Sheet metal fabrication is a vital process in the manufacturing industry, involving the shaping and manipulation of thin metal sheets to create a wide range of products. From automotive components to architectural structures, sheet metal plays a crucial role in various industries due to its durability, strength, and cost-effectiveness.

The origins of sheet metal fabrication can be traced back to ancient civilizations, where metals like copper and bronze were used to create tools and decorative items. Over time, techniques for working with sheet metal have evolved, with advancements in technology leading to more efficient and precise fabrication methods.

There are several common types of sheet metal used in fabrication, including aluminum, steel, and copper. These metals can be categorized into two main groups: ferrous metals, such as steel, which contain iron, and non-ferrous metals, like aluminum and copper, which do not.

Fabrication One of the key advantages of sheet metal is its durability and strength, making it ideal for applications where structural integrity is essential. Additionally, sheet metal fabrication is cost-effective compared to other materials, offering manufacturers a cost-efficient solution for producing high-quality products.

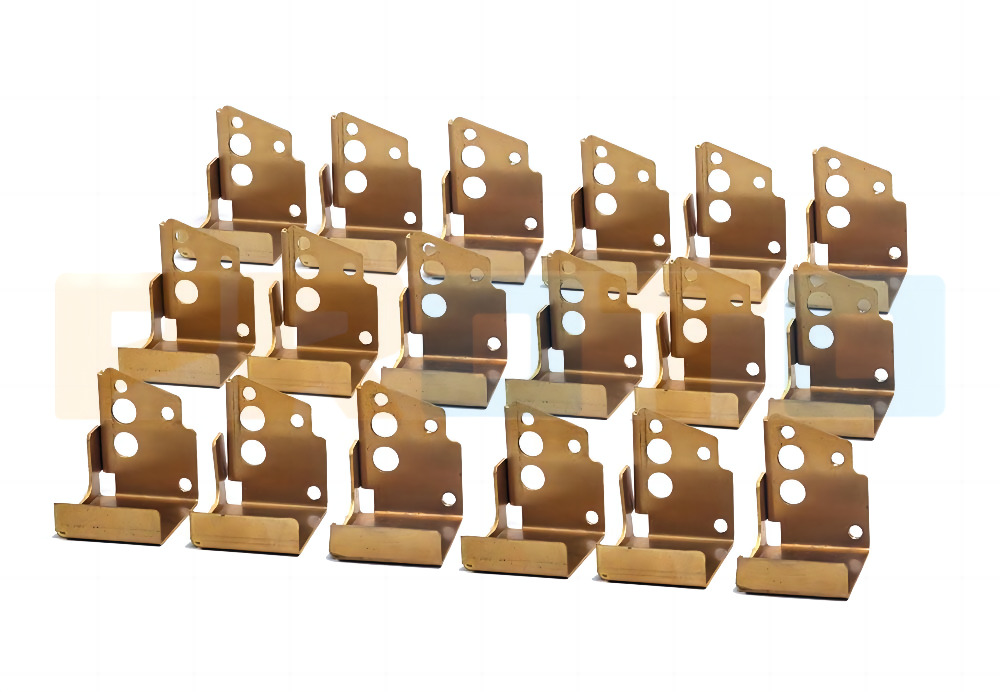

Essential tools for shaping and cutting sheet metal include shears, brakes, and punches, which help in forming precise shapes and bends. Advanced machinery, such as laser cutters and CNC machines, are also used in modern fabrication processes to increase efficiency and accuracy.

Bending and folding techniques are commonly used to shape sheet metal into desired forms, while welding and soldering methods are employed to join metal pieces together. These techniques require skill and precision to ensure the quality of the final product.

In the automotive industry, sheet metal is used to manufacture vehicle bodies, chassis components, and engine parts due to its strength and versatility. In construction and architecture, sheet metal is utilized in roofing, cladding, and structural applications, adding both functionality and aesthetic appeal to buildings.

Common issues faced in working with sheet metal include deformation, warping, and cracking during the forming process. Manufacturers must employ strategies such as proper material handling and tool maintenance to overcome these challenges and ensure the quality of the finished product.

Automation and robotics have revolutionized modern fabrication processes, allowing for increased efficiency and precision in handling sheet metal. Sustainable practices, such as recycling scrap metal and reducing waste, are also becoming increasingly important in sheet metal production.

Future Trends in Sheet Metal Industry Advancements in 3D printing technology are poised to transform metal fabrication by enabling complex and intricate designs with minimal waste. Integration of artificial intelligence and Internet of Things (IoT) technology will further enhance efficiency and productivity in sheet metal processes.

Precision and accuracy are crucial in sheet metal work to ensure the structural integrity and functionality of the final product. Inspection and testing methods, such as visual inspection, dimensional measurement, and non-destructive testing, help to maintain quality standards in fabrication.

Case Studies: Successful Sheet Metal Projects From innovative architectural structures to cutting-edge automotive designs, there are countless examples of successful sheet metal projects that showcase the versatility and creativity of this material. These projects have not only pushed the boundaries of what is possible with sheet metal but have also contributed to industry growth and innovation.

In conclusion, sheet metal fabrication plays a vital role in modern industries, offering a versatile and cost-effective solution for producing a wide range of products. As technology advances and new innovations emerge, the future of sheet metal fabrication looks promising, with endless possibilities for creative and sustainable applications. By understanding the history, benefits, techniques, and challenges of sheet metal fabrication, manufacturers can harness the power of this material to drive industry growth and innovation.