The evolution of CNC machining has revolutionized the way products are manufactured, replacing manual labor with computer-controlled precision. Automation has played a crucial role in advancing the capabilities of the manufacturing industry, streamlining processes and increasing productivity.

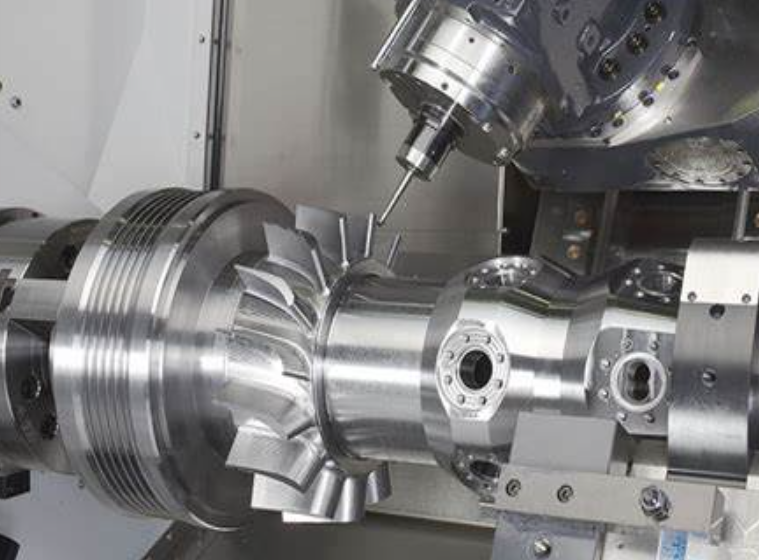

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computerized systems to control machine tools. This technology translates design specifications into precise movements, allowing for the creation of complex and detailed parts with high accuracy. The benefits of CNC machining include increased efficiency, repeatability, and the ability to produce intricate components that would be nearly impossible to create manually.

Automation in CNC machining refers to the use of computer-controlled systems to perform tasks traditionally done by human operators. This includes loading materials, changing tools, and monitoring the machining process. By automating these tasks, manufacturers can increase production efficiency, reduce human error, and achieve consistent quality in their output. Various types of automated systems, such as robotic arms and pallet changers, are commonly used in CNC machining to streamline operations.

The integration of robotics in CNC machining has further enhanced the capabilities of automated systems. Robots can perform a wide range of tasks, from handling raw materials to finishing products, with speed and precision. The benefits of using robots in CNC machining include increased productivity, improved safety conditions for workers, and the ability to operate 24/7 without fatigue. Examples of robotic applications in CNC machining include automated loading and unloading of parts, as well as the use of vision systems for quality control.

As technology continues to advance, the future of CNC machining holds exciting possibilities. Emerging technologies, such as additive manufacturing and digital twinning, are shaping the way products are designed and produced. The integration of artificial intelligence and machine learning algorithms is also revolutionizing the manufacturing industry, allowing for predictive maintenance and real-time optimization of machining processes. Predictions for the future of CNC machining include increased customization, shorter lead times, and higher levels of automation.

Despite the numerous benefits of automation in CNC machining, manufacturers often face challenges in implementing these systems. Common obstacles include high initial costs, complex integration processes, and the need for specialized training. Strategies to overcome these challenges include thorough planning, investing in employee training, and partnering with experienced automation providers. Case studies of successful implementations demonstrate the potential of automation in improving productivity and efficiency in CNC machining operations.

Automation To successfully implement automation in CNC machining, companies must follow a set of best practices. This includes defining clear objectives, conducting thorough research on available technologies, and developing a comprehensive implementation plan. Employee training is essential to ensure that staff are equipped to operate and maintain automated systems effectively. Regular maintenance and monitoring of automated equipment are also crucial to prevent downtime and ensure optimal performance.

Cost Considerations The initial investment for automation in CNC machining can be significant, but the long-term cost-saving benefits can outweigh the upfront expenses. Calculating return on investment (ROI) for automation requires a thorough analysis of factors such as increased production capacity, reduced labor costs, and improved product quality. By streamlining processes and increasing efficiency, automation can help companies achieve a competitive edge in the market.

Maintaining quality control in automated CNC machining is essential to ensure that parts meet design specifications and industry standards. Tools and techniques for quality assurance include in-process monitoring, inspection tools, and statistical process control. By implementing rigorous quality control measures, manufacturers can guarantee the precision and accuracy of their products, leading to higher customer satisfaction and improved reputation.

Various industries benefit from automated CNC machining, including aerospace, automotive, and medical device manufacturing. Case studies of successful automation implementations showcase the versatility and efficiency of automated systems in different applications. Future trends in industry applications of CNC machining include the adoption of smart manufacturing technologies, real-time data analytics, and collaborative robotics for enhanced productivity and agility.

Sustainability practices in CNC machining with automation are becoming increasingly important as companies strive to minimize waste and energy consumption. By optimizing processes and reducing material waste, manufacturers can lower their carbon footprint and contribute to a cleaner environment. Advantages of environmentally-friendly machining processes include cost savings, regulatory compliance, and improved corporate social responsibility.

Regulatory Compliance Regulations and standards for automated CNC machining ensure the safety and quality of products manufactured using these technologies. Compliance requirements may include machine safety standards, environmental regulations, and quality management systems certification. Best practices for maintaining compliance include regular audits, documentation of procedures, and ongoing training for employees to uphold industry standards.

Training and Education Training in automated CNC machining is essential for employees to understand how to operate and maintain complex equipment effectively. Educational resources, such as online courses, workshops, and certification programs, provide valuable knowledge and skills for professionals in the manufacturing industry. By investing in training and education, companies can ensure that their workforce is equipped to handle the challenges of automation and embrace new technologies in CNC machining.

The transformative power of automation in CNC machining is evident in the industry’s advancements in efficiency, precision, and productivity. Embracing robotics and automation can revolutionize manufacturing processes, leading to increased competitiveness and innovation. As companies continue to adopt automated systems, the future of CNC machining looks promising, with endless possibilities for growth and development in the digital age. Revolutionizing CNC machining with automation is not just a trend but a necessity for companies looking to stay ahead in a rapidly evolving industry.