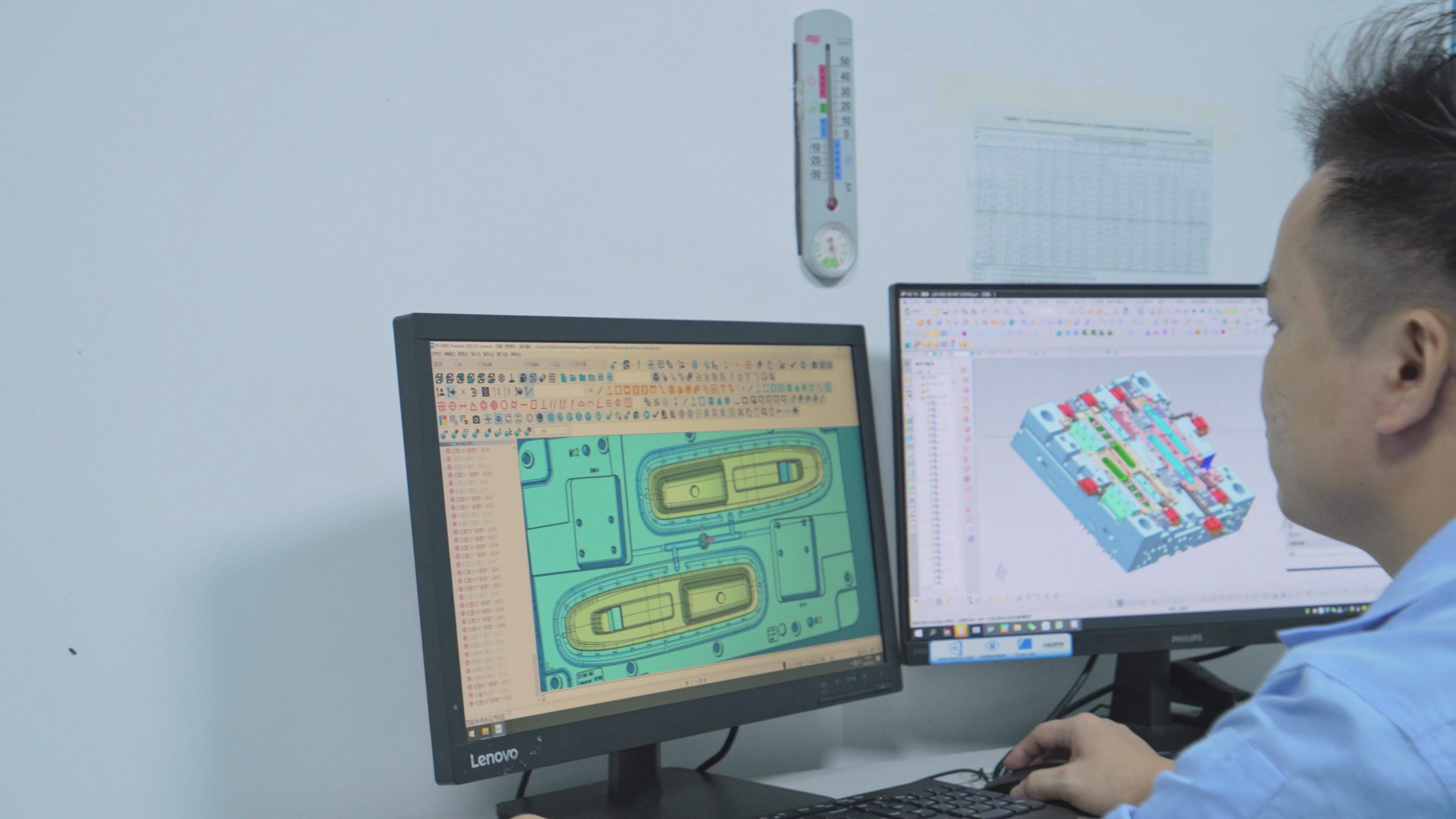

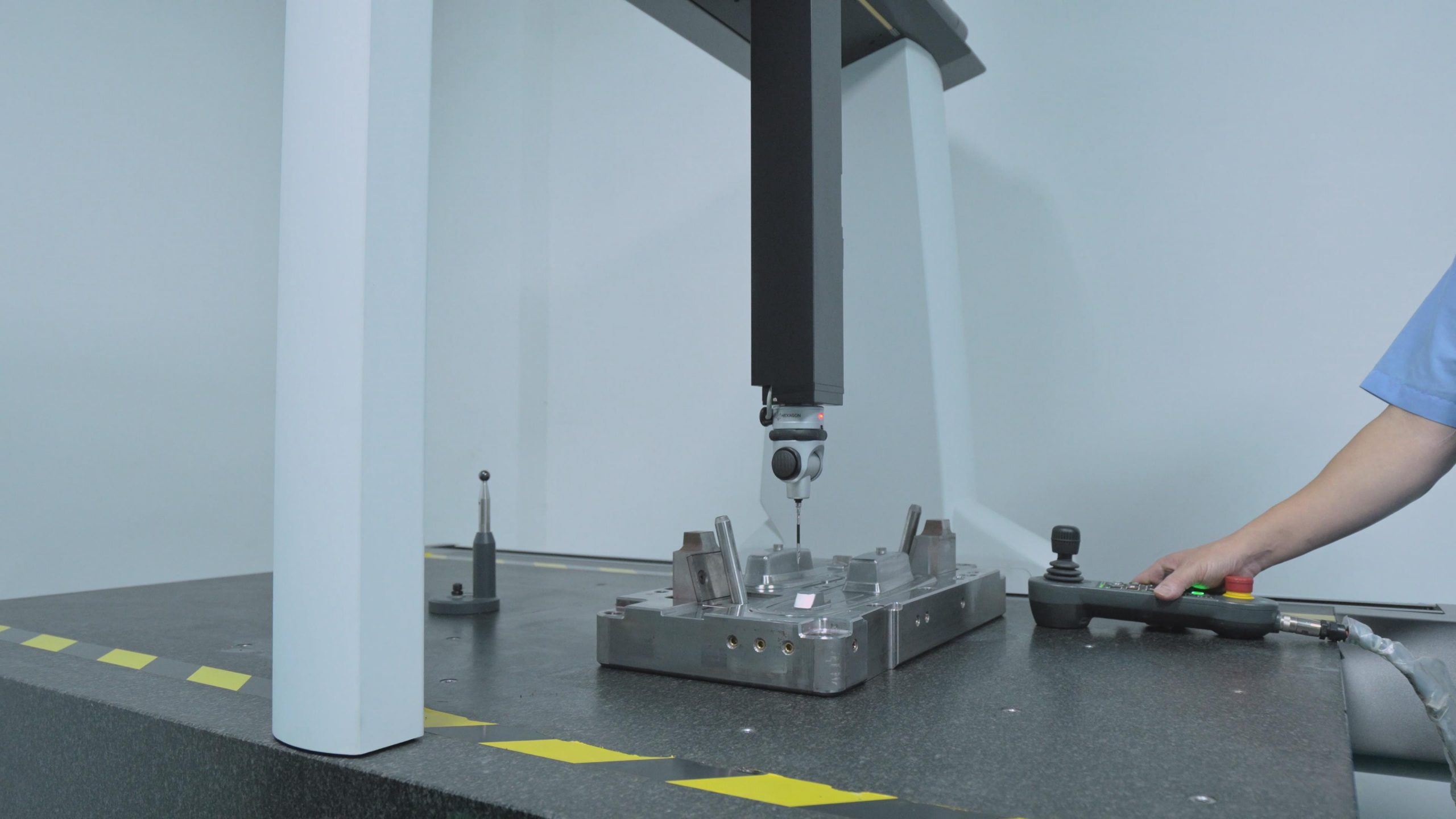

Another significant advantage of plastic injection molding is the high precision it can offer. Injected plastic parts can be highly detailed and complex, with tight tolerances for a perfect fit or function. PROTO MFG uses state-of-the-art equipment and processes to ensure the highest level of accuracy and precision for all parts. The tight tolerances in plastic injection molding give engineers the flexibility and precision necessary to product parts with exacting specifications.

3. Versatility and Customization

With plastic injection molding, PROTO MFG can produce a wide range of parts with varying sizes, shapes, and complexities, resulting in endless possibilities and customization. This versatility is highly beneficial for engineers and designers in need of custom parts that must perform in specific conditions or environments. Furthermore, PROTO MFG provides options for multiple materials, including thermoplastics, thermosets, and elastomers, which allows for high customization opportunities for each project.

4. Increased Strength and Durability

Plastic injection molded parts from PROTO MFG have increased strength and durability compared to other plastic manufacturing processes. The injection molding process compacts the plastic material and distributes it uniformly throughout the part, creating a stronger structure. Depending on the material, the parts produced can withstand intense temperatures, pressure, and wear and tear, making them ideal for a variety of applications.

5. Environmentally Friendly

PROTO MFG’s plastic injection molding process is environmentally friendly due to the minimal scrap or waste produced. The process uses exact quantities of plastic, minimizing the waste material that will either end up in landfill sites or discarded in the recycling system. This is essential for companies that value sustainability and want to reduce their environmental impact.

The Best Plastic Injection Molding Service In China

We provide high-quality plastic parts production solutions to support your product development and go to the market needs with plastic injection molding technologies. Proto MFG’s manufacturing solutions will give you Stable, committed, on-time, quality, and smooth communication to create, test and refine in ways you never thought possible so you can go to market faster.

1. Fast Turnaround & Affordable

2. DFM feedback to optimize your designs

3. Quick pricing within 4-24 hours

4. On-demand production updates regularly

5. Material certifications & certificates of conformity

6. Free dimensional inspection reports

7. Tight tolerances

8. Sign and follow the NDA

Tips for Designing Successful Plastic Injection Molding Parts

1. Material Selection:

Choosing the right material for your plastic injection molding parts is crucial. The properties of each plastic polymer type differ, and it is essential to select a material that aligns with the part’s intended use and functionality. Factors to consider include temperature resistance, mechanical properties, UV resistance, and chemical resistance.

2. Part Geometry:

The geometry of a part offers a range of opportunities for creative design, but it also impacts manufacturing. While some designs may seem perfect on paper, they might not be feasible in practice. Before going ahead with any design, ensure that you consider the impact of the part’s geometry on the molding process, including parting lines, undercuts, and radii.

3. Wall Thickness:

The thickness of each section of a part can impact the processing time and overall quality of the plastic injection molding. Thin sections cool quicker than thick sections, and this can result in internal stresses that can lead to part failure. Ensure the wall thickness is as consistent as possible, and thick enough to provide the necessary mechanical strength without being too thick.

4. Consider Drafts:

Drafts are design features that remove the part from the mold after processing. It is usually a slight tapering of the part to facilitate removal. To avoid mold damage, ensure that you provide adequate draft angles and proper radii.

5. Use Simulation Tools:

The use of simulation software can significantly impact the success of your plastic injection molding design. Simulation tools go beyond visual and physical inspections, providing detailed information regarding the design, process variables, and other relevant factors that inform final decisions.