Hardcoat anodizing, also known as Type III anodizing, is an electrochemical process that

creates a thick and durable oxide layer on aluminum surfaces, providing exceptional wear and corrosion resistance properties.

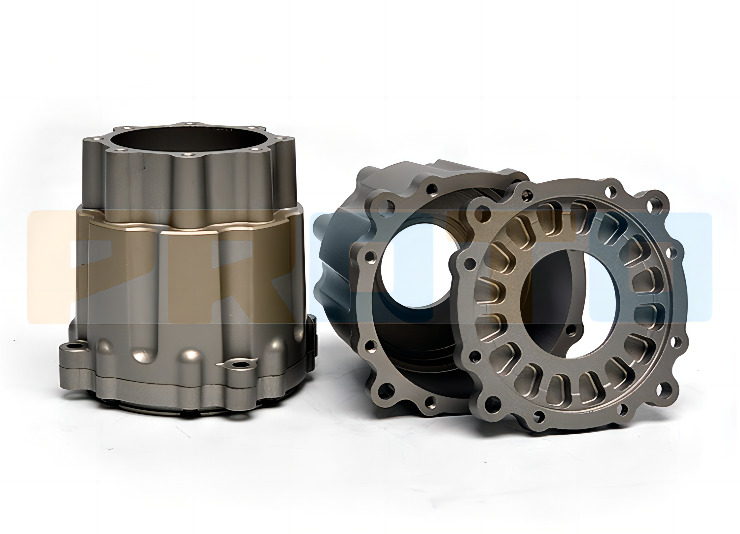

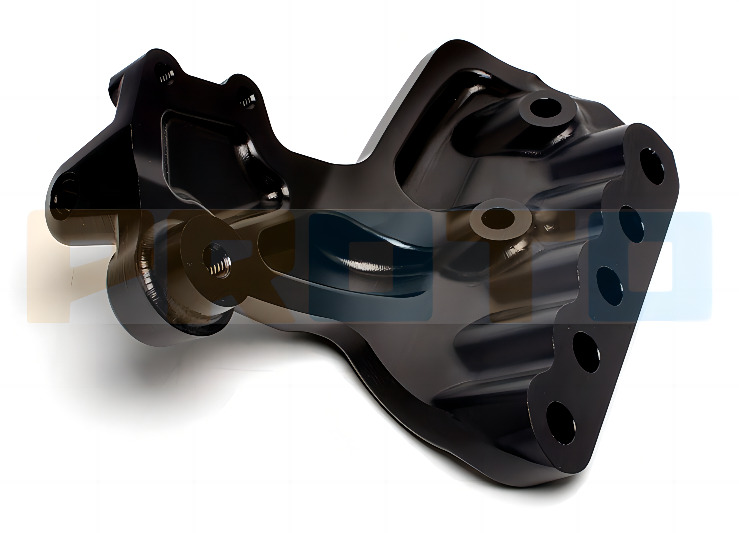

Hardcoat anodizing, also known as Type III anodizing, is widely used in various industries due to its superior surface hardness, abrasion resistance, and corrosion resistance. Some examples of industries and applications that make use of hardcoat anodizing include military, medical, aerospace, automotive, electronics, food manufacturing, housing, machinery, petrochemical, and robotics. In the military, hardcoat anodizing is often applied to firearms, aircraft parts, and other equipment to improve their durability and performance. In the medical industry, hardcoat anodizing is used for surgical instruments, medical implants, and other medical devices. In the aerospace industry, hardcoat anodizing is applied to parts like landing gear, hydraulic systems, and structural components. In the automotive industry, hardcoat anodizing is applied to pistons, cylinders, and other engine components to enhance their wear resistance and durability.