Metal fabrication plays a crucial role in various industries, from manufacturing to construction. Understanding the different methods of metal fabrication can help businesses optimize their production processes and create high-quality products. In this article, we will explore the three main types of metal fabrication techniques and their applications in different industries.

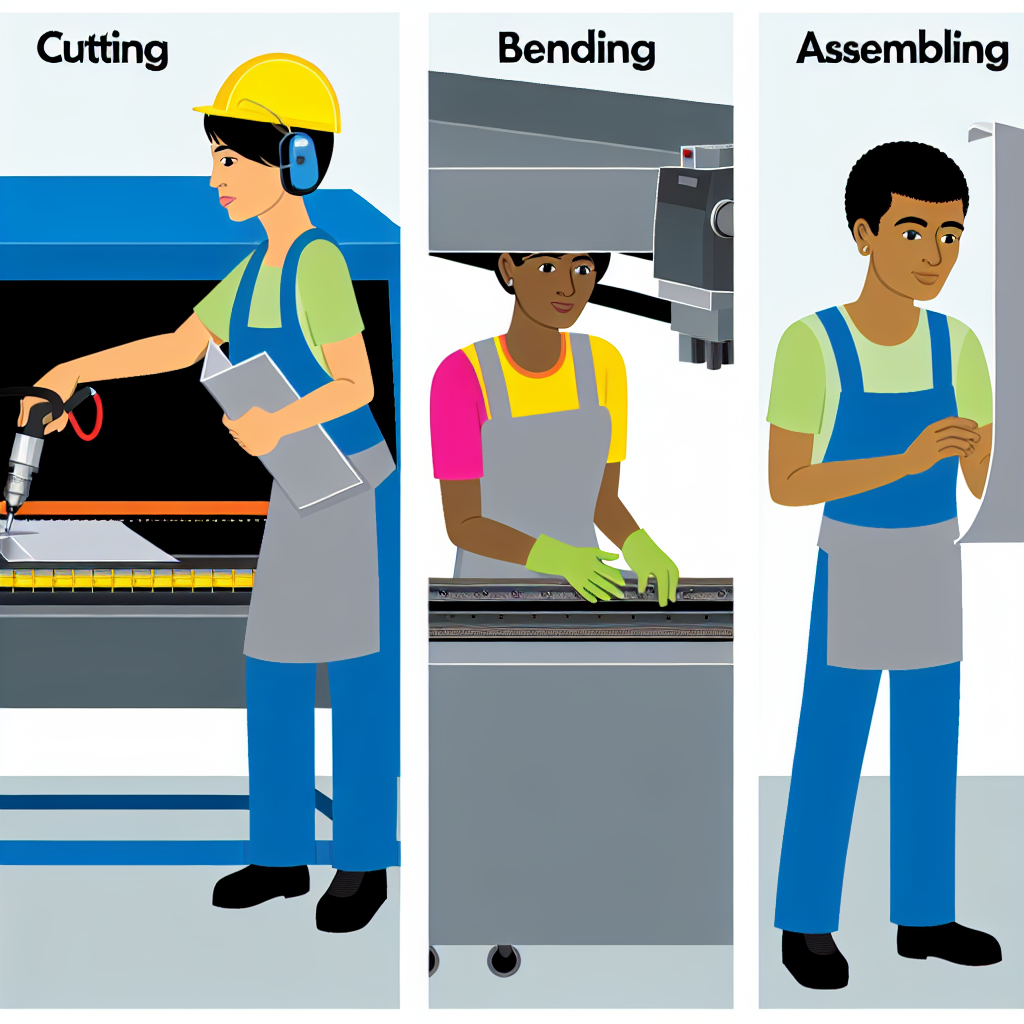

Introduction Metal fabrication is the process of shaping raw metal materials into finished products through a series of techniques such as cutting, bending, welding, and machining. This process is essential in various industries like automotive, aerospace, and construction, where customized metal parts are required for different applications.

Welding is a common metal fabrication technique that involves joining two or more metal pieces together using heat and pressure. There are several types of welding techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. These techniques are used in industries like automotive, construction, and shipbuilding to create strong and durable metal structures.

Machining is another traditional metal fabrication method that involves removing material from a workpiece to create a desired shape or size. Operations like milling, turning, and drilling are used to cut, drill, and shape metal components for various applications. Machining is widely used in industries like aerospace, medical, and electronics for producing precision parts with tight tolerances.

Laser cutting is a modern metal fabrication technique that uses a high-powered laser beam to cut through sheet metal with high precision. This method offers advantages over traditional cutting methods, such as faster cutting speeds, cleaner cuts, and minimal material waste. Industries like automotive, signage, and electronics commonly use laser cutting for producing intricate metal parts.

Bending and forming are essential processes in sheet metal fabrication that involve shaping metal sheets into desired forms. Tools like press brakes, rollers, and dies are used to bend, fold, and stretch metal sheets to create complex shapes. Bending and forming techniques are widely used in manufacturing industries for producing sheet metal components like enclosures, panels, and brackets.

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three-dimensional objects by layering materials like plastic, metal, or composites. In metal fabrication, 3D printing enables complex geometries, rapid prototyping, and customization of parts. Materials like stainless steel, titanium, and aluminum are commonly used in metal 3D printing for various applications in aerospace, medical, and automotive industries.

Sintering is a process of compacting and forming powdered metal materials into solid objects by heating them below their melting point. This method is used in additive manufacturing for creating metal parts with high density, strength, and dimensional accuracy. Sintering has applications in metal fabrication for producing complex components like gears, filters, and medical implants.

In conclusion, metal fabrication encompasses a wide range of techniques and processes that are essential for producing metal components used in various industries.By grasping the three primary metal fabrication methodologies – traditional techniques, sheet metal fabrication methods, and additive manufacturing – enterprises can retain their competitive edge and remain responsive to evolving industry dynamics. With technological progress propelling innovation in metal fabrication, there’s a wealth of career prospects for individuals proficient in metalworking, welding, machining, and additive manufacturing. Keeping abreast of the latest advancements in metal fabrication is essential for staying at the forefront of the sector and capitalizing on the increasing need for bespoke metal goods.