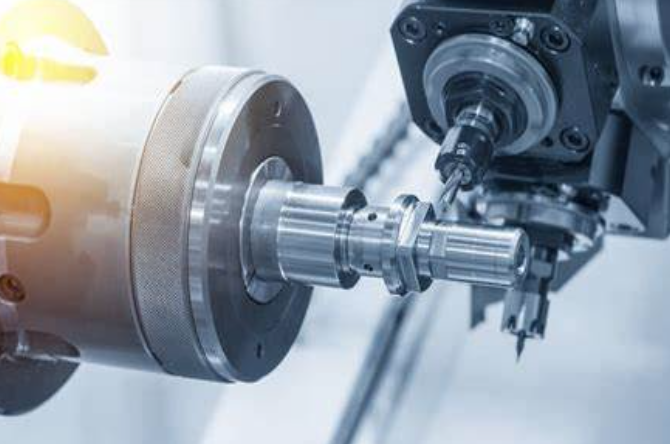

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that utilizes automated machinery to produce precision parts and components. Understanding the challenges faced in this industry is crucial for businesses looking to stay ahead of the competition and deliver high-quality products. In this article, we will delve into the limitations and obstacles encountered in the world of CNC machining, as well as explore the latest trends and solutions to overcome these challenges.

The roots of CNC machining can be traced back to the 1940s when the first computer-controlled machines were developed for military applications. Over the years, advancements in technology have revolutionized the industry, allowing for greater accuracy, efficiency, and versatility in machining processes. Today, CNC machining is a cornerstone of modern manufacturing, driving innovation across various sectors.

Precision and accuracy issues are fundamental challenges in CNC machining, as achieving tight tolerances and complex geometries can be demanding. Material limitations and compatibility also pose obstacles, as different materials require specialized tooling and cutting techniques. Furthermore, tool wear and maintenance are ongoing challenges that impact the productivity and cost-effectiveness of CNC operations.

To address these challenges, the industry is embracing cutting-edge technologies such as artificial intelligence (AI) and machine learning. These tools enable predictive maintenance, optimize machining parameters, and enhance overall process control. Automation and robotics are also playing a significant role in streamlining operations and increasing efficiency. Smart manufacturing solutions, integrating IoT devices and data analytics, provide real-time insights for continuous improvement.

In addition to technical challenges, CNC machining companies are increasingly focusing on sustainability practices. Energy consumption and waste management are critical considerations, prompting the adoption of green machining techniques and sustainable material sourcing. By reducing environmental impact, companies can minimize their carbon footprint and contribute to a more eco-friendly manufacturing environment.

The shortage of skilled CNC operators is a pressing concern in the industry, highlighting the need for comprehensive training programs and continuous education initiatives. Upskilling the workforce and bridging the skills gap through certifications and specialized training courses are essential for ensuring operational excellence and competitiveness in the market.

In a highly regulated industry like CNC machining, adherence to standards and certifications is paramount. Compliance with safety regulations and quality assurance processes safeguards both workers and end-users from potential hazards. Implementing robust quality control measures ensures consistency and reliability in product output.

Managing costs and optimizing efficiency are key priorities for CNC machining businesses aiming to stay profitable. Implementing cost-effective machining strategies, such as batch processing and tool life optimization, can lead to significant savings. Streamlining production processes, minimizing downtime, and maximizing productivity are essential for maintaining a competitive edge.

The global market for CNC machining is experiencing steady growth, driven by increased demand for customized parts and components across industries. Regional market dynamics play a crucial role in shaping trends and opportunities, with emerging markets offering new growth prospects for industry players. Staying abreast of market trends and leveraging opportunities for expansion are vital for sustained success.

Success stories in the CNC machining industry highlight best practices and strategies that have proven effective in addressing challenges. Real-world examples provide valuable insights into overcoming obstacles, implementing innovative solutions, and achieving operational excellence. By learning from these case studies, businesses can adapt and thrive in a competitive marketplace.

Looking ahead, the future of CNC machining is filled with exciting possibilities. Emerging technologies like 3D printing, nanotechnology, and Internet of Things (IoT) are poised to transform the industry landscape. Predictions for the industry include enhanced automation, increased customization, and improved efficiency through digitalization. Opportunities for growth and innovation abound for companies willing to embrace change and invest in technological advancements.

In conclusion, navigating the challenges of CNC machining requires a comprehensive understanding of industry trends, technical advancements, and best practices. By staying informed, adapting to changes, and continuously improving processes, businesses can overcome obstacles and thrive in a competitive market. The call to action for CNC machining companies is to embrace innovation, prioritize sustainability, and invest in skills development to achieve long-term success in the ever-evolving manufacturing landscape.