![]()

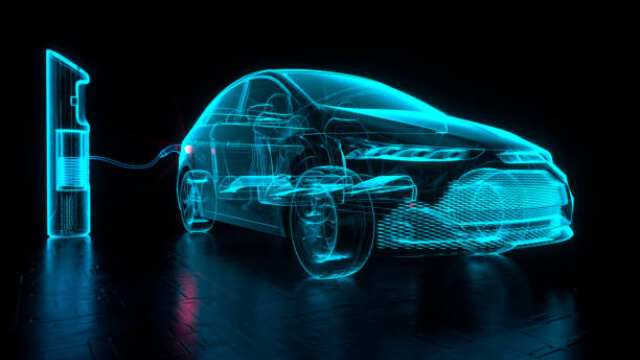

CNC machining helps the automotive industry produce precision parts with high efficiency and speed. This includes producing parts for the drive axle mechanism such as hypoid gears and bevel gears, as well as various shaft and gear components in the gearbox. CNC machining can also be used for electric vehicle manufacturing, which is predicted to be 25% of global vehicle manufacturing by 2030. Additionally, CNC machining offers many advantages over traditional machining including faster production times, increased precision, and better efficiency.