CNC machining is capable of manufacturing complex and precise parts, thanks to its diverse processing techniques, such as milling, turning, drilling, etc. Here, we’ll focus on milling versus drilling to understand their unique capabilities to help you choose the right machining method.

Although you can use any process (or combination) to convert your design into a functional product, which process you use depends on the design specifications and final requirements. So, let’s compare milling and drilling jobs, tool settings, accuracy, advantages, applications, and other aspects.

What is CNC milling?

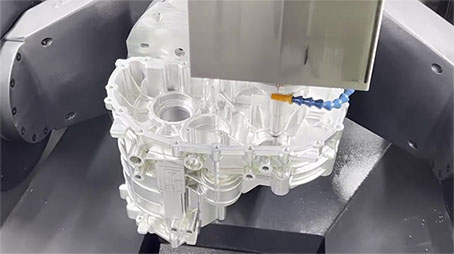

CNC milling is a versatile machining method that uses different rotating cutting tools to precisely cut workpieces into desired shapes. Here, numerical instructions (G and M codes) entered into the CNC milling machine determine the tool movement and removal of material. This controlled automation produces consistent and repeatable parts through digital design.

Due to the multi-axis motion of the tool, milling is suitable for complex designs with fine details. Likewise, it can perform many operations such as cutting, drilling, and engraving. Therefore, milling is suitable for industries that require complex parts with tight tolerances.

What is CNC drilling?

CNC drilling is another subtractive manufacturing method that focuses on creating precise holes in the workpiece based on uploaded CAD designs. It usually involves single-axis motion. Drilling machines utilize a computer-controlled rotating drill bit to drill holes. At the same time, the drill bit size is exactly or slightly smaller than the required hole diameter.

Unlike other operations, the CNC drilling process specializes in drilling holes for different applications. With the corresponding drill bits, you can machine straight holes, center holes, countersunk holes, countersunk holes, tapped holes, reamed holes and other types of holes.

Drilling technology is critical in applications such as electronic components, automotive and aerospace parts, and mechanical assembly.

These two CNC processes are known for their superior machining capabilities in different fields. They all have similar machine settings, precision and control mechanisms. But what is the difference between milling and drilling? Let’s point out the differences in detail and examine the different comparison criteria.

Work process

CNC milling machines convert uploaded CAD designs into computer instructions that determine tool control. Next, secure the workpiece to a vise, clamp, or fixture plate. When the tool (usually an end mill) moves to the initial milling position, the rotating tool begins feeding the material at a predetermined feed rate and speed. At the same time, multi-axis motion allows the tool to move over the workpiece and shape it. Additionally, two different workpiece motions may exist in CNC milling. First, the workpiece moves in the same direction as the tool rotation, which is called down milling or up milling. In the second case, the tool rotates against the feed direction, which is called conventional milling or climb milling. Drilling works by using a rotating drill tool to remove material from the area that needs to be drilled. As with CNC milling, the computer controls the drilling tool. After positioning the workpiece to the drilling coordinates, the drill bit begins to rotate and enter the material (usually along the Z-axis) to create a precise and clean hole.

Movement path

One significant difference between milling and drilling is the motion path of the cutting operation. During operation, the milling tool moves horizontally and vertically moving parts, allowing for more versatile and complex shapes. In contrast, during drilling operations, the attachment moves primarily along a vertical motion path. This is because the focus of drilling is to create a hole or remove material from a specific point.

Tools and settings

Typically, CNC milling involves end mills, face mills, drills or fly knives to machine materials. The right machine tool is necessary for efficient, accurate milling. Drills and end mills are the most common. Therefore, when choosing an end mill versus a drill, you need to consider material type, cutting edge, tool coating, shape and size, and other factors. The workpiece material is then fixed to the machine table and the tool paths are perfectly aligned.

The selection of drill bits for CNC drilling operations depends on the workpiece material, hole depth, size, hardness and finish quality. Additionally, some complex drilling may require custom or specialized tooling. The tool is mounted on the spindle and the workpiece is fixed on the machine tool table.

Accuracy and capability

These are one of the most precise manufacturing processes. They offer high-precision machining with attention to detail. For purposes of illustration, milling produces parts with an accuracy of ±0.005” (0.127 mm), while drilling can achieve tolerances as low as ±0.002” (0.05 mm). Milling can create complex parts or products, from simple slots to complex automotive engine components. Drilling, on the other hand, focuses on forming holes of different shapes and sizes. It can drill holes to a depth of 2600 mm and a diameter of 3–32 mm.

Both processes are compatible with metals, plastics and composite materials. As a result, they can use a variety of materials to meet numerous manufacturing needs.

Commonly used drilling materials

Hardened plastics such as polycarbonate and PEEK

However, milling has more material capabilities than drilling. Drilling and milling are not compatible with hardened tool steels, some ceramics, and some titanium alloys.

Common milling materials

steel

aluminum

brass

Inconel

garnet

Tungsten

Surface finish quality

CNC milling uses multi-axis motion and diverse tooling to achieve versatile machined surface finishes. The roughness value (Ra) of the milled surface can be as low as 1.6µm. Therefore, the Ra value of the drill bit surface can reach 3.48µm. However, the Ra value is affected by cutting depth, material, rotation speed and other factors.

Therefore, milling produces a finer surface finish than drilling due to cutting dynamics. Still, drilling provides a better surface with holes. In addition, milling involves external machining and high-quality machined surfaces can be obtained easily.

Specific industries and applications

Application is probably the most critical aspect of comparison in milling versus drilling, as it determines where these processes are applied. CNC milling can accurately machine any flat surface into any complex angle, such as bends and undercuts.

CNC milling applications

Auto parts, such as cylinder heads, engine blocks, gearbox housings, etc.

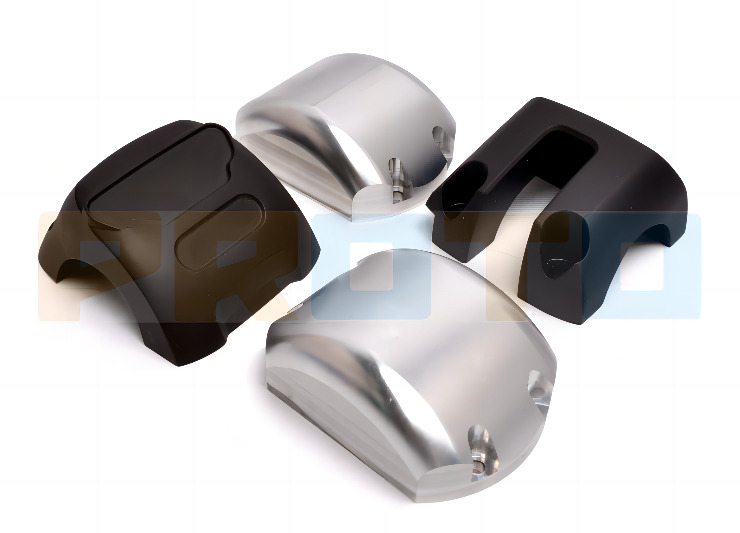

Prototyping for various industries.

Medical device components and implants

Mold and tool manufacturing

CNC milling is preferred over drilling because it can machine detailed geometries. Still, drilling is essential when precise cylindrical features are required.

Application of CNC drilling

Deep and small holes in various materials.

Drill holes for fasteners on aircraft fuselages and engines.

Automobile assembly.

Electronic boards have precise and consistent holes to place components.

Cost considerations

CNC drilling and milling are both cost-effective manufacturing methods. They justify the cost with precision, sophistication and quick turnaround. However, in a head-to-head comparison of drilling versus milling, the CNC milling process is slightly more expensive.

If we break down the cost factors and considerations, milling costs vary based on complexity, workpiece material, machine setup, production speed, and number of operations. At the same time, drilling cost is also affected by drilling depth, hole diameter and number of holes.

Delivery time

Generally speaking, CNC milling has a longer lead time due to the complex machining of the parts. In comparison, lead times for CNC drilling projects are shorter because drilling is a more direct machining focused on hole machining tasks.

However, there are several factors that determine the lead time for any particular milling or drilling project. For example, milling lead time depends on machining complexity, material type, setup time, required accuracy and operator skill. Likewise, drilling lead time is affected by hole count, depth, diameter, and equipment and tool setup time.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.