This article discusses the general properties and applications of two plastics, PMMA and polycarbonate, including CNC machining requirements for acrylic and polycarbonate, and when it is best to use acrylic or polycarbonate in a specific application.

What is PMMA?

Acrylic, or polymethyl methacrylate (PMMA), is a clear thermoplastic commonly used as a replacement for glass. Acrylic is lighter, tougher, and more resistant to UV rays than glass. Acrylic’s optical clarity makes it ideal for lenses, display cases, aquariums, and more.

Acrylic is produced in cast or extruded form, with the cast form being more suitable for processing due to its higher melting point and stiffness, although it costs more. Extruded acrylic is more flexible and better suited for bending or forming operations.

Characteristics of acrylic

Here are some of the key properties of acrylic:

Optical transparency: Acrylic has excellent optical transparency, with a visible light transmittance of up to 92% and a UV light transmittance of 72%. In comparison, glass has a light transmittance of between 80% and 90%.

Chemical Resistance: Acrylic is resistant to a wide range of chemicals, including inorganic acids, fuels, oils and aliphatic hydrocarbons. However, alcohol and organic solvents can damage acrylic parts, causing them to blur, crack, or dissolve.

UV Resistant: Acrylic not only reduces UV transmittance, but is also resistant to long-term UV radiation exposure. Unlike other clear plastics such as PVC or unmodified polycarbonate, acrylic does not yellow when exposed to UV light for extended periods of time, maintaining its optical clarity.

Lightweight: Acrylic is 50% lighter than glass, making it an ideal glass replacement in weight-sensitive applications.

Easy to scratch: Acrylic is not resistant to scratches and is easily damaged, so acrylic panels are often coated with an anti-scratch film. However, this is impractical if the part is CNC machined.

Weak toughness: Acrylic is neither particularly tough nor impact resistant. If toughness is required, polycarbonate or other materials are recommended. When determining the best material to use with acrylic or polycarbonate, the above characteristics should be considered to ensure suitability for the needs of the specific application.

What is polycarbonate?

Polycarbonate is a clear, high-strength engineering thermoplastic commonly used in applications requiring transparency and toughness. Unlike acrylic, polycarbonate can withstand high levels of flexing without cracking.

CNC machined polycarbonate parts, such as eyeglass lenses and diagnostic laboratory equipment, are used in a variety of applications that rely on its clarity and toughness. If you wear glasses, the lenses are most likely made of polycarbonate, not “glass,” as they have been since the 1980s.

Properties of polycarbonate Polycarbonate stands out for its toughness, processability and heat resistance, however, it is affected by UV radiation and has poor scratch resistance.

Here are some of the key properties of polycarbonate:

Optically Clear: Polycarbonate has a light transmittance of up to 90%, slightly lower than acrylic’s 92%, but still slightly better than glass. Polycarbonate also blocks UV radiation.

High Toughness: Polycarbonate is a tough material that is highly resistant to impact loads, capable of absorbing impacts without cracking. Due to its toughness, polycarbonate is used in bulletproof windows.

Fire resistance: Polycarbonate is resistant to flames and will not burn when exposed to an open flame, and the material is self-extinguishing, i.e. polycarbonate will not burn when exposed to an open flame and stops burning when the flame is removed. Specifically, polycarbonate has a flame retardant rating of B1, which means it is “low” flammable.

Contains BPA(s): Some polycarbonate grades contain bisphenol A (BPA) and therefore cannot be used in food containers. Heating polycarbonate will accelerate the release of BPA. This chemical has been linked to a number of adverse health effects, such as cancer and reproductive damage, but BPA-free variants of polycarbonate are also available (such as Tritan).

Poor UV resistance: Polycarbonate is not resistant to UV radiation, so over time the plastic will yellow and the surface will be damaged by UV radiation. UV stabilizers can be added to polycarbonate to prevent yellowing and brittleness due to UV exposure.

Poor scratch resistance: Although polycarbonate is a tough plastic, it is less scratch resistant than acrylic. Therefore, it is often necessary to apply a scratch-resistant coating such as silicon dioxide or titanium dioxide, which can be challenging for geometrically complex parts due to the complex vacuum deposition process.

Processing acrylic and polycarbonate

Knives

When machining acrylic and polycarbonate, it is critical to use sharp cutting tools to limit friction between the tool and the part. A dull drill will cause the plastic to melt due to the heat generated by friction, creating a coating.

Typically, for thermoplastics, tungsten carbide tools are preferred, but polycrystalline diamond (PCD) tools provide the best results. An upcut spiral tool with one or two spiral flutes is often the best tool for milling acrylic and polycarbonate because the tool has a high material removal rate, is very sharp, and does not leave burrs on the machined part. Multi-fluted tools can cause chips to accumulate in holes and grooves and allow material to stick to the cutting tool. For drilling operations, it is best to use a sharp 135-degree drill angle.

Clamping

Both polycarbonate and acrylic can warp if the clamps are too tight because it causes the part to bulge during machining. Once removed from the machine, the material will spring back, causing features to be out of tolerance. However, when mechanical clamping is not ideal, a vacuum table can hold the material in place. Alternatively, double-sided tape can also be used to secure thinner boards to the machine tool, although tape residue may be difficult to remove.

sSpeed and feed

The exact speeds and feeds for processing polycarbonate and acrylic depend on many factors, including machine type, part type and fixtures. However, polycarbonate and acrylic must be cut at high spindle speeds (up to 18,000 RPM), and high feed speeds are also preferred, as slow feed speeds may melt the material.

Polycarbonate has a higher melting temperature than acrylic, so it melts less easily at low speeds and feeds, and sometimes polycarbonate prefers slower feed rates. Acrylic tends to chip more easily, while polycarbonate is tougher and less likely to chip.

Cool down

In most cases, compressed air is sufficient to cool acrylic and polycarbonate parts during processing. However, this highly depends on the speed, feed and type of cutting operation. If immersion or mist cooling is required, use a water-based coolant, as coolants containing organic solvents may damage parts, especially acrylic.

Choice between Acrylic and Polycarbonate CNC Machining

When choosing acrylic vs. polycarbonate for CNC machining, the decision depends on a variety of factors. For example, applications that require increased toughness, higher heat resistance, and good optical clarity are better candidates for polycarbonate. Acrylic is slightly superior in terms of optical transparency, and is more suitable when transparency is the main design factor in applications. Both materials are easy to machine, provided speeds and feeds are relatively high. In some cases, post-processing polishing operations may be required, particularly where optical clarity is required.

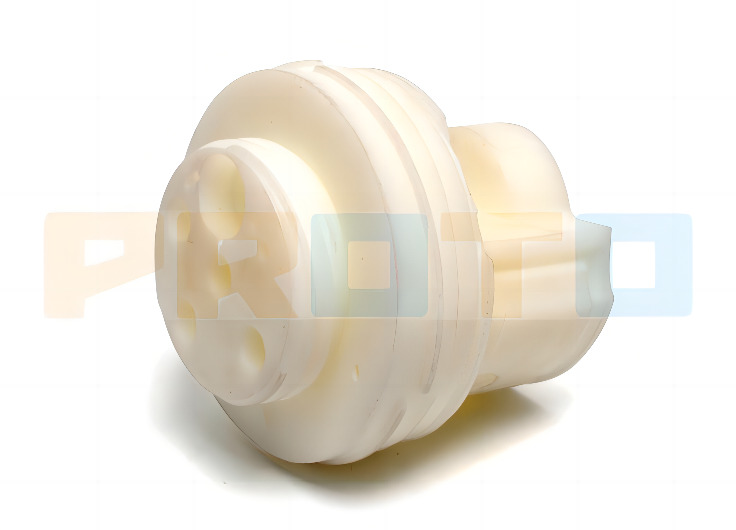

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.