How to perform surface treatment on sheet metal processing prototype? In order to let everyone know more about the surface treatment process of sheet metal processing, the following will introduce to you the commonly used surface treatment processes of sheet metal prototype processing, such as spraying, electroplating, electrophoresis, anodizing, etc.

There are two types: paint spraying and powder spraying. After the material is pretreated, the paint is sprayed onto the surface of the sheet metal workpiece using a spray gun and gas, and the paint forms a coating on the surface of the workpiece. After high-temperature baking and solidification, it becomes a final coating with different effects.

It is a technology that uses electrolysis to attach a layer of metal mold to the surface of the metal to prevent corrosion, increase wear resistance, conductivity, and provide a high-quality metal appearance. Galvanized, colored zinc, white zinc, blue zinc, black zinc, nickel plating, chrome plating, etc.;

Mainly used in stainless steel, aluminum alloy, etc., it can make the product appear in various colors and maintain the metallic luster, while increasing the surface properties and having good anti-corrosion properties.

Add corresponding surface treatment according to the usage conditions of the part.

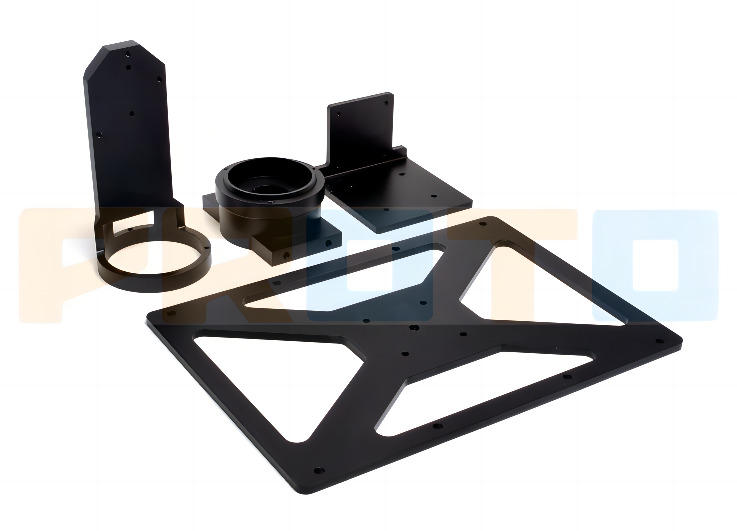

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.