Urethane casting is a versatile and cost-effective method of creating high-quality prototypes and intricate designs. In this comprehensive guide, we will explore the creative possibilities of urethane casting and provide you with everything you need to know to unleash your inner artist.

Urethane casting offers a wide range of benefits compared to traditional casting methods. Its versatility allows for the creation of complex and detailed designs that may be difficult to achieve with other materials. Additionally, urethane casting is a cost-effective alternative, making it ideal for artists and designers working on a budget. The ability to produce high-quality prototypes with urethane casting further enhances its appeal to creators looking to bring their visions to life.

To get started with urethane casting, you will need a few essential materials. Urethane resin is the key ingredient in this process, providing the material from which your cast will be made. A mold release agent is also necessary to ensure the easy removal of your cast from the mold. Additionally, you will need mixing cups and stir sticks to properly mix your resin, as well as safety equipment such as gloves and goggles to protect yourself during the casting process.

Before you begin urethane casting, it is important to set up a well-ventilated area in which to work. Proper ventilation is crucial when working with urethane resin to ensure the safety of both yourself and others in the space. Organizing your materials and tools in an orderly manner will help streamline the casting process, while ensuring that you have proper safety measures in place will minimize the risk of accidents or injury.

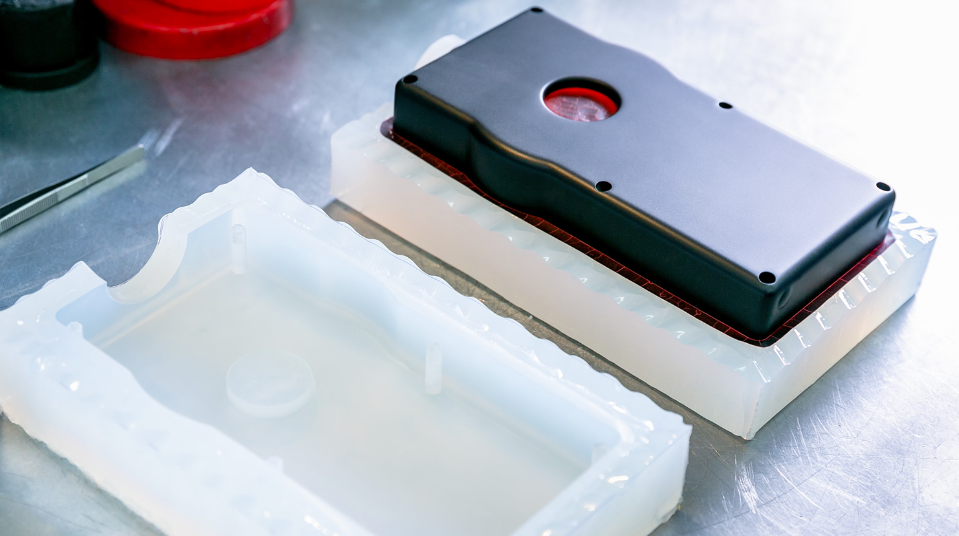

The first step in urethane casting is creating a mold in which to pour your resin. Selecting the right mold material is essential to achieving a detailed and accurate cast. Silicone molds are a popular choice for urethane casting due to their flexibility and durability. Techniques for making a silicone mold vary depending on the complexity of the design, but with practice and patience, you can achieve a mold that captures every intricate detail.

Once you have prepared your mold, it is time to mix and pour the urethane resin. Understanding the ratio of resin to hardener is crucial to ensuring that your cast sets properly. Mixing techniques such as stirring slowly and consistently will help achieve a smooth consistency in the resin, while avoiding air bubbles is essential for a flawless finish.

After allowing the resin to cure, it is time to demold your cast and begin the finishing process. Carefully removing the cast from the mold without damaging it is key to preserving the intricate details of your design. Trimming any excess material and sanding and polishing the surface will give your cast a professional finish that is ready for display or further embellishment.

For those looking to take their urethane casting to the next level, there are a variety of advanced techniques and tips to explore. Incorporating color pigments and additives into your resin can add depth and visual interest to your cast. Experimenting with different mold types, such as two-part molds or multi-piece molds, can also expand the creative possibilities of urethane casting. Finally, knowing how to troubleshoot common issues such as air bubbles or improper curing will help you master this art form and achieve stunning results.

To inspire your urethane casting projects, we have curated a selection of creative projects made with this versatile medium. From intricate jewelry and sculpture to functional prototypes and decorative objects, urethane casting offers a world of artistic possibilities waiting to be explored. We encourage you to experiment and innovate with your own projects, using the techniques and tips provided in this guide to bring your unique vision to life.

Throughout the urethane casting process, it is crucial to prioritize safety and take necessary precautions to protect yourself and those around you. Wearing protective gear such as gloves and goggles will shield you from harmful chemicals and fumes, while ensuring proper ventilation in your workspace will reduce the risk of respiratory issues. Additionally, storing and disposing of urethane materials according to manufacturer guidelines will help prevent environmental harm and keep your workspace clean and safe.

In conclusion, mastering the art of urethane casting opens up a world of creative possibilities for artists and designers alike. By following the techniques and tips outlined in this guide, you can create high-quality prototypes and intricate designs with ease. From preparing your workspace and creating detailed molds to mixing and pouring resin and finishing your cast, urethane casting offers endless opportunities for experimentation and innovation. So go ahead, unleash your inner artist and explore the boundless potential of urethane casting today.