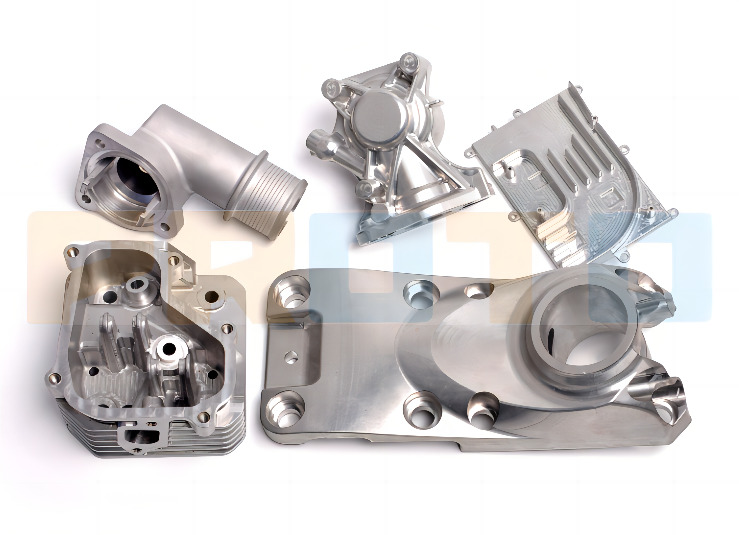

Aluminum can be manufactured with great versatility and precision through the use of precision CNC machining. It is perfect for applications needing high accuracy because it can produce extremely tight dimensional tolerances on intricate and complex parts. This essay will examine the accuracy, uses, and constraints of precision CNC aluminum machining. We’ll go over the variables that impact precision, common applications for precision CNC machining aluminum parts, and process limitations.

How Precise Can CNC Machining Be With Aluminum?

CNC machining is a highly accurate and adaptable manufacturing technique that works particularly well with aluminum. It is perfect for applications needing high accuracy because it can produce extremely tight dimensional tolerances on intricate and complex parts.

Precision Levels:

Typical Tolerances: Tolerances of ±0.001 inches (0.025 mm) are achievable for the majority of aluminum CNC machining projects. Applications for this level of precision are numerous and include everything from aerospace parts to medical devices.

Pushing the Limits: It is possible to achieve even tighter tolerances in some instances, as little as ±0.0005 inches (0.013 mm). Though it is possible for applications requiring extraordinary accuracy, like optical instruments or scientific research equipment, it does require specialized equipment and expertise.

Factors Affecting Precision:

Machine Quality: The CNC machine’s own quality and capabilities are very important. Significantly tighter tolerances can be achieved by high-end machines with sophisticated features like vibration control and thermal stability, which set them apart from older or less advanced machines.

Tooling: Precision is also impacted by the kind and state of the cutting tools that are employed. Cleaner cuts and tighter tolerances can be achieved with high-quality, precisely-crafted tools composed of the right materials.

Material: The machinability of various aluminum alloys varies. While some alloys are harder and more prone to deflection, others are softer and easier to machine. It is crucial to select the appropriate alloy for the required degree of precision.

Programming and Setup: Crucial elements include the knowledge and expertise of the machinist who sets up the machine and the programmer who writes the CNC code. Inaccurate parts can result from improper setup or programming errors.

What Are the Typical Applications for Precision CNC Machining Aluminum Parts?

CNC machining is the method of choice for creating precise and complex aluminum parts for a wide range of industries due to its high precision and versatility. Here are some typical applications:

Aircraft parts: Control systems, landing gear parts, structural elements, and engine casings are all dependent on precisely machined aluminum parts that are lightweight and long-lasting.

Satellites and spacecraft: For crucial parts like antennas, instruments, and structural elements, precision machining guarantees precise geometries and tolerances.

Implants and prosthetics: Biocompatible aluminum alloys are machined for use in bone plates, joint replacements, and other implants where sterile surfaces and extreme precision are necessary.

Surgical instruments: CNC machining produces smooth, dimensionally accurate aluminum parts that are useful for tools like forceps and scalpels.

Heat sinks: For electronics, effective heat dissipation is essential. The best possible thermal management for CPUs, GPUs, and other parts is provided by CNC-machined aluminum heat sinks.

Casings and enclosures: Electronic device housings are made both aesthetically pleasing and functional by the precise dimensions and surface finishes of machined aluminum.

Engine parts: For exact fit and functionality, lightweight, strong aluminum parts like engine blocks, cylinder heads, and pistons are frequently CNC machined.

Suspension and chassis parts: For lightweight and durable parts like suspension arms, brake calipers, and chassis reinforcements, high-strength aluminum alloys are machined.

What Are the Limitations of CNC Machining Aluminum?

Aluminum can be machined with amazing accuracy and versatility using CNC, but there are certain drawbacks you should be aware of before using aluminum for your project. Here are some key points to keep in mind:

Cost: CNC machining can be more costly than other manufacturing processes like casting or forging, particularly when producing intricate parts with precise tolerances. This is because it requires specialized labor, sophisticated machinery, and a longer production period.

Material limitations: Although aluminum is very machine-friendly, it is not as strong or heat-resistant as some other materials, such as titanium or steel. In applications where high strength or heat tolerance is required, different materials may be needed.

Design constraints: Certain designs might not be a good fit for CNC machining, especially if they have internal features or undercuts that are hard to reach with cutting tools. Furthermore, it can be difficult to machine precisely around thin walls and sharp corners.

Tool wear and tear: Aluminum can be abrasive and accelerate the deterioration of cutting tools, especially in softer alloys. This may result in higher production costs and more frequent tool replacements.

Surface finish limitations: Even though CNC machining can produce a wide range of surface finishes, it may not be able to produce certain textures or fine details. For finishes that are extremely glossy or mirror-like, more post-processing steps, such as polishing, may be required.

Environmental considerations: Metal chips and coolant waste are produced during CNC machining of aluminum and must be properly disposed of or recycled. This may increase the impact on the environment and raise the cost of waste management.

Conclusion

Aluminum can be manufactured using a variety of techniques, including precision CNC machining, which can be used to make both simple and complex parts. It is a good option for high-precision and accuracy applications like electronics, medical devices, and aerospace. You can decide if precision CNC machining of aluminum is the best option for your project by being aware of the accuracy, uses, and constraints of this process. Proto MFG is a professional manufacturer dedicated to providing CNC machining services. For more information, please contact us.