If the materials are wrong, everything is in vain!

There are many materials suitable for CNC processing. To find the material suitable for the product, it is restricted by many factors. A basic principle that needs to be followed is: the performance of the material must meet the technical requirements of the product and the environmental use requirements. When selecting materials for mechanical parts, you can consider the following five aspects.

Material Rigidity

Rigidity is the primary consideration when selecting materials, because products require a certain degree of stability and wear resistance in actual work, and the rigidity of materials determines the feasibility of product design.

According to the characteristics of the industry, 45 steel and aluminum alloy are usually selected for non-standard tooling design; 45 steel and alloy steel are used more for mechanical processing tooling design; aluminum alloy is mostly used for tooling design in the automation industry.

Material stability

For a product with high precision requirements, if it is not stable enough, various deformations will occur after assembly, or it will deform again during use. In short, it will continue to deform with changes in the environment such as temperature, humidity, and vibration. This It’s a nightmare for the product.

Material processing performance

The processing performance of the material means whether the parts are easy to process. Although stainless steel is rust-proof, stainless steel is difficult to process. Its hardness is relatively high, and the tools are prone to wear during processing. When processing small holes in stainless steel, especially threaded holes, it is easy to break the drill bit and the tap, which will lead to very high processing costs.

Anti-rust treatment of materials

Anti-rust treatment is related to the stability of product use and appearance quality. For example, 45 steel usually chooses “blackening” treatment for rust prevention, or parts are spray-painted and plastic-sprayed. Sealing oil or anti-rust liquid can also be used for protection during use according to the requirements of the environment.

There are many anti-rust treatment processes, but if none of the above methods are suitable, the material must be changed, such as stainless steel. In any case, the problem of product rust prevention cannot be ignored.

Material costs

Cost is an important consideration in material selection. Titanium alloys are light in weight, have high specific strength and good corrosion resistance. They are widely used in automobile engine systems and play an immeasurable role in energy saving and consumption reduction.

Although titanium alloy parts have such superior properties, the main reason that prevents titanium alloys from being widely used in the automotive industry is the high cost. If it’s not really needed, choose cheaper materials.

There are many materials suitable for CNC machining. Here are some common materials used for machined parts and their key characteristics:

This is the most commonly used material for CNC machining. It has medium strength, good corrosion resistance, weldability, and good oxidation effect. But aluminum 6061 has poor corrosion resistance when exposed to salt water or other chemicals. It is also not as strong as other aluminum alloys for more demanding applications and is commonly used in automotive parts, bicycle frames, sporting goods, aerospace fixtures, and electrical fixtures.

Aluminum 7075

Aluminum 7075 is one of the strongest aluminum alloys. Unlike 6061, aluminum 7075 has high strength, is easy to process, has good wear resistance, strong corrosion resistance, and good oxidation resistance. It is ideal for high-strength entertainment equipment, automotive and aerospace frames. Ideal.

Brass has the advantages of high strength, hardness, chemical corrosion resistance, easy processing, etc., and has excellent electrical conductivity, thermal conductivity, ductility, and deep drawability. It is often used to manufacture valves, water pipes, air conditioner internal and external machine connecting pipes and Radiators, various complex-shaped stamping products, small hardware, various mechanical and electrical parts, stamping parts and musical instrument parts, etc. There are many types of brass, and as the zinc content increases, its corrosion resistance decreases.

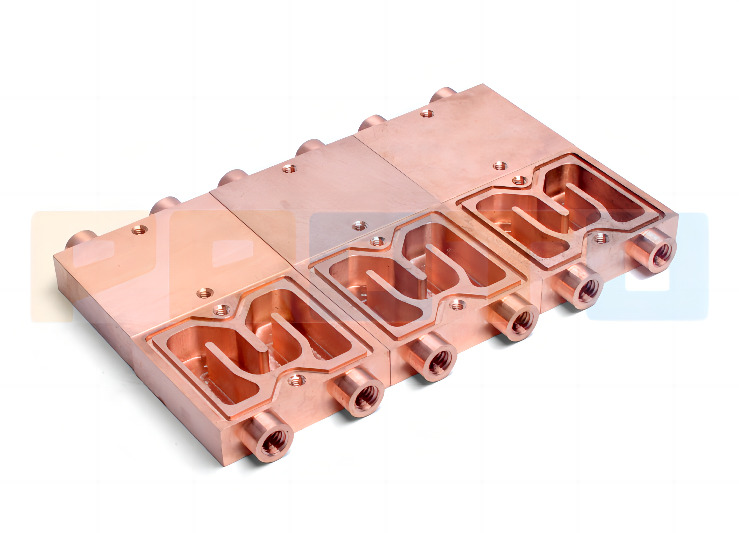

Copper

Pure copper (also known as red copper) has an electrical conductivity and thermal conductivity second only to silver, and is widely used in making electrical and thermal conductive equipment. Copper has good corrosion resistance in the atmosphere, seawater, certain non-oxidizing acids (hydrochloric acid, dilute sulfuric acid), alkali, salt solutions and various organic acids (acetic acid, citric acid), and is often used in the chemical industry.

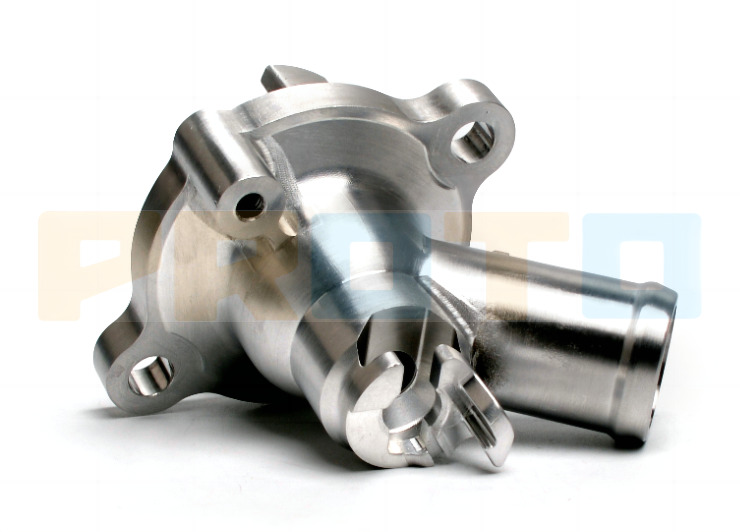

303 stainless steel has good machinability, burn resistance and corrosion resistance, and is used in situations requiring easy cutting and high surface finish. Commonly used in stainless steel nuts and bolts, threaded medical devices, pump and valve parts, etc. However, it should not be used for marine grade accessories.

Stainless steel 304

304 is a versatile stainless steel with good processing performance and high toughness. It is also more resistant to corrosion in most normal (non-chemical) environments, making it an excellent material choice for use in industry, construction, automotive trim, kitchen fittings, water tanks and pipes.

Stainless steel 316

316 has good heat resistance and corrosion resistance, and has good stability in chlorine-containing and non-oxidizing acid environments, so it is generally considered a marine grade stainless steel. It is also tough, easy to weld, and is commonly used in construction and marine fittings, industrial pipes and tanks, and automotive trim.

45 # steel

High-quality carbon structural steel is the most commonly used medium carbon quenched and tempered steel. 45 steel has good comprehensive mechanical properties, low hardenability, and is prone to cracks during water quenching. Mainly used to manufacture high-strength moving parts, such as turbine impellers and compressor pistons. Shafts, gears, racks, worms, etc.

40Cr steel

40Cr steel is one of the most widely used steels in the machinery manufacturing industry. It has good comprehensive mechanical properties, low temperature impact toughness and low notch sensitivity.

After quenching and tempering, it is used to make parts with medium speed and medium load; after quenching and tempering and high-frequency surface quenching, it is used to make parts with high surface hardness and wear resistance; after quenching and medium temperature tempering, it is used to make parts with heavy load and medium speed. Impact parts; after quenching and low-temperature tempering, it is used to manufacture heavy-load, low-impact, and wear-resistant parts; after carbonitriding treatment, it is used to manufacture transmission parts with larger sizes and higher low-temperature impact toughness.

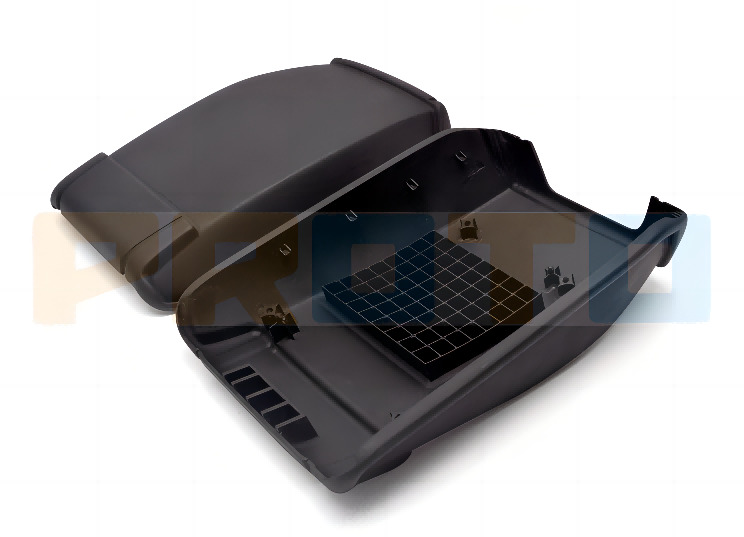

In addition to metal materials, high-precision CNC machining services are also compatible with a variety of plastics. The following are some of the most widely used plastic materials used for CNC machining.

Nylon is wear-resistant, heat-resistant, chemical-resistant, has certain flame retardancy, and is easy to process. It is a good material for plastic replacement of steel, iron, copper and other metals. The most common applications of CNC machined nylon include insulators, bearings, and injection molds.

Another plastic with excellent machinability is PEEK, which offers excellent stability and impact resistance. It is commonly used to manufacture compressor valve plates, piston rings, seals, etc. It can also be processed into internal/external parts of aircraft and many parts of rocket engines. PEEK is the material closest to human bones and can replace metal in manufacturing human bones.

It has excellent impact strength, good dimensional stability, good dyeability, molding and machining, high mechanical strength, high stiffness, low water absorption, good corrosion resistance, simple connection, non-toxic and tasteless, and has excellent chemical properties. It has excellent performance and electrical insulation properties; it can withstand heat without deformation, and it is also a material that is hard, not easily scratched, and not easily deformed.

This article discusses how to select the right materials for CNC machined parts and lists some commonly used materials. If you would like to learn more please contact a PROTO MFG sales representative.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.