In the world of metalworking, sheet metal tools play a crucial role intricate designs. From shaping and cutting to bending and forming, the right tools can elevate your metalworking skills to new heights. In this article, exploring the diverse available to craft enthusiasts and professionals alike.

When it comes to working with sheet metal, hand tools are essential for precision and finesse. Snips, hammers, and seamers are invaluable tools for shaping and sculpting metal with ease. Snips come in various shapes and sizes, designed for cutting metal with precision and accuracy. Hammers are use for forming and shaping metal, while seamers are ideal for bending and folding metal into intricate shapes.

For larger projects and efficient metalworking, power tools are a game-changer. Angle grinders, electric shears, and metal cutting saws are powerful tools that can cut through like butter. Angle grinders are versatile tools that can be use for cutting, grinding, and polishing metal. Electric shears are perfect for cutting straight lines and curves with ease. Metal cutting saws are ideal for cutting through thick sheets of metal quickly and accurately.

Brake machines are essential for bending and shaping sheet metal with precision. There are various types of brakes, including box brakes, pan brakes, and press brakes, each designed for different types of metalworking projects. Learning how to use a brake machine effectively is crucial for achieving clean bends and consistent results in your metalwork.

Shearing machines, such as guillotine shears and bench shears, are use for cutting straight lines in sheet metal. Guillotine shears are powerful machines that can cut through thick metal with ease, while bench shears are versatile tools that can be use for smaller, intricate cuts. These machines are essential for achieving clean and precise cuts in sheet metal projects.

Roll forming machines are used for shaping and forming sheet metal into complex profiles and designs. The roll forming process involves feeding a sheet of metal through a series of rollers to gradually shape the metal into the desired form. The benefits of using roll forming machines include increased efficiency, precision, and consistency in metalworking projects.

Deburring is an essential step in metalworking to remove sharp edges and burrs from sheet metal. Deburring tools, including handheld and benchtop options, are designed to smooth out rough edges and create a clean finish on metal surfaces. Proper deburring is crucial for achieving professional-looking results in metalworking projects.

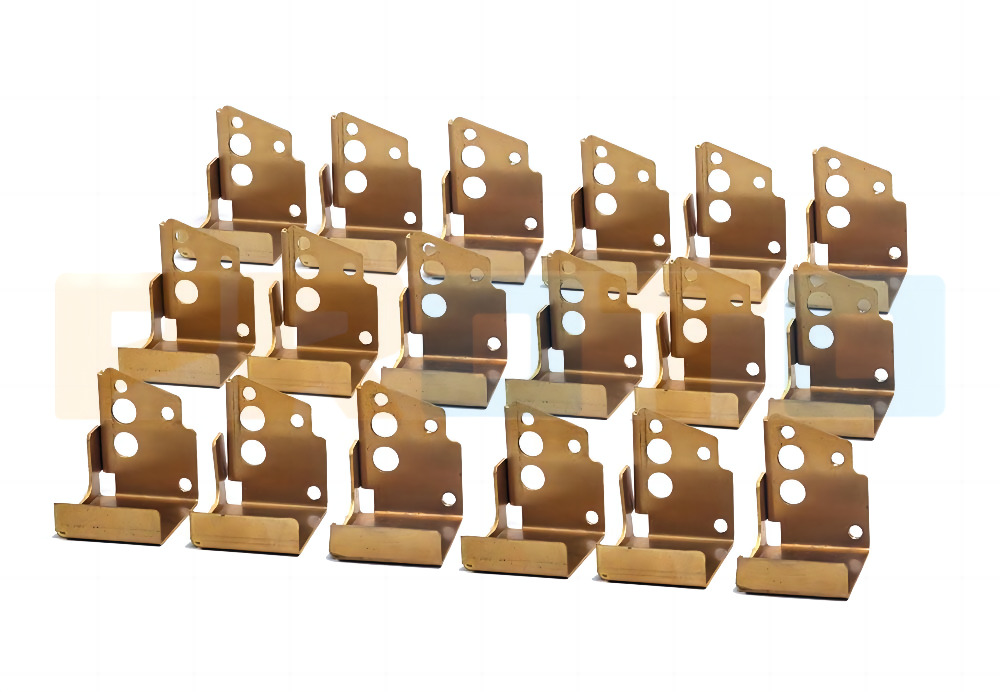

Notching tools, such as tube notchers and corner notchers, are used for cutting precise holes and shapes in sheet metal. Tube notchers are ideal for creating holes and slots in cylindrical metal tubes, while corner notchers are perfect for cutting precise corners and edges. These tools are essential for adding intricate details and contours to metalwork projects.

When selecting sheet metal tools, there are several factors to consider to ensure you choose the right tools for your projects. Factors such as the type of metal being used, the complexity of the project, and your skill level should be taken into account when selecting tools. Quality and durability are crucial aspects to consider when investing in sheet metal tools, as they can impact the outcome.

Safety should always be a top priority when working with sheet metal tools. It is important to follow safety precautions, such as wearing protective gear, using tools properly. Proper tool maintenance and storage are also essential to ensure the longevity of your tools and prevent accidents. By following best practices and safety measures, you can create a safe and efficient working environment for your metalworking projects.

With the right sheet metal tools, you can explore advanced techniques and applications to take your metalworking skills to the next level. Creating intricate designs with cutting-edge tools, such as laser cutters and CNC machines, allows for precise and detailed metalwork projects. Bending and shaping tools, such as press brakes and roll forming machines, can be used to achieve unique and complex designs in sheet metal projects.

To inspire your creativity and push the boundaries of your metalworking skills, we have compiled a showcase of successful projects using sheet metal tools. From sculptures and art installations to architectural structures and automotive components, these projects demonstrate the versatility and creativity that can be achieved with the right tools and equipment.

In conclusion, sheet metal tools are essential for any metalworking project, from simple DIY crafts to complex industrial applications. By exploring the diverse range of tools and equipment available, you can unleash your creativity and elevate your metalworking skills to new heights. With the right tools, safety measures, and inspiration, there is no limit to what you can achieve in the world of sheet metal. So, go ahead, experiment, and push the limits of your metalworking skills to create stunning and innovative projects that showcase the power of sheet metal tools.