Sheet metal fabrication is a versatile and valuable skill that allows individuals to transform flat metal sheets into intricate and functional pieces. From automotive parts to decorative art installations, mastering the art of Sheet metal processing opens up a world of creative possibilities. In this article, we will delve into the history of Sheet metal processing, explore essential techniques and tools, discuss safety precautions, and highlight successful fabricators who have made a mark in the industry. By the end of this article, you will be equipped with the knowledge and inspiration to begin your own sheet metal fabrication journey.

The origins of sheet metal fabrication can be traced back to ancient civilizations, where metalworkers used primitive tools to shape and manipulate metal sheets. Over time, techniques and tools evolved, allowing for more precise and intricate designs to be created. The Industrial Revolution marked a significant turning point in the history of Sheet metal processing, as mass production techniques were developed, leading to the widespread use of sheet metal in various industries.

One of the key benefits of sheet metal fabrication is the durability and longevity of the projects created. Unlike other materials, sheet metal is resistant to corrosion and can withstand harsh environmental conditions, making it ideal for outdoor applications. Additionally, Sheet metal processing offers endless customization and personalization opportunities, allowing individuals to bring their unique visions to life.

To excel in sheet metal fabrication, it is essential to have the right tools at your disposal. Some must-have tools include snips for cutting, a metal brake for bending, and a welder for joining pieces together. Investing in quality tools is crucial for achieving precise and professional results. It is recommended to purchase tools from reputable suppliers to ensure durability and reliability.

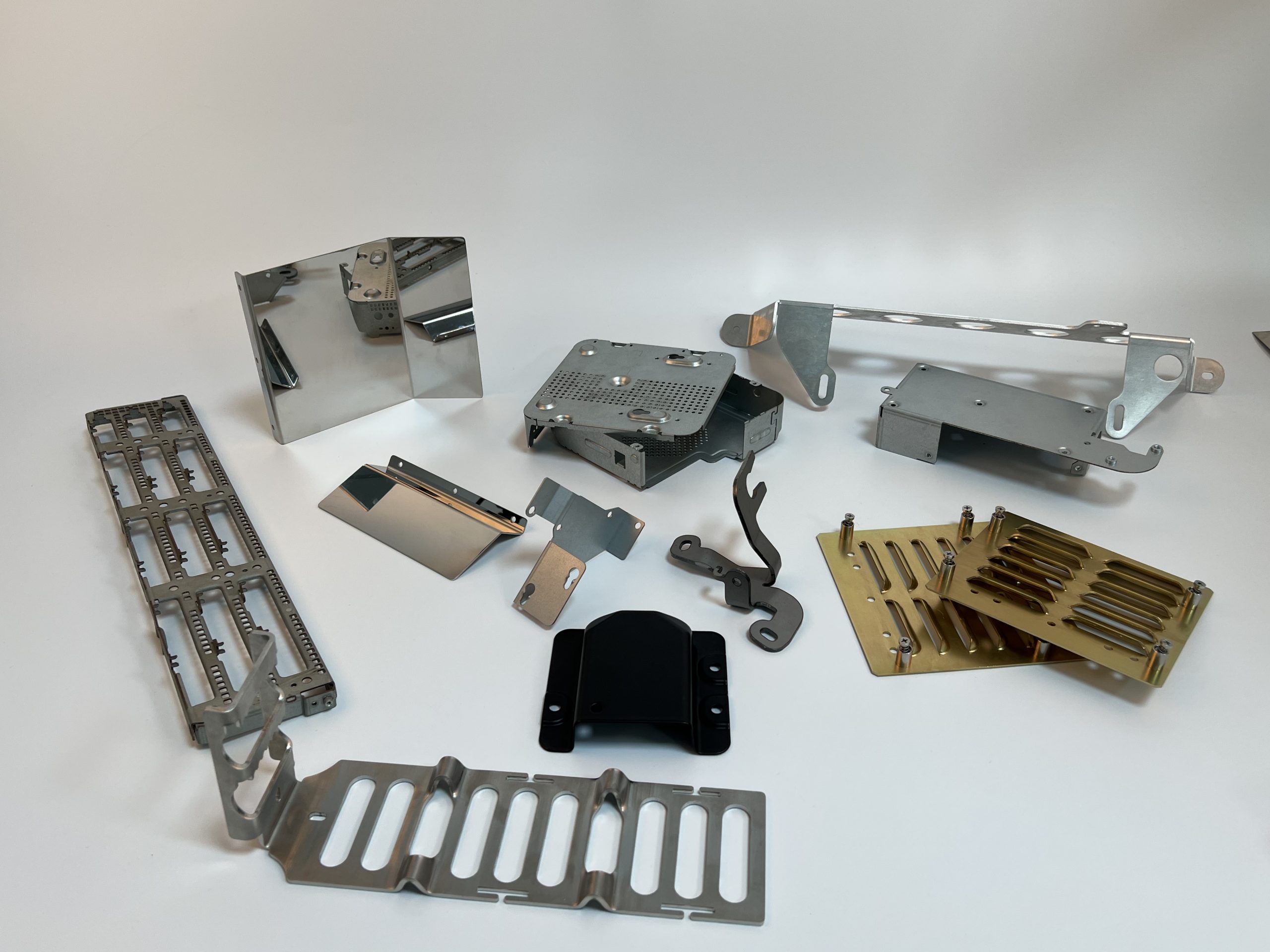

There are various types of sheet metal materials available, each with its own unique properties and characteristics. Common types of sheet metal include aluminum, steel, and copper. The best material for a specific project will depend on factors such as desired finish, strength requirements, and cost considerations. It is important to choose the right material to achieve the desired outcome.

Basic sheet metal fabrication techniques include cutting and shaping methods such as shearing, punching, and drilling. Bending and folding tips are also essential skills to master, as they are used to create folds and creases in the metal. Precision and attention to detail are key when utilizing these techniques to ensure accurate and clean results.

In addition to basic techniques, advanced sheet metal fabrication processes such as welding and soldering are used to join metal pieces together. Welding involves melting metal to bond surfaces together, while soldering uses a lower temperature to create a joint. Finishing touches such as grinding, polishing, and painting are applied to give the final piece a professional look.

Safety should always be a top priority when working with sheet metal. Protective gear such as gloves, safety glasses, and ear protection should be worn at all times to prevent injuries. It is also important to work in a well-ventilated area to avoid exposure to fumes and dust. Following proper safety protocols and being mindful of potential hazards will help ensure a safe and successful fabrication process.

There are several common mistakes that beginners in Sheet metal processing should be aware of. Overheating metal can weaken its structure and cause warping, while incorrect measurements can lead to inaccuracies in the final product. Taking the time to carefully plan and execute each step of the fabrication process will help avoid costly errors.

Finding inspiration for creative sheet metal projects can come from a variety of sources, including nature, architecture, and industrial design. By studying existing creations and experimenting with different techniques, individuals can push the boundaries of traditional Sheet metal processing. Showcase of innovative sheet metal creations can spark ideas and ignite passion for experimentation and creativity.

Joining online communities dedicated to Sheet metal processing provides a platform for sharing knowledge, seeking advice, and collaborating with like-minded individuals. Collaborating with other makers can lead to unique and innovative projects that push the boundaries of traditional fabrication techniques. By networking and collaborating, individuals can gain valuable insights and expand their skills in Sheet metal processing.

Advancements in technology have revolutionized the Sheet metal processing industry, introducing new tools and equipment that streamline the fabrication process. Laser cutting machines, CNC routers, and 3D printing technology have made it easier to create complex and precise designs with ease. As technology continues to evolve, the possibilities for Sheet metal processing are endless.

Profiles of successful fabricators who have made a mark in the industry serve as inspiration for aspiring makers. By learning from their experiences and taking note of their strategies and techniques, individuals can gain valuable insights into the world of Sheet metal processing. Through dedication, hard work, and a passion for the craft, success in Sheet metal processing is attainable for anyone willing to put in the effort.

In conclusion, mastering the art of Sheet metal processing offers endless opportunities for creativity and self-expression. By understanding the history of Sheet metal processing , investing in essential tools, learning basic and advanced techniques, and prioritizing safety, individuals can elevate their projects to new heights. Drawing inspiration from successful fabricators, networking with fellow makers, and staying abreast of technological advancements will further enhance skills and knowledge in sheet metal fabrication. With dedication and a willingness to experiment, the possibilities for creating unique and innovative sheet metal projects are limitless. Start your Sheet metal processing journey today and unlock your full creative potential.