POM injection molding produces parts made of polyoxymethylene (POM), an engineering thermoplastic that includes both homopolymer and copolymer versions of acetal. Homopolymer acetal has a highly ordered crystalline structure for increased strength, but can be difficult to process because of its precise melt temperature. Copolymer acetal has a wider range of processing temperatures, but is mechanically weaker because it only has regions of crystallinity.

Many suppliers offer copolymer acetals but only DuPont makes the resin that is used in Delrin®, a homopolymer with exceptional properties. Delrin® plastics are graded based on strength, stiffness, viscosity, and resistance, with applications that support both plastic injection molding and CNC machining. Applications for injected molded POM parts include components that are used in automotive, fluid handling, medical, and healthcare applications.

This article examines the material properties of POM plastics, the advantages of POM injection molding, and some design guidelines and processing parameters.

POM Material Properties

Below you’ll find the physical, mechanical, and molding properties of some POM trade names. The only homopolymer listed is Delrin 100, and the other POM plastics are acetal copolymers.

| Delrin® 100 BK602 | Duracon® M90-44 | Celcon® M90 | Kepital® | Hostaform | ||

| F20-03 | ®C9021 | |||||

| Physical | Density (g/cm3) | 1.42 | 1.41 | 1.41 | 1.41 | 1.41 |

| Shrinkage Rate (%) | 1.9–2.2 | 2.1–2.3 | 1.9–2.2 | 2 | 1.8–2 | |

| Rockwell Hardness | 120 R | 80 M | NA | NA | NA | |

| Mechanical | Tensile Strength at Yield (MPa) | 72 | 62 | 66 | 65 | 64 |

| Elongation at Yield (%) | 23 | 35 | 10 | 10 | 9 | |

| Flexural Modulus (GPa) | 2.9 | 2.5 | 2.55 | 2.55 | NA | |

| Flexural Strength (MPa) | NA | 87 | NA | 87 | NA | |

| Injection Molding | Drying Temperature (°C) | 80–100 | NA | 80–100 | 80–100 | 120–140 |

| Drying Time (hrs) | 2–4 | NA | 3 | 3–4 | 3–4 | |

| Melt Temperature (°C) | 215 | 200 | 205 | 180–210 | 190–210 | |

| Mold Temperature (°C) | 80–100 | 80 | 90 | 60–80 | 85 |

As the data above shows, POM has excellent tensile and flexural strength but a high shrink rate. The homopolymer Delrin® has the greatest tensile strength because of its highly ordered crystalline structure. Note that some POM grades can be modified with fillers to increase mechanical strength, corrosion resistance, or UV (ultraviolet light) resistance.

Advantages of POM Injection Molding

POM is a high-strength engineering thermoplastic that has many useful characteristics:

Fatigue resistance

Creep resistance

High strength

Low friction

Food safe

Dimensional stability

Corrosion resistance

Heat resistance

Fatigue Resistance

POM has excellent fatigue resistance and can be used in applications that have multiple load/unload cycles, such as gears. Homopolymer POM (e.g., injection molded Delrin®) has greater fatigue strength than copolymer POM.

Creep Resistance

Injection molded POM has good resistance to creep, the tendency of a solid material to undergo slow deformation when subjected to persistent mechanical stresses. POM can also be subjected to long-term loading with minimal permanent deformation.

High Strength

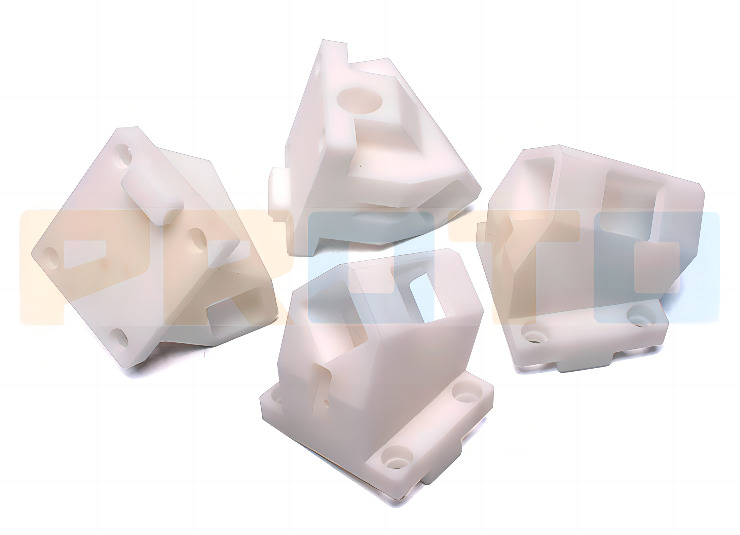

POM plastics have excellent mechanical properties for rigidity, tensile strength, and flexural strength — but homopolymer acetals have better mechanical properties. Applications for high-strength POM include conveyor belts and safety restraints.

Low Friction

POM has excellent lubricity because of its low coefficient of friction, so this engineering thermoplastic is ideal for applications where there’s exposure to sliding friction. Injection molded POM also has good resistance to wear, aka the ability of a material to resist the progressive loss of surface volume due to mechanical actions (such as repeated rubbing).

Food Safe

Injection molded POM products can be made of grades that are rated as food safe in accordance with FDA, USDA, NSF, Canada AG, or 3-A Dairy material standards. Applications include injection molded plastic parts for food processing equipment.

Dimensional Stability

Although POM has a relatively high shrinkage rate during injection molding, this plastic provides excellent dimensional stability once parts have cooled. This enables injection molded POM to retain its form and maintain its tolerances in demanding applications.

Corrosion Resistance

Because POM plastic resists most fuels and solvents, it’s often used to mold fuel tanks and chemical storage tanks. POM can be damaged by phenols, however, and it doesn’t resist strong acids and bases.

Heat Resistance

Injection molded POM can withstand continuous service temperatures up to 105°C. Homopolymer POM has higher instantaneous heat resistance and copolymer POM has a better long-term thermal resistance. POM plastic is flammable, however, and it won’t self-extinguish once it’s ignited.

POM Injection Molding Design Guidelines

For part designers, it’s important to follow some best practices and design for manufacturing (DFM) guidelines.

Wall Thickness: The recommended wall thickness for injection molded POM parts is between 0.030 and 0.125 inches. For best results, keep thickness variations to within 15% of the nominal wall thickness. Thick walls are not recommended because of POM’s high shrinkage rate. Thin walls can also be challenging to mold, and POM may be subject to underfilling or exhibit defects such as knit lines.

Tolerances: Because POM is prone to significant shrinking, thicker wall sections can adversely affect injection molding tolerances.

Radii: POM is sensitive to high-stress concentrations, so it’s important to keep radii to at least 25% of the nominal wall thickness. If your design can accommodate it, however, 75% of nominal wall thickness is optimal.

Draft Angle: POM has excellent lubricity and as such, the draft does not need to be high to ensure effective part ejection. For injection molded POM, 0.5 to 1 degrees of draft are typical. Zero draft is also possible and may be required for gears and bearings.

No Copper Contact: When molten POM contacts copper, the resulting chemical reaction causes the POM to decompose. Therefore, it’s important to avoid contact between POM plastic and copper within the injection molding system.

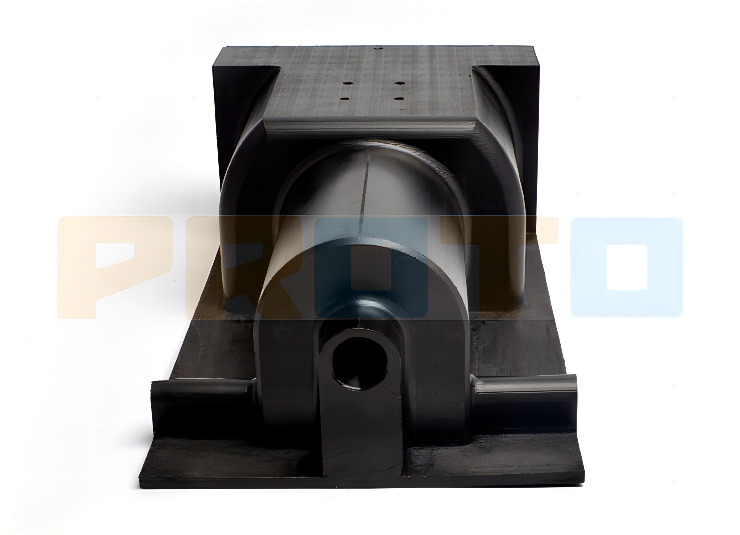

Mold Material: Stainless steel is recommended for POM injection molds because POM is highly corrosive when in its molten form. Chrome-plated molds tend to flake over time and, as such, are not recommended for use with POM.

Bonding Considerations: POM parts do not readily adhere to each other. Therefore, it’s better to design assemblies of POM parts to snap together or use other mechanical fastening methods.

POM Material Processing

POM can be challenging to process because of its high-temperature sensitivity. For injection molders, there are four key considerations.

Heat

Moisture

Molding parameters

Shrinkage

Heat

If POM is heated past its decomposition temperature, this engineering thermoplastic can break down into corrosive by-products that damage the injection mold. Therefore, it’s important to keep the temperature of molten POM below 210°C. In addition to the proper temperature, molders need to use a short heating cycle. As the temperature increases, the recommended residence time decreases. For best results, maintain mold temperatures between 60 to 100 °C.

Moisture

POM does not readily absorb moisture and has an absorption rate of only 0.2 to 0.5%. However, it’s often recommended to dry POM resin prior to processing, typically for 3 to 4 hours. The exact drying temperature depends on the POM grade.

Molding Parameters

To successfully injection mold POM parts, molders need to maintain a medium to high injection speed and an injection pressure between 70 and 120 MPa.

Shrinkage

Proper modeling is important because POM is prone to shrinkage rates of 2 to 3.5%. Most shrinkage occurs while the part is still within the mold during the cooling stage, but a small amount of shrinkage still occurs after ejection, especially for Delrin®. This homopolymer POM variant has higher shrinkage rates than copolymer acetals.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.