CNC (Computer Numerical Control) machining has come a long way since its introduction in the 1940s. Originally developed for the aerospace industry, CNC machines have revolutionized the manufacturing industry with their precision and efficiency. Today, CNC machining is used in a wide range of industries, from automotive to medical devices, and is essential for creating complex parts and components with high accuracy.

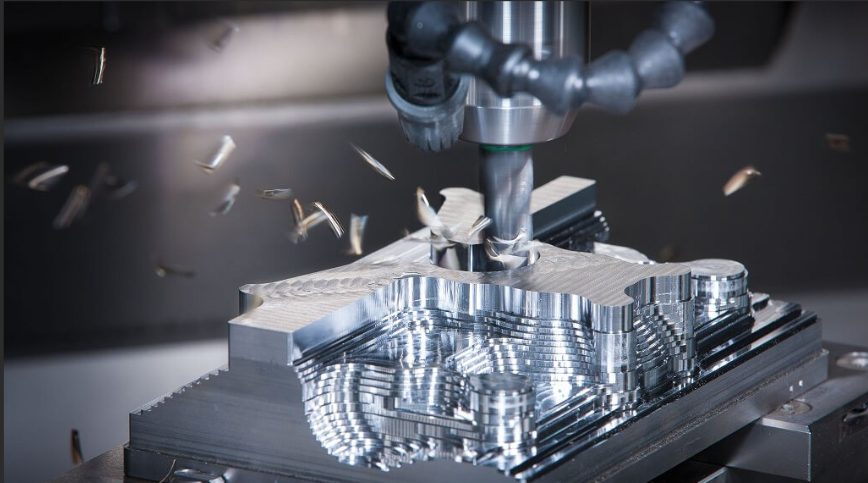

At its core, CNC machining involves using computer-controlled machines to perform various manufacturing tasks. These machines follow pre-programmed instructions to cut, shape, and drill materials with unparalleled precision. Understanding the basics of CNC machining is crucial for mastering this technology and taking your projects to the next level.

When getting started with CNC machining, it’s important to choose the right machine for your projects. There are various types of CNC machines, including milling machines, lathes, and routers, each designed for specific tasks. Consider the size of your projects, the materials you’ll be working with, and your budget when selecting a CNC machine.

In addition to a CNC machine, there are essential tools and equipment you’ll need for successful machining. These include cutting tools, clamps, measuring instruments, and safety gear. Investing in high-quality tools will not only improve the quality of your work but also ensure the safety of your operators.

Creating a well-organized and efficient workspace is key to achieving optimal results with CNC machining. Ensure your workspace is well-lit, properly ventilated, and free from clutter. Organize your tools and materials for easy access, and implement safety protocols to protect yourself and your team.

CNC programming is the process of creating instructions for the CNC machine to follow. There are various programming languages used in CNC machining, including G-code and M-code. Understanding these languages and how they work is essential for writing accurate and efficient CNC programs.

Writing basic CNC programs involves specifying the toolpath, cutting parameters, and material references for the machine to follow. This is typically done using a CNC programming software, where you input the required commands and create a code that the machine can interpret. Pay attention to details and precision when writing CNC programs to avoid errors in production.

To truly master CNC programming, it’s important to explore advanced techniques for optimizing your programs. This includes using macros, subroutines, and loops to streamline repetitive tasks and improve efficiency. By continuously refining your programming skills, you can achieve greater precision and productivity in your machining projects.

There are several popular CNC software programs on the market, each offering unique features and capabilities. Some of the top software programs include Autodesk Fusion 360, Mastercam, and SolidWorks CAM. These programs provide tools for designing parts, creating toolpaths, and simulating machining operations.

When choosing a CNC software program, it’s important to compare different options to find the best fit for your needs. Consider factors such as ease of use, compatibility with your CNC machine, and the range of features available. Some software programs offer advanced simulation capabilities, while others focus on user-friendly interfaces for beginners.

To choose the right CNC software for your needs, consider your specific requirements and goals. If you’re new to CNC machining, opt for software programs with tutorials and user-friendly interfaces. For advanced users, look for programs with advanced toolpath optimization and customization options. Ultimately, the right software can make a significant impact on the quality and efficiency of your machining projects.

To enhance your CNC machining skills, it’s important to continuously learn and explore advanced machining techniques. This includes mastering multi-axis machining, adaptive toolpaths, and high-speed cutting strategies. By pushing the boundaries of your knowledge and skills, you can tackle more complex projects and achieve higher levels of precision.

Even the most experienced machinists encounter issues during CNC machining. From tool breakage to programming errors, troubleshooting common problems is essential for maintaining productivity. Develop a systematic approach to diagnosing and resolving issues, and seek guidance from industry experts or online resources when needed.

Precision is the hallmark of quality in CNC machining. To achieve precise results, focus on fine-tuning your machining processes from start to finish. This includes optimizing cutting parameters, selecting the right tools for the job, and calibrating your machine for accuracy. By paying attention to every detail, you can elevate the quality of your work and deliver exceptional results.

Lean manufacturing principles focus on eliminating waste and improving efficiency in production processes. By applying these principles to CNC machining, you can streamline workflows, reduce lead times, and increase productivity. Implement strategies such as value stream mapping, 5S organization, and continuous improvement to maximize efficiency in your machining operations.

Streamlining production processes is essential for maximizing efficiency with CNC machining. This includes optimizing tool changes, minimizing downtime, and reducing material waste. Develop standardized work procedures, invest in automation technologies, and prioritize training for your operators to create a streamlined and efficient production environment.

Automation is a game-changer in CNC machining, offering increased efficiency and consistency in production. By implementing automated tool changers, robotic loading systems, and machine monitoring software, you can optimize workflow and reduce manual intervention. Embrace automation technologies to enhance productivity and competitiveness in the market.

Artificial intelligence (AI) is revolutionizing the manufacturing industry, including CNC machining. AI algorithms can optimize toolpaths, predict tool wear, and improve machining strategies based on real-time data. By embracing AI technology, machinists can achieve higher levels of precision, efficiency, and cost-effectiveness in their operations.

3D printing technologies are becoming increasingly integrated into CNC machining processes. By combining additive manufacturing with subtractive methods, machinists can create complex geometries, prototypes, and customized parts with ease. Incorporate 3D printing technologies into your machining workflow to expand your capabilities and offer innovative solutions to clients.

The future of CNC machining is full of exciting possibilities, driven by advancements in technology and automation. From IoT-enabled machines to virtual reality simulations, the industry is evolving rapidly to meet the demands of modern manufacturing. Stay ahead of the curve by exploring emerging trends, investing in cutting-edge technologies, and adapting to the changing landscape of CNC machining.

Mastering CNC machining requires a combination of technical knowledge, hands-on experience, and continuous learning. From understanding the basics of CNC machining to exploring advanced techniques and software programs, every aspect plays a crucial role in achieving success. By embracing innovation, maximizing efficiency, and fine-tuning your processes, you can take your CNC machining skills to the next level.

To continue your journey in mastering CNC machining, focus on expanding your knowledge, honing your skills, and staying up-to-date with industry trends. Join online communities, attend workshops and seminars, and collaborate with industry experts to enhance your expertise. With dedication and perseverance, you can unlock the full potential of CNC machining and elevate your projects to new heights.