Are you looking for a high-quality and durable compression mold for your manufacturing needs? Look no further than PROTO MFG! With over 10 years of experience in the field, PROTO MFG is a leading provider of custom compression molds that meet the specific needs of your project. In this post, I will provide you with a comprehensive overview and Q&A session about PROTO MFG compression molds, perfect for mechanical engineers, buyers, and designers.

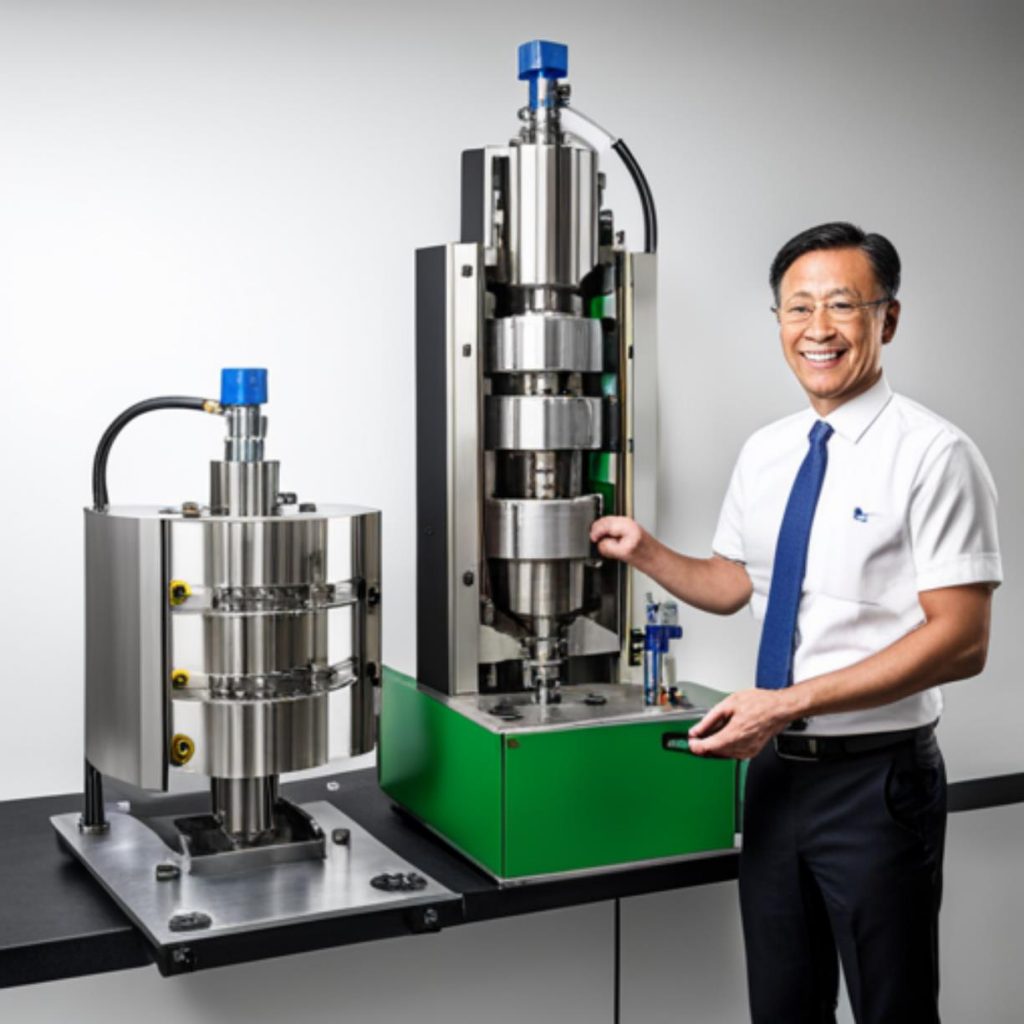

Compression molding is a manufacturing process that involves compressing a specific material, typically a composite, between two mold halves. The mold cavity is heated to cure, shaping the final product. PROTO MFG’s compression molds use high-quality materials, such as stainless steel, to ensure accurate and precise compression during the molding process.

PROTO MFG compression molds offer several benefits, including:

PROTO MFG’s compression molds are suitable for a wide range of industries, including aerospace, automotive, medical, and industrial applications. Depending on your project’s needs, their compression molds can be customized to meet specific requirements, such as specialized materials, shape, and size.

The cost of PROTO MFG compression molds varies depending on several factors, such as the size, material, and complexity of the part you need to produce. In general, PROTO MFG offers competitive pricing in the market, as their molds are durable and long-lasting, ultimately reducing production costs in the long run.

PROTO MFG’s team of experts is available to work with you to design and manufacture a custom compression mold that meets your specific needs. The process typically involves a series of consultations, where they gather information about the part you need to produce and the manufacturing requirements. Afterward, they will create a mold designed to deliver high-quality parts consistently.

Conclusion:

In summary, PROTO MFG’s compression molds are the perfect solution for mechanical engineers, buyers, and designers who need high-quality and precise parts. Their molds offer many benefits, including durability, versatility, and scalability, making them a wise investment for any manufacturing project. So if you are looking for top-quality compression molds, get in touch with PROTO MFG today!