After the product graphic design is completed or a new product drawing is completed, before it is put on the market, the market benefit analysis of the product will be done, or to confirm whether there is any difference between the drawing and the actual product or whether the design is reasonable. Prototype production is an inevitable process for enterprises.

CNC is a computer numerical control machine tool that is excavated from a full plate according to a numbered program. Uses the Mastercam system, which is mainly used to control the CNC tool path. CNC milling machines are specially used to process some square and irregular objects, while lathes are used to process round objects. CNC can process some relatively large workpieces. The maximum can reach 1800*900*600. It is cheaper than SLA and has many types of prototypes.

CNC prototype model production process: accept drawings → write tool paths → transfer tool paths to CNC machining center → machine automated processing → manual post-processing (polishing, painting, printing, etc.)!

It is currently the most widely used in the country. The main materials are ABS, PC, PMMA, and the metals are mainly aluminum and copper. CNC machining can process product samples with relatively high precision. The main application materials are ABS, PC, PMMA, PP, aluminum, copper, etc. Bakelite and aluminum alloy are commonly used when making products such as jigs and fixtures; CNC prototype advantages : Good toughness, high tensile strength, low cost, wide material selection.

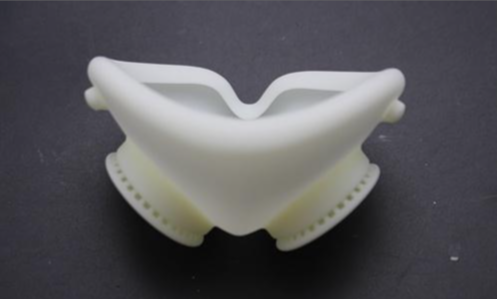

Replica molding is to use the original template to make a silicone mold in a vacuum state, and use PU material to cast it in a vacuum state, thereby cloning a copy that is the same as the original model, has higher temperature resistance, and has better strength and hardness than the original model.

If the customer requires several sets or dozens of sets, this method is suitable, which greatly reduces the cost. The product samples produced by vacuum copy molding will shrink by a certain percentage. Generally speaking, the cost of vacuum copying product samples will be lower than that of CNC. That is, the price of CNC processing of multiple sets of samples is lower than the price of CNC processing of one set and then vacuum copying of the mold.