Sheet metal is a crucial material in various industries due to its versatility and durability. Its ability to be molded into intricate shapes while maintaining strength makes it indispensable in automotive, construction, and manufacturing sectors.

Automotive Industry Applications In the automotive industry, sheet metal is utilized for exterior body panels, chassis components, and engine parts. The lightweight yet sturdy nature of sheet metal makes it an ideal material for vehicles, providing both form and function.

Industry Applications Sheet metal finds its place in the construction industry for roofing materials, HVAC ductwork, and structural framing. Its resistance to corrosion and ability to withstand harsh weather conditions make it a popular choice for these applications.

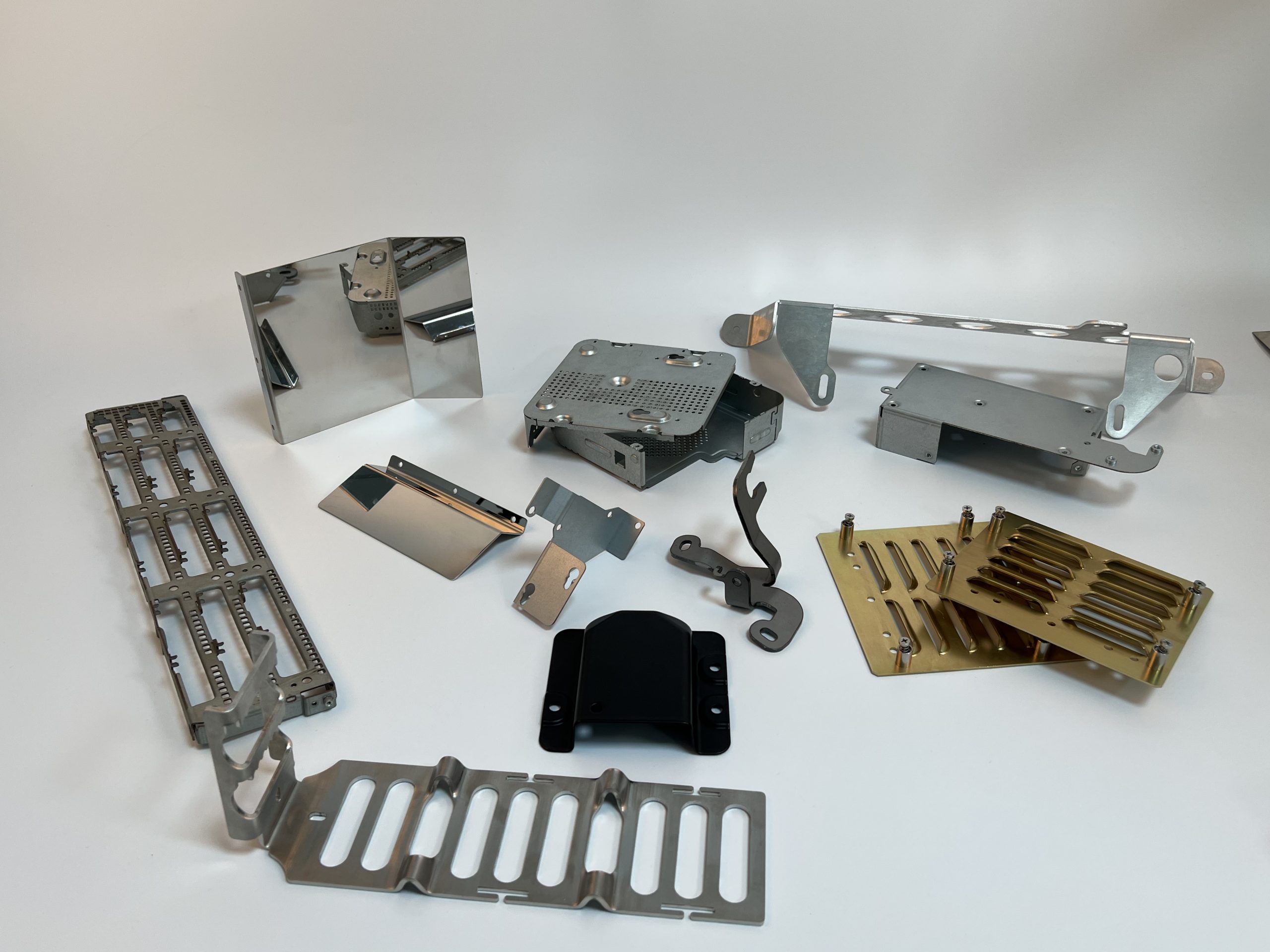

Manufacturing Industry Applications In the manufacturing sector, sheet metal is used for machinery fabrication, tool and die making, and prototype development. Its versatility and ease of customization play a crucial role in streamlining production processes.

Sheet Metal Fabrication Techniques Various cutting methods such as laser cutting and waterjet cutting, bending techniques, and welding processes are employed in sheet metal fabrication. These techniques ensure precision and efficiency in creating complex metal structures.

Selection When selecting sheet metal, factors such as material types (steel, aluminum, copper), thickness options, and surface finishes must be considered. Each material has its unique properties that cater to specific needs in various applications.

The high strength-to-weight ratio, cost-effectiveness, and customization possibilities are key advantages of using sheet metal. Its ability to provide structural integrity while being lightweight and cost-efficient makes it a top choice for many industries.

Fabrication Challenges in sheet metal fabrication include material waste, design limitations, and post-processing requirements. Overcoming these challenges requires innovative solutions and advanced technologies in the fabrication process.

Products Emerging trends such as metal 3D printing, composite material integration, and smart sheet metal technologies are transforming the sheet metal industry. These innovations open up new possibilities for creating unique and complex metal structures.

Considering the environmental impact, sheet metal recycling initiatives, energy efficiency in production, and sustainable design practices are becoming increasingly important. Implementing eco-friendly practices in sheet metal manufacturing is essential for a greener future.

Industry Future trends in the sheet metal industry include lightweighting initiatives, digital transformation in fabrication processes, and integration of IoT in sheet metal applications. These advancements are shaping the future of sheet metal fabrication and opening up new opportunities for innovation.

Case Studies of Successful Sheet Metal Projects Iconic architectural structures, cutting-edge automotive designs, and innovative product prototypes showcase the versatility and creativity in sheet metal applications. These case studies demonstrate the endless possibilities and potential of sheet metal in diverse projects.

Training and Education in Sheet Metal Fabrication Vocational programs, industry certifications, and ongoing professional development opportunities play a crucial role in training individuals in sheet metal fabrication. Continuous learning and skill development are essential to excel in the rapidly evolving sheet metal industry.

Industry Regulations and Standards Adhering to industry regulations and standards, such as OSHA guidelines, material safety requirements, and quality control measures, is necessary to ensure safety and quality in sheet metal fabrication. Compliance with these standards is essential for maintaining high industry standards.

Collaboration Opportunities in Sheet Metal Industry Collaboration opportunities in the sheet metal industry include supplier partnerships, design collaboration platforms, and research and development consortiums. Working together with industry experts and partners facilitates innovation and growth in sheet metal applications.

In conclusion, sheet metal plays a crucial role in modern industries due to its versatility and importance. Exploring new applications and innovations in sheet metal use is essential for driving progress and meeting the evolving needs of various sectors. As technology advances and new materials are introduced, the future of sheet metal holds exciting possibilities for creativity and ingenuity.