CNC model is a product of modern industry, integrating computer-aided design, computer-aided manufacturing, computer numerical control and other advanced technologies. The three-dimensional model formed on the computer is excavated from a whole piece of material. Therefore, modern industry calls it CNC prototype model.

CNC models are faster than rapid prototyping, and their appearance and structure can better reflect design ideas. Moreover, the surface treatment of CNC models is eclectic: polishing, sandblasting, painting, silk screen, special surface treatment, organic glass color and transparent treatment, electroplating, anodizing, etc. The effect is completely comparable to the products produced after mold opening. Therefore, CNC models have long become the mainstream of modern industry.

In the process of new product development and product replacement, making CNC prototype models is an important and indispensable link. Its functions are as follows:

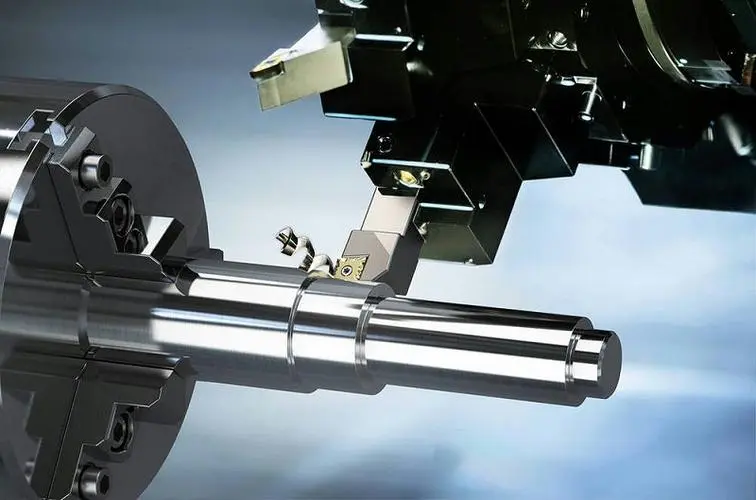

The main features of CNC machining are high precision, short processing time, and the ability to process materials of different substances such as metals.