Sheet metal (usually steel or aluminum) plays an important role in construction and manufacturing. In the construction industry, it is used as buildings and shells or roofs; in manufacturing, sheet metal is used in auto parts, heavy machinery, etc. When manufacturing sheet metal parts, manufacturers often use the following forming processes.

Crimping

Hemming is a sheet metal forming process. Sheet metal usually has sharp edges with “burrs” after initial production. The purpose of hemming is to smooth the sharp and rough sheet metal edges to meet the needs of the project.

Bend

Bending is another common sheet metal forming process. Manufacturers typically bend metal using a brake press or similar mechanical press. The sheet metal is placed on a die and a punch is pressed down onto the sheet metal. The intense pressure causes the sheet metal to bend.

Ironing

Sheet metal can also be ironed to obtain an even thickness. For example, many beverage cans are made of aluminum, and the aluminum metal sheet is too thick for the beverage can in its original state, so it needs to be ironed to make it thinner and more uniform.

Laser cutting

Laser cutting has become an increasingly common sheet metal forming process. The sheet metal is exposed to a high-power, high-density laser, and the heat of the laser melts or vaporizes the sheet metal in contact with it, forming a cutting process. This is a faster, more precise cutting method that is performed automatically using a computer numerical control (CNC) laser cutting machine.

Stamping

Stamping is a common sheet metal forming process that uses a stamping machine and a die set to punch holes in the sheet metal. During processing, the sheet metal is placed between the punch and the die, and then the punch is pressed down and through the metal plate, thus completing the punching process.

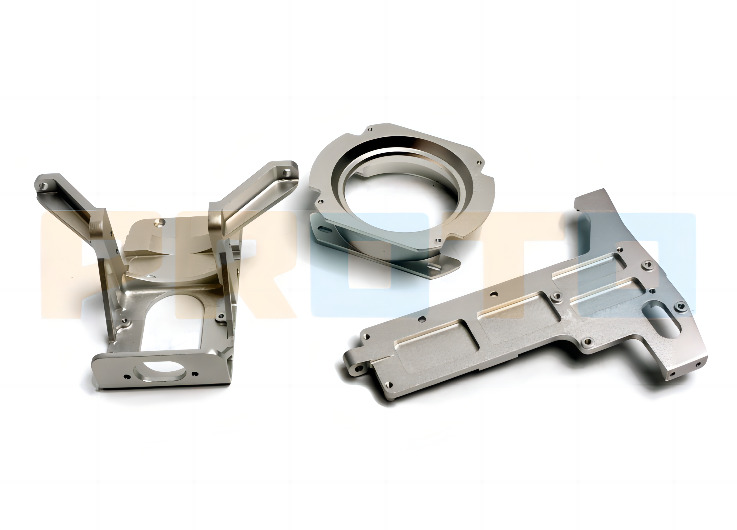

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.