Sheet metal fabrication is an essential skill that opens up a world of possibilities in the world of manufacturing and construction. From intricate designs to sturdy structures, the ability to work with sheet metal allows artisans and engineers alike to create objects that are both functional and beautiful. In this ultimate guide, we will explore the ins and outs of sheet metal fabrication, providing you with expert tips and techniques to help you become a pro in no time.

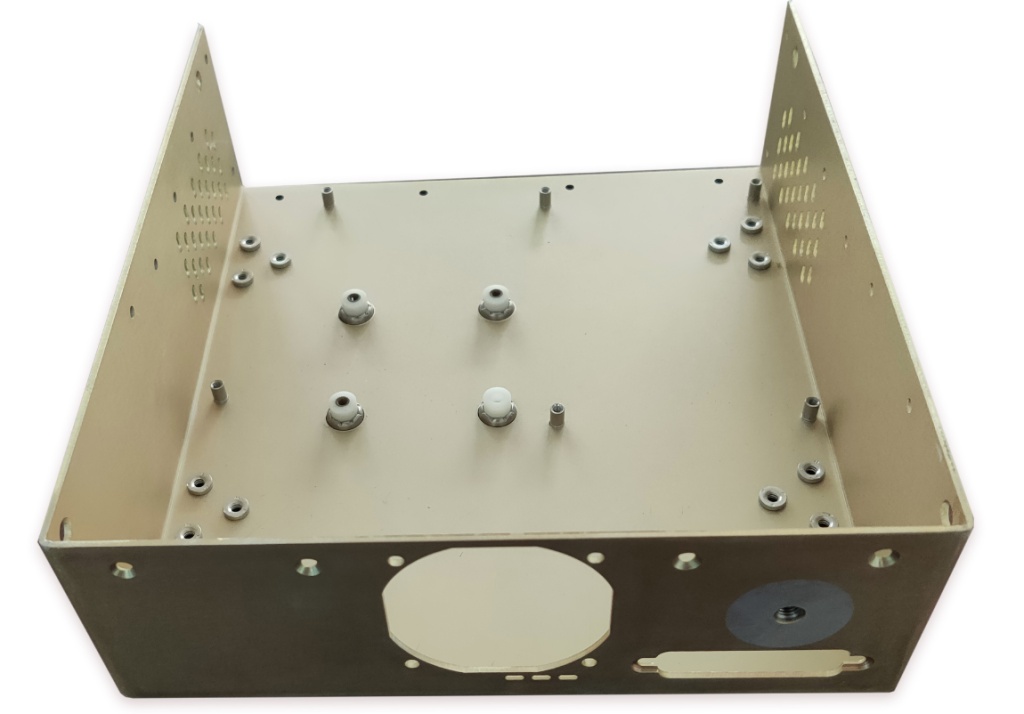

Sheet metal fabrication involves the process of transforming flat sheets of metal into finished products through cutting, shaping, and joining techniques. Common types of sheet metal materials include steel, aluminum, and copper, each with its own unique properties and applications. To get started with sheet metal fabrication, you will need a set of basic tools and equipment such as shears, saws, bending machines, and welding machines.

Sheet metal comes in a variety of alloys, each with different strengths, ductility, and corrosion resistance. When choosing the right material for your project, it is important to consider factors such as the required strength and durability. Understanding the properties of sheet metal will help you make informed decisions when it comes to material selection and fabrication techniques.

To shape sheet metal, various cutting techniques such as shearing, sawing, and laser cutting can be used to achieve precise cuts. Additionally, shaping methods like bending, stretching, and deep drawing allow for the creation of complex forms and structures. By mastering these techniques and following tips for achieving precise cuts and shapes, you can bring your sheet metal projects to life with precision and accuracy.

Joining sheet metal pieces together requires the use of techniques such as welding (MIG, TIG, spot welding), riveting, and adhesive bonding. Each method offers its own advantages and challenges, depending on the material and project requirements. By understanding the strengths and limitations of different joining techniques, you can choose the most suitable method for your project.

Once the fabrication process is complete, finishing techniques such as surface preparation, polishing, and deburring are essential to achieve a clean and professional look. Additionally, options like anodizing and plating can provide added protection and aesthetic appeal to your sheet metal projects. By mastering these finishing techniques, you can take your creations to the next level.

For those looking to push the boundaries of sheet metal fabrication, advanced techniques such as CNC machining, hydroforming, and laser cutting offer new possibilities for intricate designs and complex shapes. By exploring these advanced methods, you can take your sheet metal projects to new heights of creativity and innovation.

When designing for sheet metal fabrication, it is important to consider factors such as material thickness, bending radii, and tolerance levels. Designing for manufacturability ensures that your project can be efficiently produced while meeting quality standards. Utilizing software tools specifically designed for sheet metal design can streamline the design process and help you create accurate and detailed designs.

In the world of sheet metal fabrication, issues such as warping, distortion, scratches, and dents can arise during the fabrication process. By understanding how to deal with common problems and implementing preventative measures, you can avoid costly mistakes and ensure the quality of your finished products. With the right know-how and attention to detail, you can troubleshoot and fix issues that may arise in your sheet metal projects.

Safety should always be a top priority when working with sheet metal materials. Proper protective gear, such as gloves, goggles, and ear protection, is essential to prevent injuries during the fabrication process. Additionally, knowing how to handle sheet metal safely and implementing fire safety precautions in the workshop will help create a secure working environment for yourself and others.

Whether you are a beginner looking to start your sheet metal fabrication journey or an experienced fabricator seeking new challenges, there are a plethora of project ideas to explore. From DIY projects for beginners to intermediate and advanced project ideas, the possibilities for sheet metal fabrication are endless. Finding inspiration in everyday objects, nature, or architectural design can help spark your creativity and guide you in your next sheet metal project.

As technology continues to evolve, the world of sheet metal fabrication is also seeing advancements in automation, robotics, and sustainability practices. Emerging trends in digital fabrication and additive manufacturing are reshaping the industry, offering new possibilities for creativity and efficiency. By embracing these trends and practices, fabricators can stay ahead of the curve and contribute to a more sustainable and innovative future in sheet metal fabrication.

In conclusion, mastering sheet metal fabrication is a journey that requires skill, precision, and creativity. By understanding the basics of sheet metal fabrication, exploring advanced techniques, and designing with manufacturability in mind, you can create high-quality products with confidence and efficiency. With safety as a top priority and a commitment to continuous learning and improvement, you can unlock the secrets of sheet metal fabrication and embark on a fulfilling and rewarding journey in the world of metalworking. Start your sheet metal fabrication journey today and see where your creativity and skills can take you.