Plastics

Anodizing Type III / Hardcoat Anodizing

Mar,08 2023

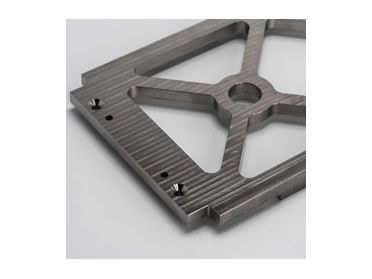

Anodizing Type III, also known as hard anodizing, produces a much thicker and denser layer of aluminum oxide than Type II anodizing. The layer is typically between 25 and 100 microns thick. This layer is harder, more wear-resistant, and provides better corrosion resistance than Type II anodizing. Anodizing Type III is often used for high-wear applications, such as aerospace components, firearm parts, and hydraulic pistons.

Anodizing Type II

Feb,07 2023

Anodizing Type II is a process that involves creating a protective oxide layer on metals using an electrolytic solution. This process has become increasingly popular in various industries because it not only improves durability but also enhances aesthetics.