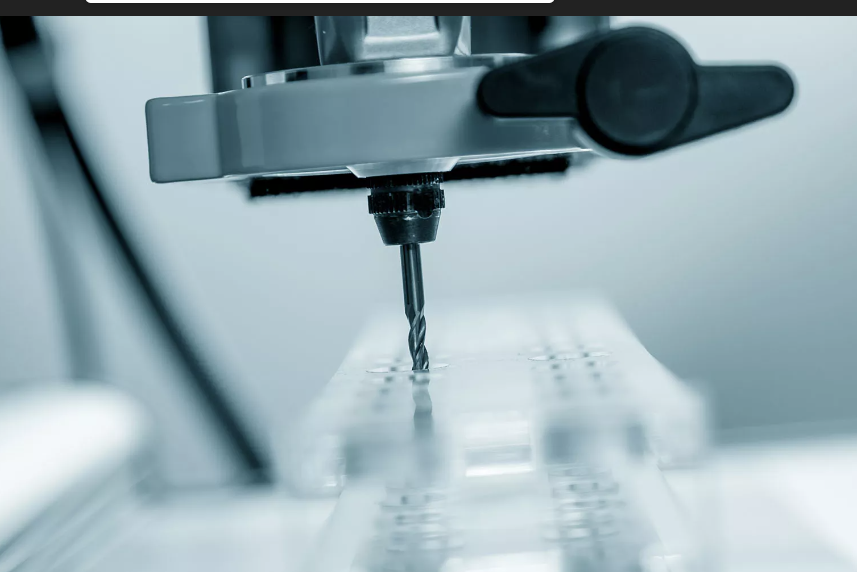

CNC machining has revolutionized the manufacturing industry with its ability to create complex and precise parts with ease. However, to truly master CNC machining, one must understand the importance of CAD/CAM integration. By seamlessly integrating CAD/CAM software into CNC processes, businesses can enhance efficiency and accuracy, ultimately improving their bottom line.

CAD software, short for Computer-Aided Design, is a tool used to create detailed, 3D models of parts or products. This software allows engineers and designers to visualize and simulate their ideas before production begins. On the other hand, CAM software, or Computer-Aided Manufacturing, takes the design created in CAD software and generates the toolpaths necessary for the CNC machine to create the physical part. CAM software plays a crucial role in translating design into reality.

The seamless integration of CAD/CAM software in CNC machining is essential for streamlining the manufacturing process. By connecting the design and manufacturing phases, businesses can eliminate errors and reduce production time. Successful case studies have shown that integrating CAD/CAM software can lead to increased productivity, improved accuracy, and cost savings.

When selecting CAD software, businesses should consider factors such as ease of use, compatibility with other software, and the availability of advanced features like parametric modeling and assembly design. On the other hand, CAM software selection should focus on capabilities such as toolpath optimization, simulation tools, and post-processing options. Compatibility between CAD and CAM software is crucial for seamless integration.

To successfully implement CAD/CAM integration in CNC machining, businesses should provide training and support to employees. Overcoming challenges such as data compatibility and workflow adjustments is key to a smooth transition. Best practices for integration include thorough testing, clear communication between departments, and ongoing evaluation to ensure optimal performance.

Integrated CAD/CAM systems offer a range of benefits for CNC machining operations. By optimizing toolpaths, businesses can increase productivity and reduce machining time. The reduction of errors and material waste is another advantage of CAD/CAM integration, leading to cost savings and improved quality control. Additionally, CAD software enhances design capabilities, allowing for more complex and innovative designs to be realized. Real-time monitoring and control of CNC machines further ensures that production runs smoothly and efficiently.

The future of CAD/CAM integration in CNC machining looks promising, with advances in technology driving innovation in the industry. Integration with IoT and Industry 4.0 will enable real-time data analysis and decision-making, optimizing production processes. Predictive maintenance and machine learning algorithms are set to revolutionize CNC machining by enabling proactive problem-solving and performance optimization. The impact of these advancements on future manufacturing processes is expected to be significant, leading to increased automation and efficiency.

In conclusion, CAD/CAM integration is crucial for businesses looking to master CNC machining and stay ahead in the competitive manufacturing industry. By investing in integrated software solutions, companies can improve efficiency, precision, and overall productivity. It is essential for businesses to recognize the importance of CAD/CAM integration and take action to implement these systems in their manufacturing processes. The future of CNC machining with CAD/CAM integration is bright, and businesses that embrace this technology will undoubtedly reap the benefits of improved performance and profitability.