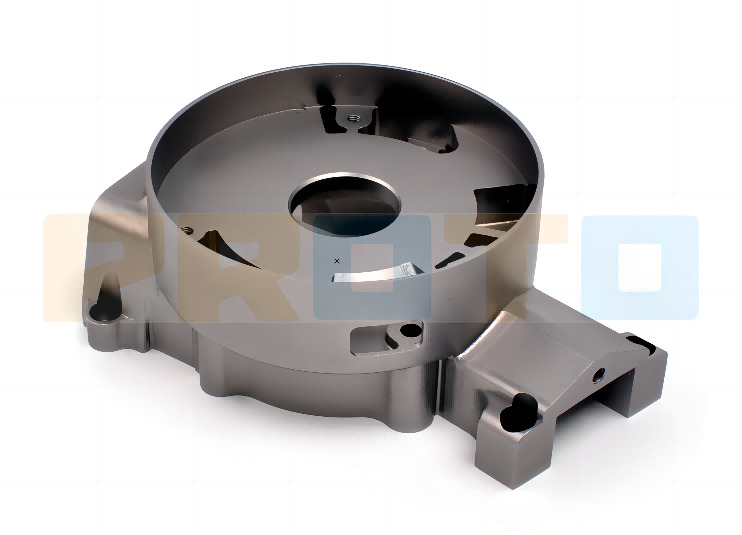

Proto MFG offers a wide range of finishing options for our customer’s custom-made parts, including anodizing, metal plating, and powder coating, to name a few. Abrasive media blasting is a cost-effective way to prepare the surface of your part or alter the cosmetic appearance. This article will walk through one of our most common media blasting finishes; bead blasting. You will learn what bead blasting is, what sort of applications it is used for, and get tips on how to get the most out of the process.

What is Bead Blasting?

Bead blasting is a type of abrasive blasting process in which media is projected onto a surface. The process is often performed using abrasive blast cabinets, which typically use compressed air to accelerate the media. They also provide an enclosed space for the operator to work up close with parts and help avoid spreading dust or contaminants into the air.

Round glass beads are widely used for bead blasting,Unlike other types of media blasting, which typically use angular-shaped media, bead blasting is associated with the use of spherical-shaped media. When a piece of rounded media impacts a part’s surface, it produces a tiny dimple at the impact location. As the process continues, thousands of these dimples consistently form over the surface. When using finer grades, the blasted surface will appear bright with a matte or satin-like texture due to how light reflects off the dimpled surface. Coarser beads can be used to produce a rougher but uniform surface.

What Materials are Used for Bead Blasting?

Glass Bead

Glass beads are one of the most commonly used media types for the bead blasting process. They are usually made from a type of lead-free, soda-lime glass which is environmentally friendly as it does not contain free silica and is chemically inert. When used appropriately, glass bead media is quite durable and can often be re-used up to 30 times. This type of media will not colorize the surface on impact and thus help maintain the material’s base color.

While versatile for many applications, glass bead may not be as suitable for extremely tough materials and is ineffective at etching the surface for paint preparation. This type of media is ideal for surface cleaning, semi-polishing, or peening applications.

Steel Shot

Steel shot is another type of media that can be used. It is made by casting small steel beads according to SAE standard sizes ranging from S-70 (~0.125mm screen size) to S930 (~3mm screen size). There are also multiple hardness ranges, which go from a hardness of 40 Rc up to 62 Rc. The hardness and density of steel shot make it highly durable and in many cases enable it to be re-used for hundreds of cycles! The most common uses for this type of media are cleaning, de-rusting, stripping, and shot peening applications. Metal surfaces can be stress-relieved and hardened to prevent metal fatigue when shot peened using steel shot media.

Steel shot is best used for heavy-duty applications and materials such as steel and cast iron; it is not generally suitable for softer metals or plastics.

Aluminum Oxide

Aluminum Oxide is a tough and abrasive grit media with an angular shape and is often used as a substitute in the sand blasting process. Due to its hardness and angular shape, it is effective at quickly cutting into and etching even the hardest materials. It is often used to prepare surfaces for paint, round sharp edges, and provide a consistent-looking finish. The roughness of the finish will generally correlate to the grit size used. Larger-sized grit will etch the surface more quickly and leave a rougher finish, while finer grits will leave a smoother finish with longer processing times.

Surfaces blasted with aluminum oxide will attain a consistent matte finish with a dull appearance. Aluminum oxide is generally brown in color and can cause some discoloration. Aluminum oxide can be used prior to anodizing to produce uniformly matte anodized parts. It is not suitable for applying finishes to plastic parts.

Plastic Media

While there are multiple types of plastic blasting media, the most common and widely used is called Urea. It is made of angular-shaped grains of recycled plastic materials. Being plastic, it is much more gentle than most other abrasives, highly re-usable, and lightweight. This makes it ideal for use on delicate parts or materials without causing damage. Blasting equipment can accelerate the lightweight plastic particles to high velocities, making it effective at quickly stripping light coatings. Plastic blast media is also helpful for de-flashing and deburring operations for molded parts.

While plastic media such as Urea is excellent for cleaning and stripping applications, it is not a good option for achieving cosmetic finishes since the media does not dimple the surface like other types of media.

Bead Blasting vs. Sand Blasting

While both bead blasting and sand blasting are similar in that they are types of media blasting techniques and sometimes share similar purposes, each is distinct with its advantages and disadvantages. To help you better understand the differences and make the right choices for your project, we have outlined some of the critical aspects for each below.

Bead Blasting

In bead blasting, spherical-shaped media usually made of glass is accelerated to high speed towards the work surface. The round shape of the media has a peening effect and creates small dimples on the surface. The dimples act like miniature mirrors that scatter and reflect light towards the viewer, giving the part a bright and uniform satin-like appearance.

Pros

Cons

Sand Blasting

Sand blasting is a more traditional abrasive media blasting technique in which silica sand is propelled under high pressure towards the workpiece. The irregular shape and sharpness of the sand particles can cut into and etch surfaces with ease. Due to high abrasion, sand blasting can be used to shape surfaces, smooth rough surfaces, and remove surface contaminants such as rust or corrosion. While silica sand is still used in some cases, it is being moved away from due to potential health hazards, and other types of abrasive media are now commonly used in its place. Generally, abrasion blasted parts will have a duller appearance than those that are bead blasted.

Pros

Cons

Conclusion

Bead blasting uses spherical shaped media to semi-polish, peen, or apply satin finishes to metal parts amongst other numerous applications, all while maintaining dimensional accuracy. Other abrasives can be used with media blasting to fit your project’s needs. By understanding the differences in the media options and following best practices for specifying requirements, you can achieve consistent results that meet your expectations.

Proto MFG makes it easy to get custom parts with bead blast or other media blasted finishes! Simply upload your files to the Proto MFG Instant Quoting Engine.