Custom sheet metal fabrication is a versatile and innovative process that allows for endless possibilities in design and construction. Whether you’re looking to add a unique touch to your home decor or create a one-of-a-kind piece of art, Sheet metal customization can help you achieve your vision. The ability to customize every aspect of the metal, from its shape to its finish, makes it a popular choice for a wide range of projects.

One of the key benefits of Sheet metal customization is its durability and longevity. Unlike mass-produced metal products, Sheet metal customization is built to last, ensuring that your creation will withstand the test of time. Additionally, Sheet metal customization offers a wide range of customization options, allowing you to tailor the design to fit your exact specifications. This level of customization also opens up the possibility for unique shapes and designs that are not possible with off-the-shelf metal products. Finally, Sheet metal customization fabrication is often more cost-effective than you might think, especially when you consider the long-term value of a well-crafted, custom-made piece.

Custom sheet metal fabrication is used in a variety of industries and applications. In architecture and interior design, custom metalwork can add a touch of elegance and sophistication to any space. From metal accents to custom furniture, the possibilities are endless. In the automotive industry, Sheet metal customizatio is often used for custom bodywork and performance upgrades. Artists and sculptors also rely on Sheet metal customization to bring their creative visions to life, creating unique and eye-catching pieces. And in the industrial sector, custom sheet metal fabrication is used for everything from machinery parts to custom signage.

When it comes to custom sheet metal fabrication, there are a variety of materials to choose from. Steel is a popular choice for its strength and versatility, making it ideal for a wide range of projects. Aluminum is lightweight and corrosion-resistant, making it a great option for outdoor applications. Copper and brass are prized for their warmth and beauty, while titanium offers unmatched strength and durability. Each material has its own unique qualities, allowing you to choose the perfect option for your specific project.

When designing a Sheet metal customization project, there are several key considerations to keep in mind. The thickness and gauge of the metal will determine its strength and durability, so be sure to choose the right option for your needs. Finishes and coatings can add a decorative touch, while texture and patterns can create visual interest. Joining methods such as welding and soldering are important for ensuring a strong, secure bond between metal pieces.

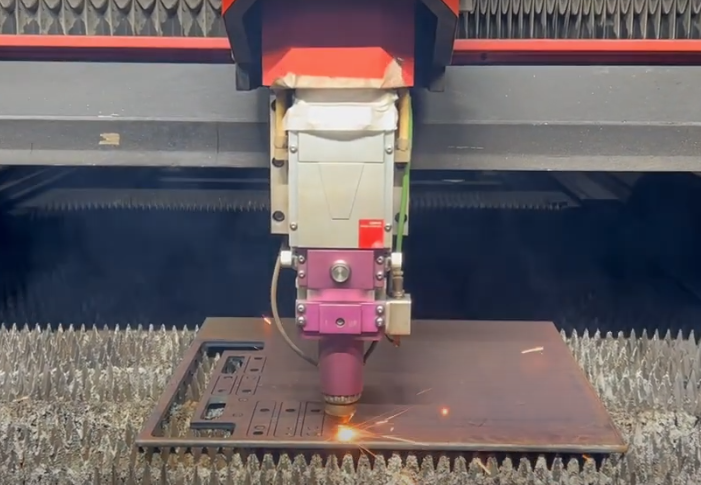

Custom sheet metal fabrication involves a variety of techniques to shape and manipulate the metal. Cutting and bending are fundamental processes that determine the overall form of the metal. Welding and soldering are used to join pieces together, while stamping and punching create intricate designs and patterns. Forming and rolling techniques can create curves and shapes that would be impossible with traditional methods. Finally, finishing processes such as polishing and powder coating can add the final touch to your Sheet metal customization creation.

If you’re looking for inspiration for your next creative project, look no further than Sheet metal customization fabrication. From intricate architectural details to eye-catching sculptures, the possibilities are endless. Case studies of successful projects can provide valuable insights and ideas for your own creations. Tips for brainstorming ideas include looking to nature for inspiration, experimenting with different materials and finishes, and thinking outside the box when it comes to design. And don’t be afraid to incorporate custom sheet metal into different industries, from fashion to furniture to technology.

When choosing a Custom Sheet Metal fabricator to bring your project to life, there are a few key considerations to keep in mind. Communication and collaboration are essential for ensuring that your vision is accurately translated into the final product. Setting a clear budget and timeline upfront can help prevent delays and unexpected costs. Quality control and inspections throughout the fabrication process will ensure that your Custom Sheet Metal creation meets your expectations.

As technology continues to advance, the future of Sheet metal customization fabrication looks bright. Digital fabrication technologies such as laser cutting and CNC machining are making it easier than ever to create complex designs with precision and accuracy. Sustainable materials and practices are becoming increasingly important in the fabrication industry, leading to the development of eco-friendly options for custom sheet metal projects. Integration with 3D printing is also on the rise, allowing for even more customization and creativity. And with the advent of AI and automation, the customization possibilities for Sheet metal customization fabrication are virtually limitless.

In conclusion, custom sheet metal fabrication is a versatile and exciting process that offers a wide range of benefits for creative projects. From its durability and customization options to its unique designs and shapes, Sheet metal customization is a popular choice for a variety of industries and applications. By working with a skilled fabricator and considering key design considerations, you can unleash your creativity and bring your vision to life. So why wait? Take the first step towards your next project with custom sheet metal today.