Proto tooling is a critical component in the realm of product development, acting as a catalyst for innovation and success. By exploring the various facets of prototyping, we can gain insight into the impact it has on shaping the products of tomorrow.

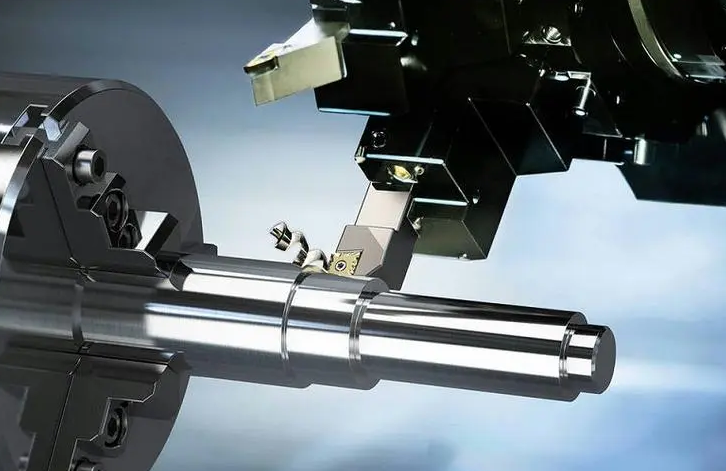

Proto tooling, also known asprototyping, is the process of creating molds and tools to produce prototypes of components or products before full-scale production begins. This allows for testing and validation of designs, materials, and manufacturing processes. Various types of prototyping are available, including 3D printing, CNC machining, and injection molding.

One of the primary advantages of utilizing prototyping is the ability to speed up the product development timeline. By quickly producing prototypes, designers and engineers can iterate on their designs more efficiently, ultimately reducing time to market. Additionally, prototyping helps minimize costs by identifying issues early in the development process, saving both time and resources. Furthermore, prototyping enhances product testing and validation processes, ensuring that the final product meets quality standards.

Proto tooling is widely used across various industries, including automotive, aerospace, electronics, and medical devices. In the automotive industry, prototyping is essential for developing new vehicle components and enhancing performance. Aerospace companies rely on prototyping to test the durability and functionality of aircraft parts. In the electronics sector, prototyping enables rapid prototyping of circuit boards and electronic devices. And in the medical device industry, prototyping is crucial for creating prototypes of life-saving equipment.

When selecting a prototyping partner, it is essential to consider factors such as expertise, capabilities, and reliability. Collaboration and communication with prototyping experts are key to ensuring a successful partnership. By working closely with a trustedprototyping partner, companies can achieve their product development goals effectively.

Several companies have seen significant benefits from implementing prototyping in their product development processes. For example, a leading automotive manufacturer utilized prototyping to test new vehicle designs quickly and efficiently, resulting in faster time to market. By leveraging prototyping, these companies have been able to innovate and stay ahead of the competition in their respective industries.

The future of prototyping is poised for exciting advancements, with artificial intelligence playing a significant role in enhancing the prototyping process. Sustainability and environmental impact considerations will also be crucial factors in shaping prototyping processes moving forward. Emerging technologies such as additive manufacturing and virtual prototyping are set to revolutionize the way products are developed using prototyping.

While prototyping offers numerous benefits, manufacturers may face challenges such as design complexity, material selection, and production scalability. By implementing strategies such as design optimization, collaboration with suppliers, and continuous process improvement, these challenges can be overcome, leading to optimized prototyping processes.

Proto tooling enables rapid prototyping and iteration, allowing companies to test and refine their product designs quickly. By leveraging prototyping for continuous product improvement, companies can drive innovation and stay competitive in the market. The iterative nature of prototyping promotes a culture of innovation and creativity within organizations.

In conclusion, prototyping plays a vital role in accelerating product development, driving success, and fostering innovation. By understanding the benefits, applications, and future trends in prototyping, companies can harness its potential to create groundbreaking products that shape the future of industries worldwide. Through collaboration, communication, and strategic partnerships, the possibilities with prototyping are endless.