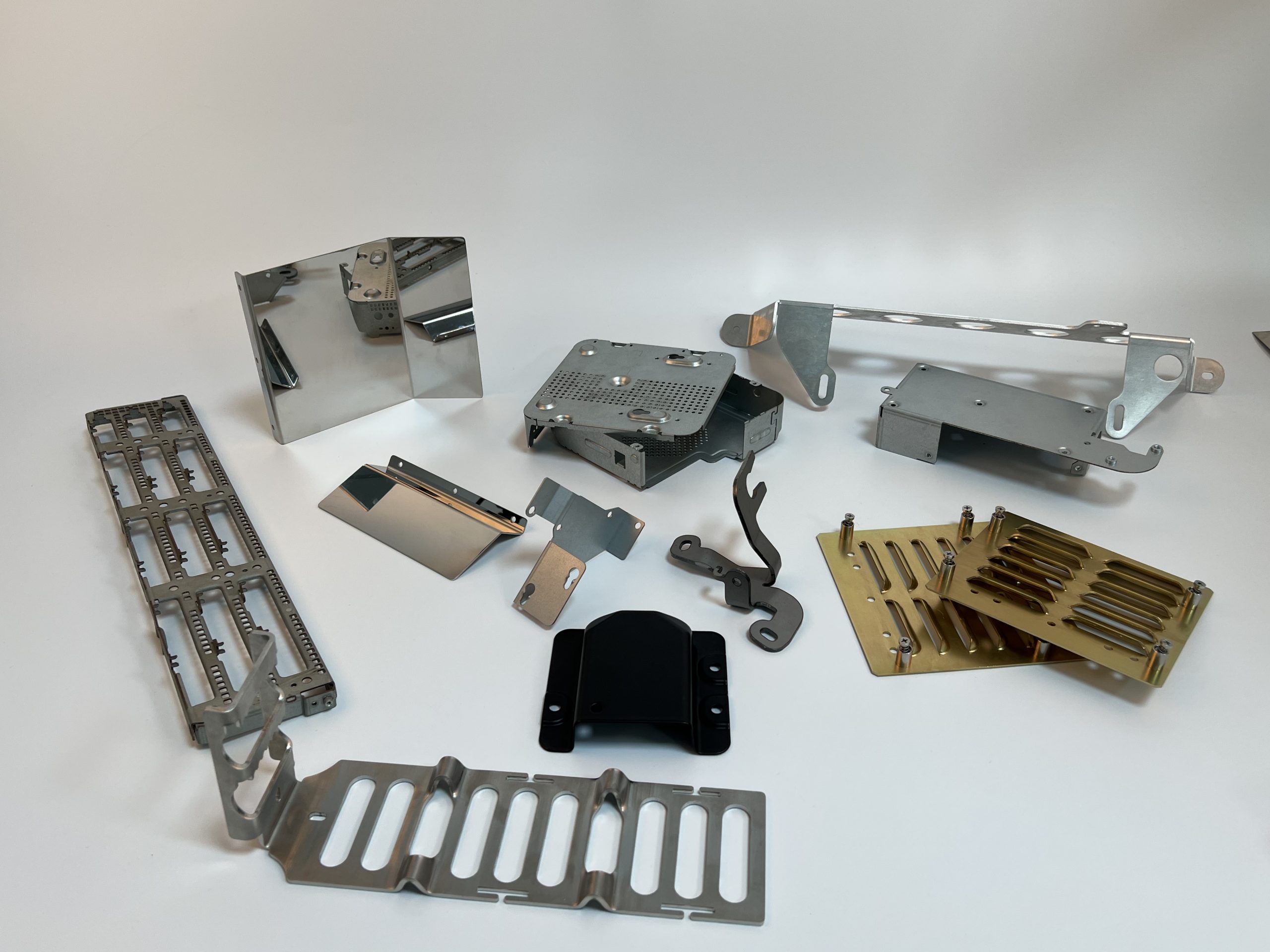

In the world of metalwork, Mastering sheet metal bending techniques can improve your craftsmanship. By understanding the properties of sheet metal, utilizing the right tools and equipment, and honing your bending techniques, you can create precise and high-quality metal components for a variety of projects. Let’s explore the importance of mastering sheet metal bending techniques and how these skills can elevate the quality of your work.

When it comes to sheet metal bending, it’s important to understand the different types of materials available. From aluminum and stainless steel to copper and brass, each material has unique properties that can impact the bending process. Factors such as thickness, ductility, and tensile strength must be considered when selecting the right sheet metal for your project.

To perfectly execute sheet metal bending, you’ll need a variety of tools at your disposal. From simple hand tools like bending brakes and edge rollers to more complex equipment like hydraulic press brakes and CNC machines, having the right tools can make a significant difference in the quality of your bends. Proper maintenance and care of your tools are also essential to ensure consistent results.

V-bending and U-bending are two common techniques used in sheet metal bending. By carefully aligning the metal with the bending tool , you can achieve accurate bends and angles. It’s important to pay attention to details such as bend radius, tooling selection to ensure precise results every time.

For more complex shapes and angles, advanced bending techniques are required. Knowing how to overcome challenges such as springback and wrinkling is crucial. By mastering techniques like air bending and bottoming, you can achieve intricate bends with precision and accuracy.

Bend allowance is a critical factor in sheet metal process, as it determines the flat pattern length required for a bend. By calculating bend allowance accurately, you can ensure that your bends are positioned correctly and meet the desired dimensions. Understanding factors such as material thickness, bend angle, and inside radius is key to producing precise results.

Bend deduction plays a crucial role in sheet metal process, as it compensates for the material lost during the bending process. By accurately determining bend deduction based on material thickness and bend angle, you can avoid errors and ensure that your bends are consistent and uniform. This calculation is essential for achieving perfect results in your metalwork.

Factors Affecting Bending Force The amount of force required for bending is influenced by various factors such as material type, thickness, and bend angle. Adjusting bending force accordingly is important to prevent damage to the material and ensure clean bends. By understanding these factors and making adjustments as needed, you can achieve professional results in your sheet metal bending projects.

Wrinkling and springback are common defects that can occur during the bending process. Identifying these issues early on and implementing strategies to avoid them is key to producing high-quality bends. Techniques such as adjusting tooling, controlling material feed, and using proper lubrication can help prevent and correct bending defects, resulting in superior finished products.

Bending sheet metal in different directions, whether it’s up, down, left, or right, requires skill and precision. By mastering techniques for bending in various orientations, you can create complex shapes and angles with ease. Understanding how to manipulate the material and adjust your tooling for different directions will enable you to achieve seamless bends in any orientation.

Jigs and fixtures play a vital role in sheet metal process, providing support and guidance to ensure accurate and repeatable results. By designing and setting up jigs and fixtures correctly, you can streamline the bending process and increase efficiency in your workflow. The benefits of using jigs and fixtures include improved precision, reduced setup time, and consistency in bend angles.

Finishing processes such as trimming and hemming are essential steps in sheet bending to achieve a polished final product. These secondary operations add a professional touch to your metal components and enhance their appearance and functionality. By incorporating finishing processes into your workflow, you can elevate the quality of your work and deliver superior results to your clients.

Safety is paramount when working with sheet metal , as the process involves high forces and sharp tools that can pose risks if not used correctly. Following best practices such as wearing protective gear, securing workpieces properly, and using machinery safely can prevent injuries and accidents in the workshop. By prioritizing safety, you can ensure a safe and productive working environment for yourself and others.

To truly master sheet metal bending techniques, continuous learning and practice are essential. Expert tips and tricks from seasoned professionals can help you refine your skills and improve the quality of your bends. By experimenting with different materials, techniques, and tooling options, you can expand your knowledge and expertise , setting yourself apart as a skilled artisan in the metalworking industry.

In conclusion, mastering sheet metal bending techniques requires a combination of knowledge, skill, and practice. By understanding sheet metal properties, selecting the right tools, and honing your bending techniques, you can produce high-quality metal components for a wide range of applications. Remember to calculate bend allowance accurately, address common bending defects, and prioritize safety in your work. By applying the tips and techniques discussed in this article, you can elevate your skills and achieve professional results in your metalwork projects.