PROTO MFG officially passed the ISO9001 quality management system certification in 2012, which further strengthened the quality management process operation. In order to ensure machined parts quality, we set up incoming material inspection (IQC) and process CMM system (IPQC first article inspection) at the front end of quality. , process inspection, and a final inspection).

No defective production, no defective delivery, and no defective outflow is our attitude toward quality. In the process of process flow, we conduct process inspection (FQC) on different batches of products produced by the same process and the same machine to prevent Unqualified products flow into the next process.

In the finished product inspection link, we set up OQC to inspect the products in all aspects and inspect the appearance, size, and function of the products one by one to ensure that the products in the warehouse meet the drawing standards. In the shipping link, we set up QA to check the shipment The products are inspected and confirmed to ensure that the shipped products meet customer requirements.

Quality Assurance

In the early stage of product quality planning, we have a quality engineering team to carry out corresponding quality planning for the product realization process, formulate SIP inspection specifications, and regularly check gauges and instruments to ensure that testing equipment meets product testing requirements during production.

In the process of product manufacturing, we strictly implement engineering drawing standards and SIP inspection specifications, implement quality inspection operations on products in the process, record inspection data throughout the process, and correspond to product numbers one by one to ensure that the products produced meet your requirements

For the unqualified products produced during the manufacturing process, we dispose of the products in accordance with the “Unqualified Product Control Procedures”, isolate the unqualified products, and scrap them;

In the finished product inspection process, we carry out shipment inspection on the products with reference to the customer’s original drawings, strictly implement the customer’s inspection standards, and ensure that the inspected materials meet the customer’s drawing standards and use requirements.

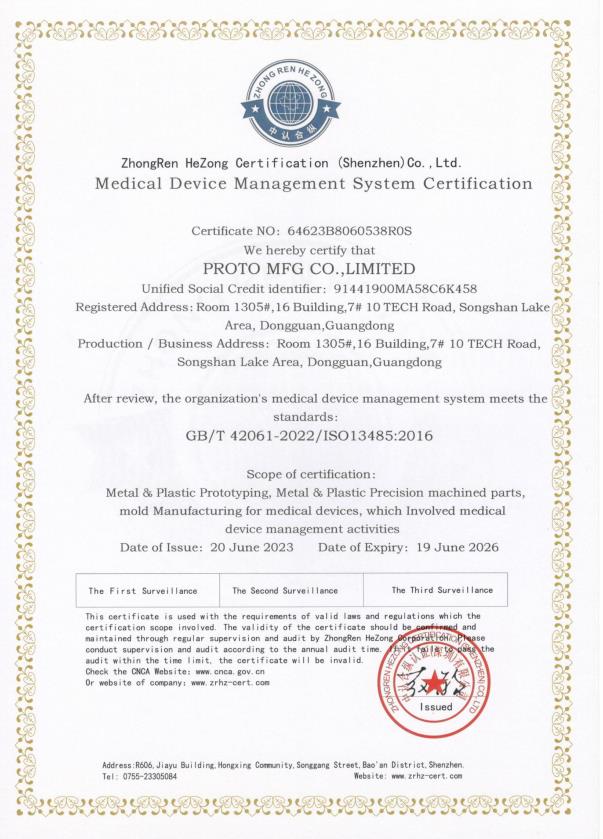

PROTO MFG, a leading manufacturer of precision medical components, recently announced that they have been awarded ISO 13485 certification. But what does this certification mean? And how does it benefit the company’s clients, which include mechanical engineers, buyers, and designers? In this blog post, we’ll take a deep dive into PROTO MFG’s ISO 13485 certification, exploring everything you need to know about this important quality management standard.

First, let’s start with a brief overview of ISO 13485. This internationally recognized standard sets out the requirements for a quality management system (QMS) for medical devices, including components and services. To achieve certification, a company must demonstrate that they meet these requirements and can consistently provide medical devices that meet customer and regulatory requirements.

For PROTO MFG, achieving ISO 13485 certification is a significant achievement. It underscores the company’s commitment to quality and continuous improvement, as well as their ability to meet the unique needs of their medical device customers. In particular, the certification process requires companies to have robust documentation and traceability systems, which can be vital for ensuring patient safety and regulatory compliance.

So, how does PROTO MFG’s ISO 13485 certification benefit their clients? For one, it gives them peace of mind that they are working with a reputable and reliable supplier. ISO 13485 certification is a mark of quality, and it can be a deciding factor in choosing between suppliers. Additionally, it means that PROTO MFG has rigorous quality control and risk management procedures in place, which can help prevent costly recalls and product failures down the line.

Another benefit of working with an ISO 13485-certified supplier like PROTO MFG is the degree of customization and flexibility they can offer. The standard requires companies to be able to adapt to changing customer and regulatory requirements, which can be especially important in the fast-moving world of medical device manufacturing. By working with a customizable supplier, mechanical engineers, buyers and designers can potentially gain more control over their manufacturing process.

Finally, working with a supplier that is ISO 13485 certified can help companies streamline their own regulatory compliance efforts. Medical device manufacturers must adhere to strict regulations in order to maintain their certification, and partnering with a supplier that already meets these standards can potentially make the process smoother and easier.

Overall, PROTO MFG’s achievement of ISO 13485 certification is a positive development for the company and its clients. By demonstrating their commitment to quality and continuous improvement, they are well-positioned to meet the unique needs of the medical device industry. So, whether you’re a mechanical engineer, buyer, or designer looking for a reliable supplier of precision medical components, PROTO MFG’s ISO 13485 certification is a key factor to consider.