Proto tooling plays a crucial role in the development of successful prototypes. It is a key component that can make or break the prototype development process. Proto tooling refers to the tools and molds used to create prototypes that closely resemble the final product. These tools are essential for ensuring accuracy, consistency, and efficiency throughout the prototype development phase. In this blog, we will delve into the importance of prototyping in prototype development and provide an overview of what prototyping entails. Join us on this journey to mastering prototyping for successful prototypes.

Understanding Proto Tooling

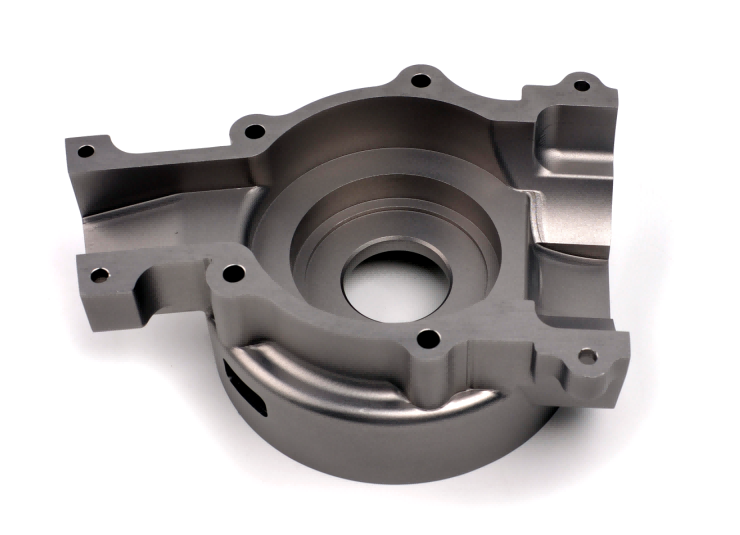

Proto tooling, short for prototype tooling, refers to the specialized tools and equipment used in the process of creating prototypes. These tools are essential in rapidly, accurately, and cost-effectively developing prototypes for various industries.

There are several types of prototyping available, including but not limited to:

Each type of prototyping serves a specific purpose in the prototyping process and understanding their capabilities is crucial for successfully creating prototypes.

When it comes to selecting prototyping for your prototypes, there are several factors to consider. First and foremost, you need to think about the specific requirements of your project, such as the size and complexity of the prototype you are creating. Additionally, you should take into account your budget and timeline, as these factors can impact the type of tooling you are able to use.

In the market, there are several popular prototyping options available. These include 3D printers, CNC machines, and injection molding tools. Each of these options has its own strengths and weaknesses, so it is important to carefully evaluate which one is best suited to your project.

Ultimately, choosing the right prototyping is crucial for the success of your prototypes. By taking the time to consider the factors mentioned above and exploring the various options available, you can ensure that your prototypes are of the highest quality and meet your project requirements.

Incorporating proto tooling in the design process is essential for creating successful prototypes. By considering the capabilities and limitations of prototyping early on, designers can ensure that their designs are feasible for manufacturing. This proactive approach can help to avoid costly revisions later in the process.

When designing prototypes using prototyping, it is important to keep a few tips in mind. Firstly, it is crucial to work closely with your tooling supplier to understand their capabilities and processes. This collaboration can help to optimize your designs for the specific tooling being used.

Additionally, designers should prioritize simplicity and practicality when working with prototyping. By keeping designs straightforward and minimizing unnecessary complexities, prototypes can be produced more efficiently and effectively.

Overall, incorporating proto tooling in the design process and following these tips can lead to successful prototypes that meet both design requirements and manufacturing capabilities.

When it comes to creating successful prototypes, mastering prototyping is essential. Utilizing the right prototyping techniques with prototyping can make a significant difference in the outcome of your project. Common machining processes used with proto tooling include milling, turning, drilling, and grinding. These processes are crucial for shaping and forming the materials needed for your prototype. By understanding and mastering these techniques, you can ensure that your prototypes are accurate, high quality, and successful in achieving their intended purpose.

In conclusion, mastering proto tooling is essential for creating successful prototypes. By carefully selecting the right tools and techniques, designers and engineers can streamline the prototyping process, saving time and resources in the long run.

Key takeaways include:

In final thoughts, it is clear that proto tooling has a significant impact on the success of prototypes. Investing time and resources into mastering these tools can lead to more innovative and high-quality final products. Ultimately, proto tooling is a key factor in turning ideas into reality and bringing successful products to market.