Proto tooling is the backbone of the manufacturing industry, providing crucial support in the development of new products and processes. As technology advances at a rapid pace, so does the field of prototyping, with innovative trends shaping the future of manufacturing. In this article, we will delve into the world of prototyping, exploring the importance of advancements in this area and the impact they have on the industry.

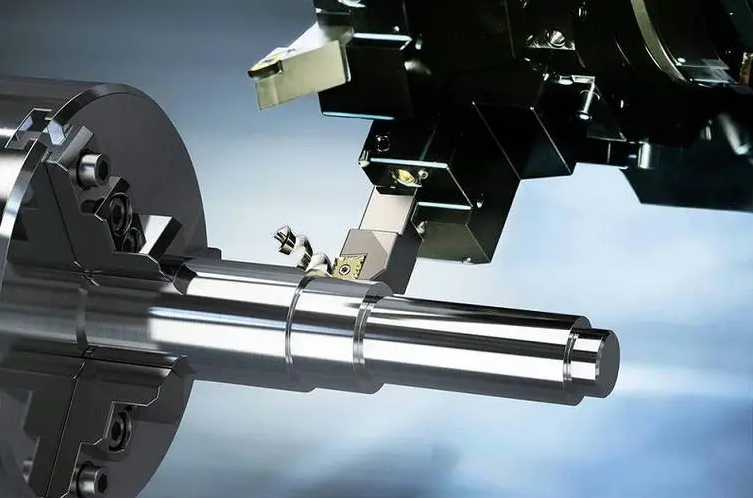

Traditional proto tooling methods have long been the go-to for manufacturers, relying on manual processes and traditional machining techniques. While effective, these methods often come with limitations, such as longer lead times and higher costs. Manufacturers face challenges in meeting the demands of consumers for faster, more efficient production processes. This has led to a shift towards embracing new technologies in prototyping.

One of the most significant advancements in prototyping is the introduction of 3D printing. This technology allows for rapid prototyping and the creation of complex geometries that were previously unattainable. The incorporation of artificial intelligence in prototyping has also revolutionized the industry, enabling machines to learn and adapt to optimize performance. Additive manufacturing has quickly gained popularity in prototyping due to its cost-effectiveness and efficiency.

Virtual reality has been a game-changer in prototyping, offering designers the ability to create virtual prototypes with incredible detail and accuracy. VR simulation allows manufacturers to test their designs in a virtual environment before physical production, saving time and resources. Additionally, VR is utilized for training purposes in prototyping, providing a safe and immersive learning experience for operators.

Nanotechnology has paved the way for enhanced durability in tooling, with nanomaterials offering unprecedented strength and resilience. Nanoscale manufacturing processes ensure precision in prototyping, allowing for intricate designs and tight tolerances. The applications of nanotechnology in the tooling industry are vast, promising a future of innovation and advancement.

Automation plays a vital role in prototyping processes, increasing efficiency and productivity. Robotics in prototyping offer advantages such as reduced human error, improved consistency, and faster production cycles. The future trends in robotic proto tooling point towards a more streamlined and autonomous manufacturing environment.

The integration of the Internet of Things in proto tooling has led to the development of smart tools for monitoring and maintenance. IoT-enabled prototyping equipment allows manufacturers to track performance metrics in real-time and optimize operations. The implications of IoT in proto tooling efficiency are profound, offering insights and data-driven solutions for improved productivity.

As the world shifts towards more sustainable practices, the tooling industry is following suit. Eco-friendly proto tooling practices involve the use of recyclable materials and green initiatives to minimize environmental impact. Manufacturers are embracing sustainable solutions to create a more responsible and eco-conscious manufacturing sector.

The emergence of 5G technology is set to revolutionize prototyping, enabling faster prototyping and data transfer. Cloud-based prototyping solutions offer flexibility and scalability for manufacturers, allowing for seamless collaboration and remote access. Customization in proto tooling is on the rise, catering to diverse industries with unique requirements.

The future of proto tooling looks promising, with advancements in research and development driving innovation in the industry. Industry 4.0 is set to transform prototyping processes, integrating cutting-edge technologies for enhanced efficiency and productivity. The vision for the future of prototyping is bright, with endless possibilities for growth and evolution.

In conclusion, the advancements in prototyping are shaping the future of manufacturing, offering exciting opportunities for innovation and growth. By embracing revolutionary technologies in prototyping, manufacturers can stay ahead of the curve and meet the demands of an ever-evolving market. It is essential for industry professionals to keep pace with the latest trends and developments in prototyping to remain competitive in the rapidly changing landscape of manufacturing. Embracing change and adopting new technologies is key to revolutionizing prototyping and driving the industry towards a more efficient and sustainable future.