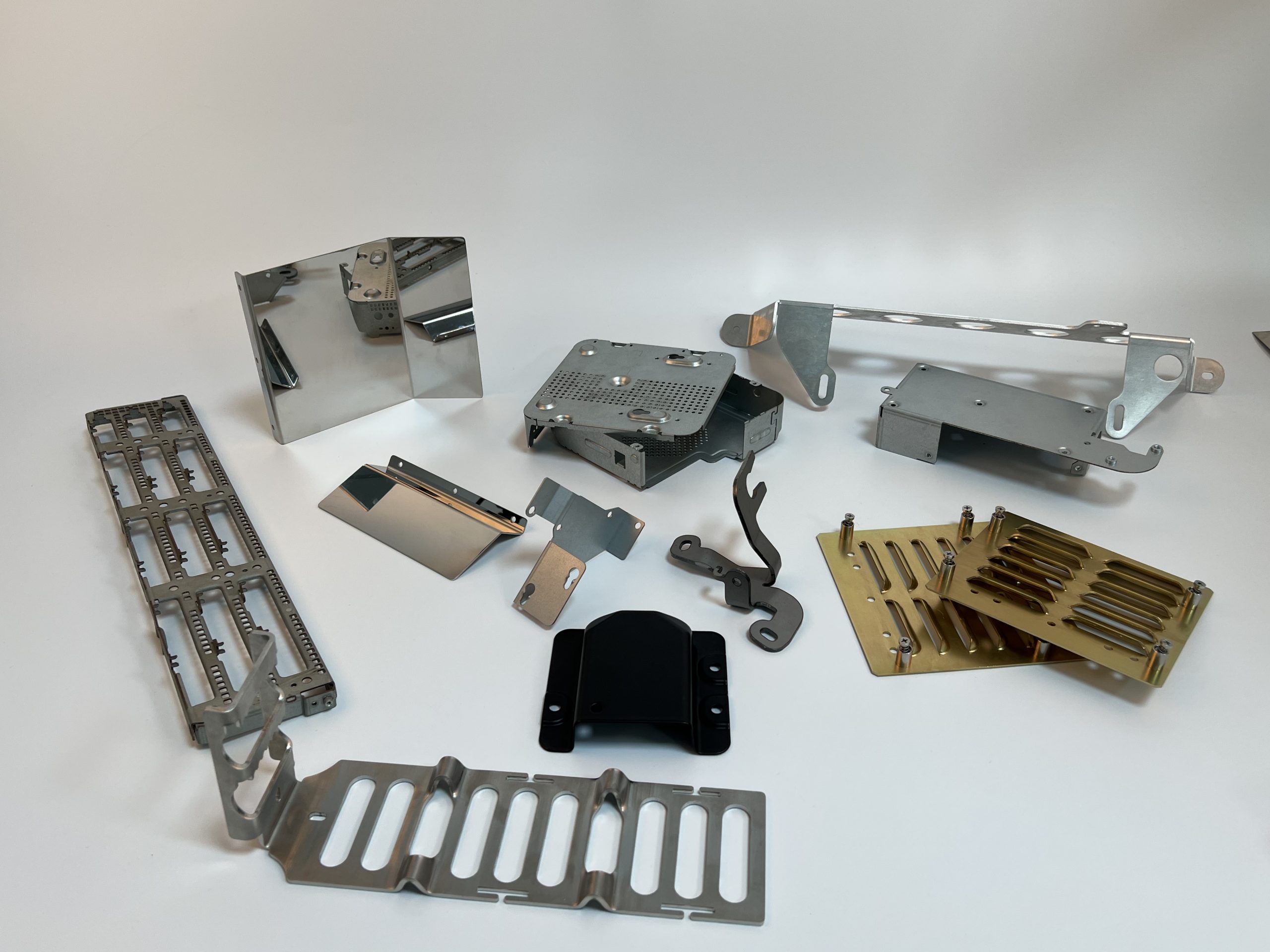

Sheet metal fabrication is a meticulous process that requires precision and care to achieve successful results. Whether you are a seasoned professional or a DIY hobbyist, it is crucial to understand the importance of taking precautions throughout the fabrication process to ensure the quality and durability of your projects. In this blog post, we will explore expert tips and tricks for handling sheet metal fabrication with care and precision, as well as common pitfalls to avoid. By following these guidelines, you can ensure the success of your projects and achieve professional results.

Sheet metal comes in a variety of materials, each with its own unique properties and characteristics. Common types of sheet metal materials include steel, aluminum, and stainless steel, each suitable for different applications based on factors such as strength, corrosion resistance, and cost-effectiveness. When selecting the right material for your project, it is important to consider these factors to ensure the desired outcome.

In addition to different materials, there are also various sheet metal fabrication techniques, such as bending, cutting, and welding, each requiring specific tools and skills to execute effectively. Choosing the right fabrication technique for your project is essential to achieve the desired shape and structure. The importance of selecting the appropriate material and technique cannot be overstated, as they directly impact the quality and longevity of the finished product.

Safety First: Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is a crucial aspect of sheet metal fabrication, as it helps protect workers from potential hazards such as sharp edges, flying debris, and fumes. PPE includes items such as safety goggles, gloves, and ear protection, each serving a specific purpose to ensure the safety of the fabricator. Properly wearing and maintaining PPE is essential to prevent injuries and accidents during the fabrication process.

When selecting PPE for sheet metal fabrication, it is important to choose items that provide adequate protection while allowing for dexterity and comfort. In addition, regular inspection and maintenance of PPE are necessary to ensure its effectiveness. By following proper usage guidelines and taking care of your PPE, you can minimize the risk of injury and ensure a safe working environment.

Having the right tools and equipment is essential for successful sheet metal fabrication projects. Essential tools for sheet metal fabrication include shears, punches, and benders, each designed for specific tasks such as cutting, drilling, and shaping metal. Proper maintenance and storage of tools are essential to prolong their lifespan and ensure optimal performance.

When selecting equipment for a project, it is important to consider the specific requirements and limitations of the job. Whether you are working on a small-scale project at home or a large industrial project, choosing the right equipment can make a significant difference in the efficiency and quality of the finished product. By investing in high-quality tools and equipment, you can achieve professional results and avoid unnecessary complications.

Proper planning is essential before starting any sheet metal fabrication project to ensure a smooth and successful outcome. Accurately measuring and cutting sheet metal is crucial to achieving the desired shape and dimensions. Creating accurate templates and patterns can help streamline the fabrication process and minimize errors.

During the planning phase, it is important to consider factors such as material thickness, bending radius, and tolerances to ensure the accuracy of the final product. By taking the time to plan and prepare before starting a project, you can avoid costly mistakes and achieve precise results. Additionally, proper planning helps optimize material usage and minimize waste, resulting in a more cost-effective and sustainable fabrication process.

Cleaning and deburring sheet metal before fabrication is essential to remove dirt, oil, and other contaminants that can affect the quality of the finished product. There are various methods for cleaning sheet metal, including chemical cleaning, abrasive blasting, and mechanical cleaning, each suitable for different types of contaminants. Deburring sharp edges is equally important to prevent injuries and ensure a smooth finish.

Achieving smooth and clean edges is essential for creating a professional-looking product that meets industry standards. By implementing proper cleaning and deburring techniques, you can enhance the overall quality and appearance of your projects. Taking the time to remove imperfections and irregularities from the surface of the metal can significantly improve the final result and increase customer satisfaction.

In sheet metal fabrication, there are common pitfalls that fabricators must avoid to ensure the success of their projects. These include errors such as improper measurements, incorrect tool selection, and inadequate material handling, each of which can lead to costly delays and rework. By understanding these common mistakes and taking steps to prevent them, you can streamline the fabrication process and achieve consistent results.

Troubleshooting common issues that arise during fabrication is an important skill for any fabricator to develop. Whether dealing with warping, distortion, or other problems, knowing how to address these challenges effectively can save time and resources. By staying aware of potential pitfalls and proactively addressing issues as they arise, you can maintain the quality and integrity of your projects throughout the fabrication process.

Precision and accuracy are essential aspects of sheet metal fabrication that can make the difference between a professional-looking product and a subpar result. Achieving accurate measurements and cuts is crucial to ensure the proper fit and functionality of the finished product. Consistent results rely on precise execution and attention to detail at every stage of the fabrication process.

Using advanced tools and techniques can help improve the precision of your projects and minimize errors. Whether utilizing computer-aided design (CAD) software or precision cutting tools, investing in technology can enhance the quality and efficiency of your work. By prioritizing precision and accuracy in your sheet metal fabrication projects, you can create products that meet the highest standards and exceed customer expectations.

Proper handling and storage of sheet metal are essential to prevent damage and maintain the integrity of the material. Handling metal sheets with care, avoiding excessive bending or dropping, is crucial to prevent deformation and surface damage. Storing sheet metal in a dry, well-ventilated area away from direct sunlight and moisture helps preserve its condition and prevent corrosion.

Protecting sheet metal from environmental factors such as humidity, temperature fluctuations, and chemical exposure is key to ensuring its longevity. By implementing proper handling and storage techniques, you can extend the lifespan of the material and maintain its physical properties over time. Taking the time to handle and store sheet metal correctly can help you avoid unnecessary waste and ensure the success of your fabrication projects.

Finishing techniques play a significant role in enhancing the appearance and durability of sheet metal projects. Whether applying paint, powder coating, or other finishing options, choosing the right technique can significantly impact the final result. Achieving a professional finish requires attention to detail and proper application of the selected finish.

Cleaning and maintaining finished projects is equally important to preserve the quality and appearance of the material. Regular cleaning, inspection, and touch-ups can help prolong the lifespan of sheet metal projects and maintain their visual appeal. By following best practices for finishing and maintenance, you can ensure that your projects remain in top condition and continue to impress customers for years to come.

Quality control is a critical aspect of sheet metal fabrication that ensures the integrity and functionality of the finished product. Inspecting and testing finished projects for defects, accuracy, and consistency is essential to identify any issues that may require correction. By implementing quality control measures throughout the fabrication process, you can maintain high standards and deliver products that meet or exceed customer expectations.

Ensuring the durability and longevity of your projects requires a commitment to quality control and continuous improvement. By incorporating feedback from customers, employees, and industry experts, you can refine your processes and enhance the overall quality of your work. Investing in quality control measures not only benefits your business but also helps build trust and loyalty among your customers.

In conclusion, sheet metal fabrication is a complex and demanding process that requires careful planning, precision, and attention to detail. By following expert tips and taking precautions throughout the fabrication process, you can achieve professional results and ensure the success of your projects. From selecting the right materials and tools to implementing quality control measures and finishing techniques, each step plays a crucial role in the overall outcome of your work.

It is essential to prioritize safety and quality in sheet metal fabrication to protect yourself and your projects from potential hazards and errors. By following the guidelines outlined in this blog post, you can avoid common pitfalls, achieve accurate and consistent results, and create products that meet the highest standards. Whether you are a seasoned professional or a beginner in the field of sheet metal fabrication, applying these tips and tricks will help you succeed in your projects and exceed expectations.